Deepwater pipe-in-pipe buckle arrestor based on CX section deformation elements

A deformation element and pipe-in-pipe technology, which is applied in the direction of pipeline damage/abrasion prevention, pipeline protection, pipeline laying and maintenance, etc., can solve problems such as inconvenient manufacturing and installation, local damage cannot be restored, welding defect stress, etc., to achieve reduction Small stress, convenient storage and transportation, good flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

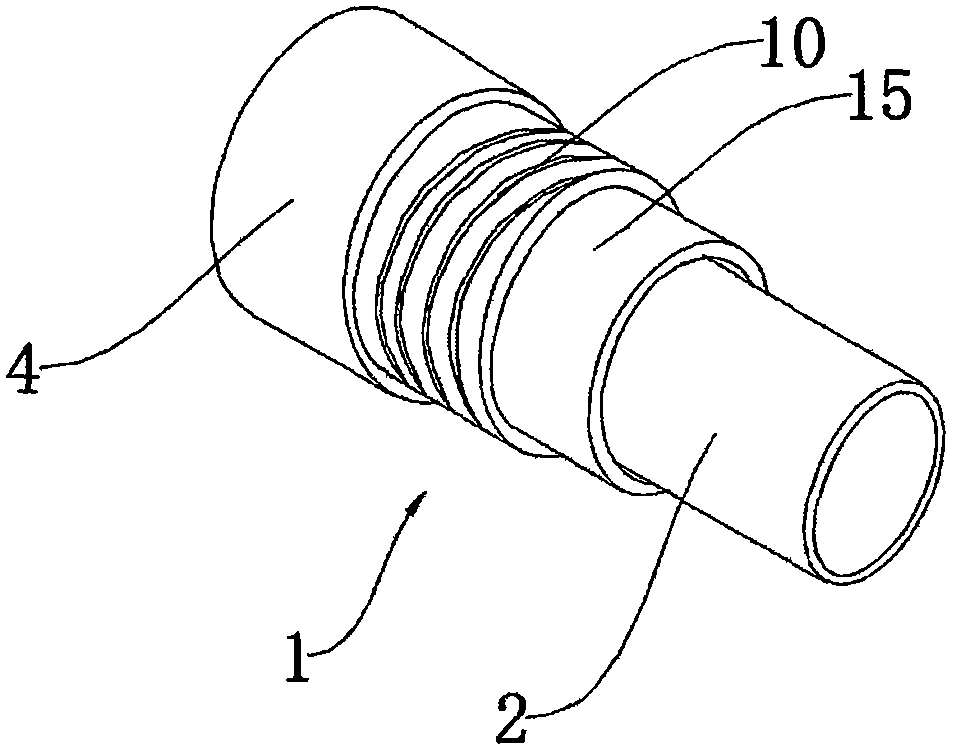

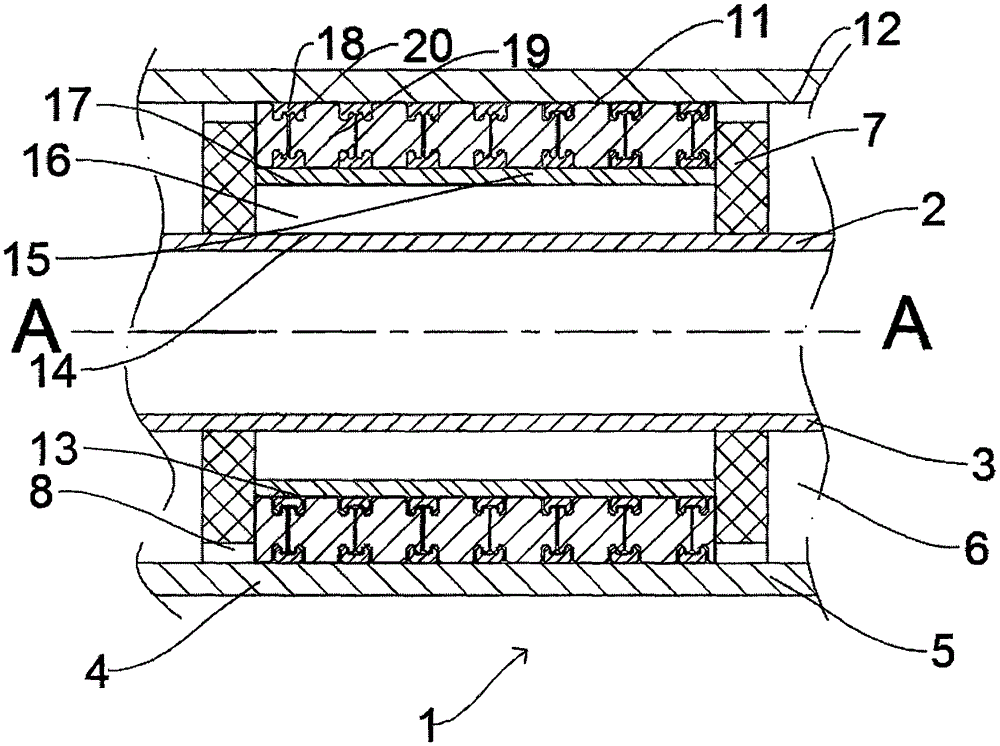

[0025] like figure 1 As shown, the tube-in-tube 1 is composed of an inner tube 2 and an outer tube 4 . The CX section deformation element 10 is helically wound in the