Copper-silicon negative electrode and preparation method therefor

A copper-silicon and anode technology, applied in electrode manufacturing, battery electrodes, electrical components, etc., can solve the problems of limited efficiency improvement of silicon anode materials, affecting the performance of lithium-ion batteries, reducing the conductivity of the pole piece, and reducing the thickness of the pole piece. , referring to the volume energy density, the effect of reducing the thickness of the pole piece

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] The preparation of copper-silicon composite active material: copper acetate (31g) is completely dissolved in the mixed solution of dehydrated alcohol and deionized water as copper source, takes by weighing silicon powder (6g) and joins in the mixed solution of copper acetate, finally An aqueous polyacrylic acid solution (6 g) was added to the above solution as a surfactant. The prepared solution is prepared by spray drying, and the spray drying is carried out under nitrogen atmosphere at 160°C. Then, the composite material was kept at 300° C. under a hydrogen atmosphere for 6 hours to undergo a reduction reaction to prepare a copper-silicon composite.

[0066] Preparation of metal compound copper oxide: Weigh 40g of copper acetate or organic acid copper salt solution, water, and 31g of ammonia solution, mix the above aqueous solutions, and spray-dry the mixed solution in air at 180°C to prepare Cu(OH ) 2 Powder, Cu(OH) 2 CuO, Cu 2 O powder.

[0067] Preparation of ...

Embodiment 2

[0070] The preparation of the copper-silicon composite is the same as in Example 1, and the preparation of copper oxide is the same as in Example 1.

[0071] Preparation of copper-silicon composite pole piece: mix copper-silicon composite (0.3g), copper oxide (0.1g), and bonding reducing agent polyethylene glycol aqueous solution (2g) to prepare a slurry, and apply the slurry to Cu Prepare the pole piece on the foil current collector, dry the pole piece and use 10MPa / cm 2 pressure preload.

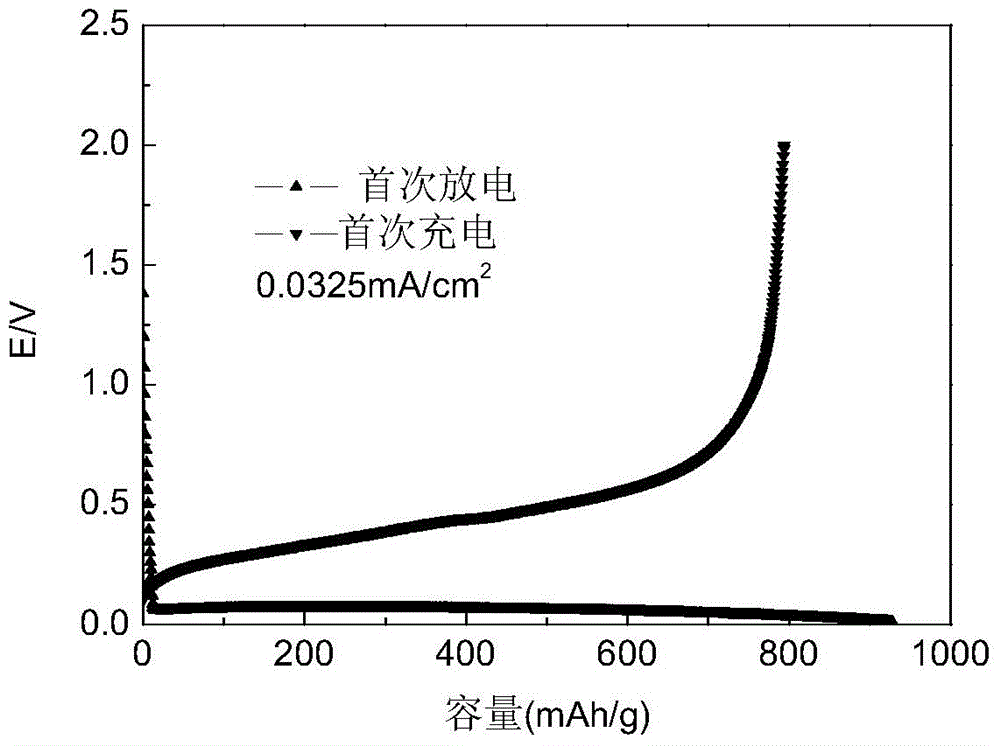

[0072] Electrode welding: place the above-mentioned pole piece in a nitrogen furnace, keep it at 500°C for 6 hours for welding, then reduce it with hydrogen at 300°C for 2 hours, and then heat it at 5MPa / cm 2 Under the final pressure, the pole pieces were compacted and cut into discs with a diameter of 14mm for assembling button batteries (lithium pieces as the counter electrode). For the test results of the button battery test, see figure 2 shown. Depend on figure 2 It can be seen ...

Embodiment 3

[0074] Preparation of copper-silicon composite active material: Copper acetate (31g) is dissolved in the mixed solution of absolute ethanol and deionized water as the copper source, weighs silicon (2.5g) and joins in the mixed solution of copper acetate, and finally An aqueous solution of polyacrylic acid (6 g) was added to the above mixed solution as a surfactant. The prepared mixed solution was spray-dried to prepare the composite material, and the spray-dried nitrogen atmosphere was used at a temperature of 160°C; then the composite material was kept at 300°C in a hydrogen atmosphere for 6 hours to undergo a reduction reaction to prepare a copper-silicon composite. Copper powder for preparing copper-silicon composite can be used as soldering agent at the same time.

[0075] Preparation of copper-silicon composite pole piece: Mix positive electrode material copper-silicon composite (0.8g), PAA aqueous solution (0.3g,) and deionized water (1g) to prepare a slurry, and apply t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com