Superalloys and parts formed therefrom

A superalloy, nickel-based superalloy technology, applied in the nickel-based superalloy to show improved high temperature holding pressure, nickel-based superalloy field, can solve the complex, creep and crack growth characteristics, it is difficult to improve creep at the same time and crack growth characteristics to achieve good thermal stability and good productivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

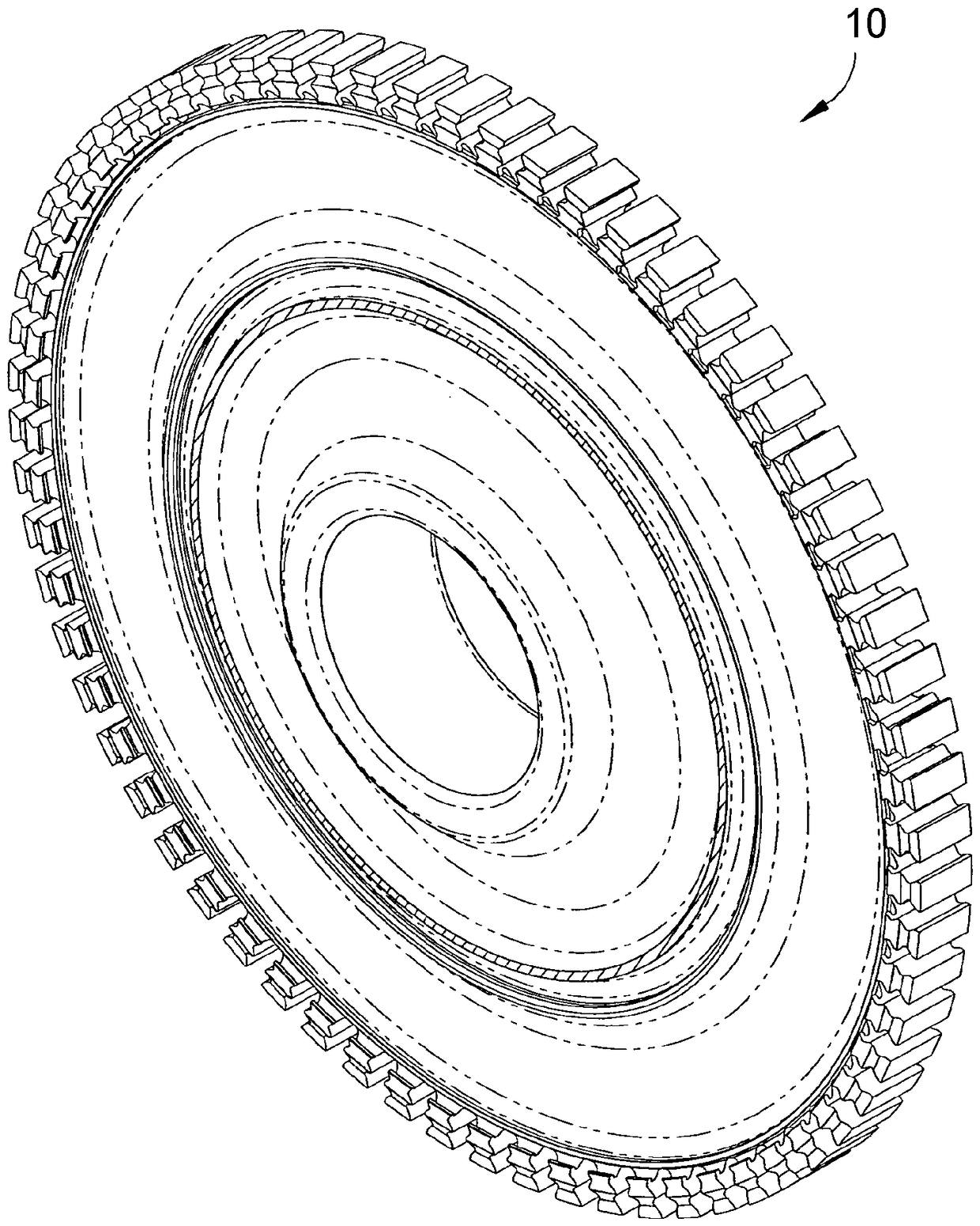

[0020] The present invention relates to γ′ nickel-based superalloys, and in particular those γ′ nickel-based superalloys suitable for use in components produced by hot working operations such as forging to have a polycrystalline microstructure. figure 1 A specific example shown in is a high pressure turbine disk 10 for a gas turbine engine. The present invention will be discussed with reference to the machining of high-pressure turbine disks for gas turbine engines, although those skilled in the art will appreciate that the teachings and benefits of the present invention are also applicable to compressor disks and blisks for gas turbine engines, as well as those subjected to high temperatures. Many other components that are stressed and therefore require high temperature pressure holding capabilities.

[0021] figure 1Discs of the type shown in are typically produced by isothermally forging fine-grained billets formed by powder metallurgy (PM), casting and forging processes o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com