Device used for preventing drawn slivers from being accidently stretched and applied to roving frame

A roving frame, unexpected technology, applied in textiles and papermaking, etc., can solve problems such as unexpected elongation, affecting enterprise benefits, unevenness of roving weight and increase in unevenness of evenness, and achieves wide application range and low investment cost. Small and easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

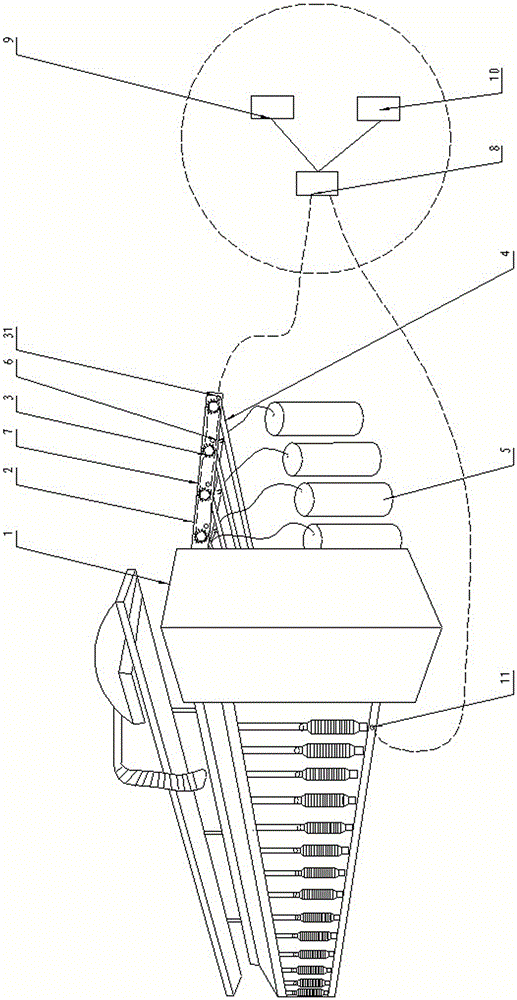

[0009] The device for preventing the unexpected elongation of the sliver of the roving frame of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0010] Depend on figure 1 It can be seen that the anti-cooked sliver elongation prevention device of the roving frame of the present invention comprises a roving frame 1 and a creel 2 arranged thereon, and the creel 2 is provided with several sprockets 3 and several sliver rollers 4 , the bottom of some guide rollers 4 is provided with some cans 5, and each guide roller 4 is provided with a slitting device 6; said several sprockets 3 are connected by chains 7, and said several sprockets 3 are A dynamic sensor 31 is provided, and the roving frame 1 is also provided with a bobbin dynamic sensor 11. Both the dynamic sensor 31 and the bobbin dynamic sensor 11 are connected to the input end of the PLC programmable controller 8 through wires, and the PLC programmable controller...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com