annular space between the inner and outer pipes at an angle close to 90 degrees to the length direction of the pipe, and its outer surface has at least two points of contact with the inner wall of the outer pipe, and the inner surface is not separated from the outer surface of the inner pipe. touch.

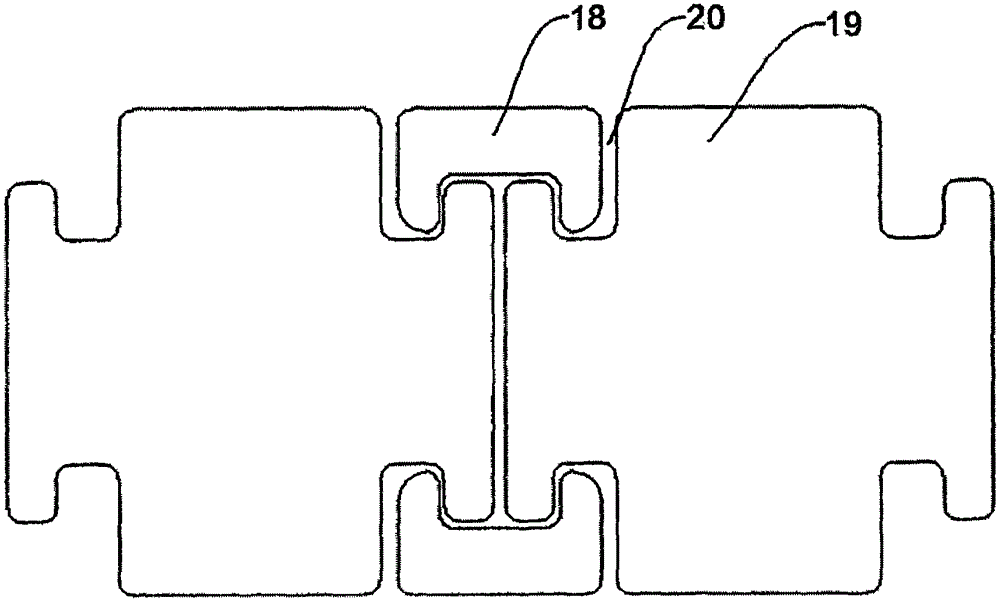

[0026] like figure 2 As shown, the central axis of the tube-in-tube 1 is AA. In the annular space 6 of the inner tube 2 and the outer tube 4, the nuclear type buckle arrester according to the present invention is installed. The nuclear type buckle arrester consists of a spacer ring 7, one or more deformation elements 10 ( figure 1 , whose cross-section is figure 2 shown in 18, 19) a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com