IGBT device and fabrication method thereof

A manufacturing method and device technology, which are used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., to achieve the effects of improving capacitance, improving stability, and realizing electron injection enhancement effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

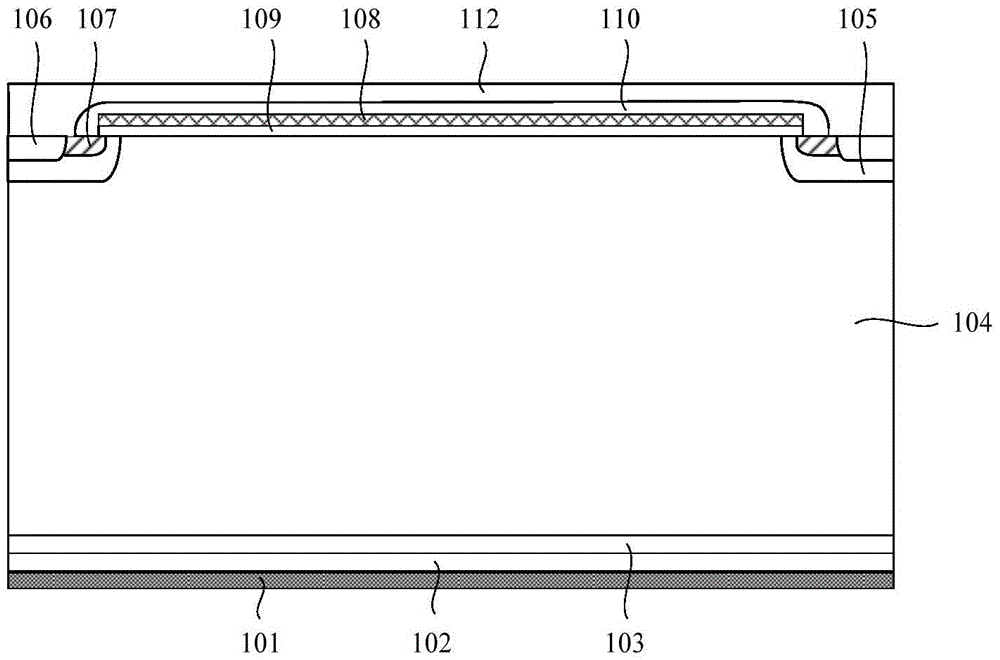

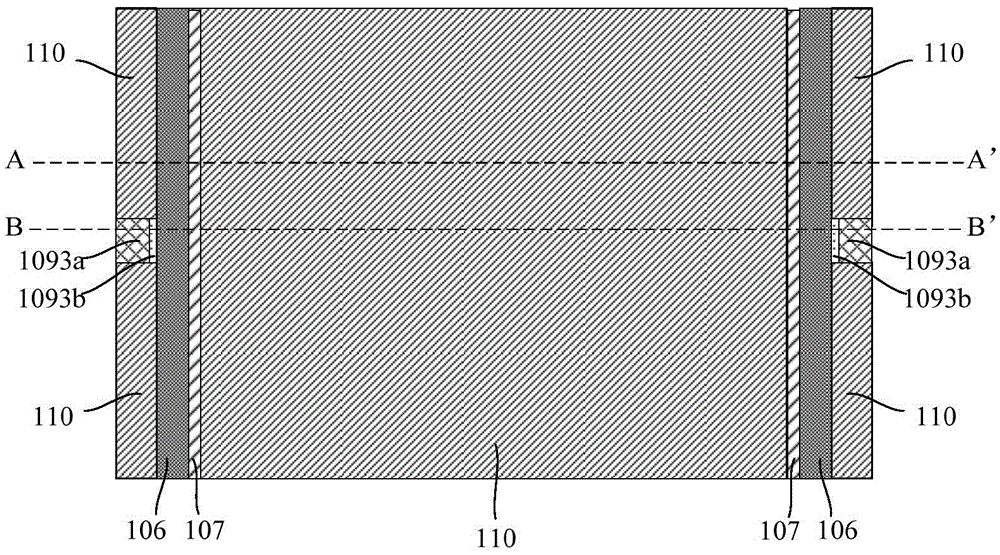

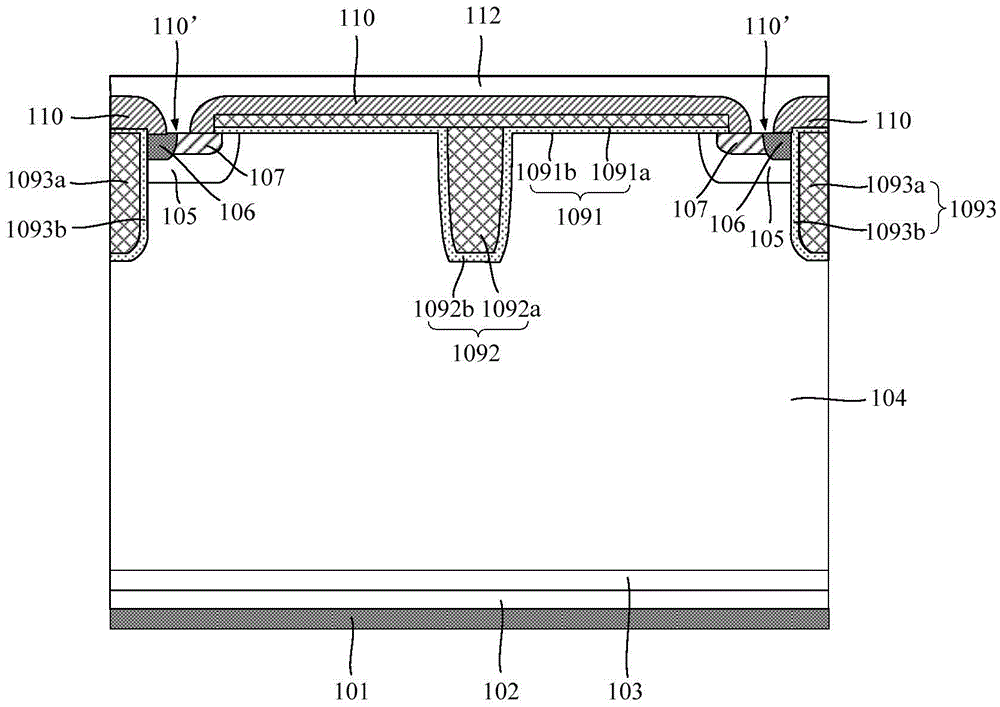

[0056] As mentioned in the background technology, in order to realize the electron injection enhancement effect (IE effect), the traditional planar gate structure IEGT requires a long polycrystalline gate length, resulting in a low cell density and a large device area. Although the structure can increase the device cell density and eliminate the JFET effect, it will increase the gate capacitance and affect the switching speed and turn-off loss. For this reason, the composite gate structure is adopted in the IGBT device of the present invention, and the composite gate structure includes a planar gate formed on the front surface of the semiconductor substrate and a trench gate formed in the front surface of the semiconductor substrate. The slot gate can increase the effective length of the gate of the IGBT device, so the purpose of enhancing the effect of electron injection can be achieved while reducing the length of the planar gate and reducing the size of the cell. In additio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com