Integrated optimization method of continuous agitated vessel reaction process technology design and control

A technology of reaction process and process design, applied in the direction of program control, comprehensive factory control, electrical program control, etc., can solve complex problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example

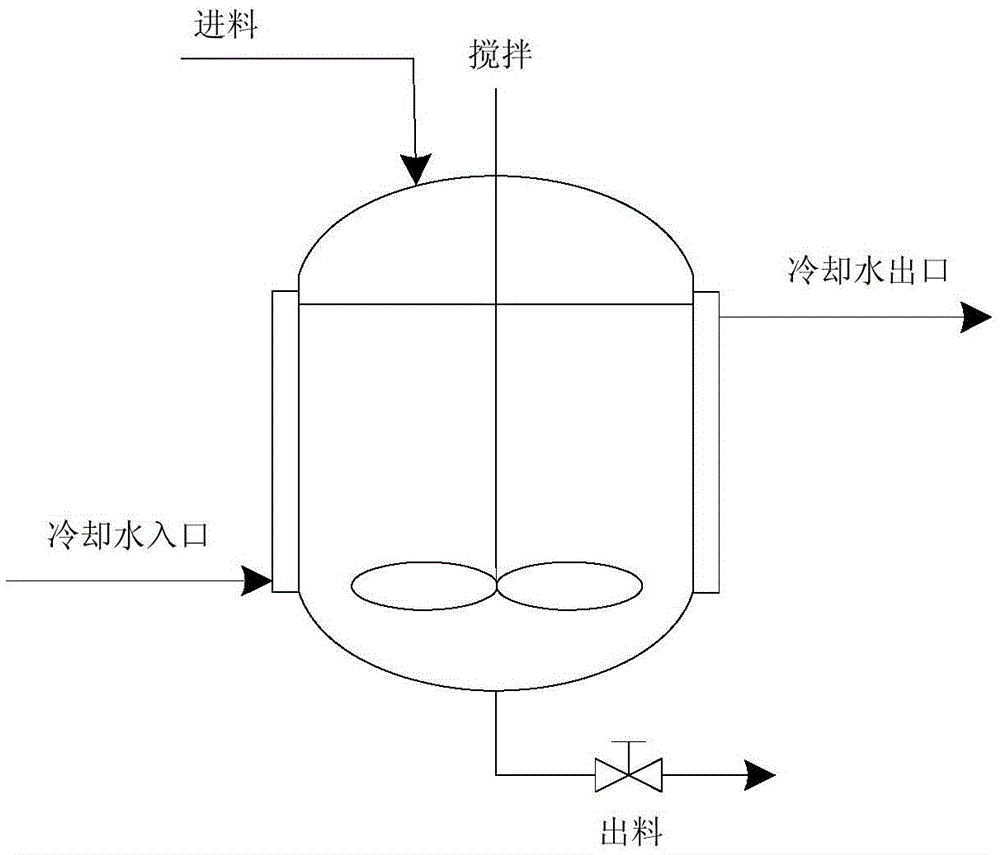

[0115] Such as image 3 Shown is a CSTR process. Assuming that a first-order irreversible exothermic reaction A→B occurs in the CSTR, the reaction temperature and the outlet concentration of the reactant are regulated by the jacket cooling water flow. According to the material balance and energy balance, there are the following strongly nonlinear state equations:

[0116] dC A d t = F V ( C A , 0 - C A ) - C A K 0 e - E R T ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com