Method for fermentation production of bacitracin

A technology of bacitracin and fermentation liquid, which is applied in the field of fermentation engineering, can solve the problems of unstable fermentation process and low fermentation level, and achieve the effects of increasing bacitracin production, increasing production, and increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

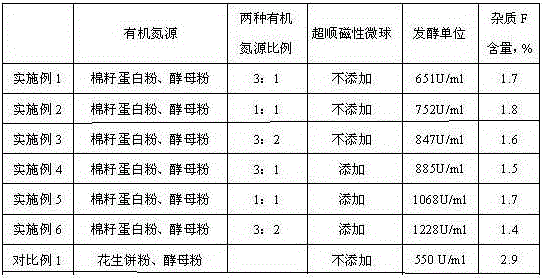

Examples

Embodiment 1、500

[0029] Embodiment 1, 500mL shake flask fermentation prepares bacitracin

[0030] Preparation of Seed Solution of Bacillus licheniformis Strain

[0031] The slant culture of the Bacillus licheniformis strain was inoculated into the seed medium, and cultured at 28° C. and 240 rpm for 24 hours to obtain a seed liquid.

[0032] The seed medium described therein is obtained by the following method: 3.0 grams of cornstarch, 20.0 grams of glucose, 20.0 grams of yeast powder, 1.0 grams of ammonium sulfate, 2.0 grams of sodium chloride, 1.0 grams of magnesium sulfate heptahydrate, add tap water to be constant to 1000mL, pH6.5, sterilized at 121°C for 30min.

[0033] The bacitracin producing bacterium of the present invention is the strain numbered ATCC10716.

[0034] Fermentation medium composition:

[0035] 30.0 grams of corn starch, 20.0 grams of glucose, 30.0 grams of cottonseed protein powder, 10.0 grams of yeast powder, 3.0 grams of ammonium sulfate, 5.0 grams of corn steep liq...

Embodiment 2、5

[0038] Embodiment 2, 5L tank fermentation prepares bacitracin

[0039] Preparation of Seed Solution of Bacillus licheniformis Strain

[0040] The slant culture of the Bacillus licheniformis strain was inoculated into the seed medium, and cultured at 30° C. and 200 rpm for 20 hours to obtain a seed liquid.

[0041] The seed medium described therein is obtained by the following method: 5.0 grams of cornstarch, 10.0 grams of glucose, 10.0 grams of yeast powder, 2.0 grams of ammonium sulfate, 2.0 grams of sodium chloride, 1.5 grams of magnesium sulfate heptahydrate, add tap water to be constant to 1000mL, pH7.0, sterilized at 121°C for 30min.

[0042] The bacitracin producing bacterium of the present invention is the strain numbered ATCC10716.

[0043] Fermentation medium composition:

[0044] 90.0 grams of corn starch, 60.0 grams of glucose, 45.0 grams of cottonseed protein powder, 45.0 grams of yeast powder, 6.0 grams of ammonium sulfate, 12.0 grams of corn steep liquor, 4.5 ...

Embodiment 3、10

[0047] Embodiment 3, 10L tank fermentation prepares bacitracin

[0048] Preparation of Seed Solution of Bacillus licheniformis Strain

[0049] The slant culture of the Bacillus licheniformis strain was inoculated on the seed medium, and cultured at 28° C. and 220 rpm for 28 hours to obtain a seed solution.

[0050] The seed medium described therein is obtained by the following method: 4.0 grams of cornstarch, 15.0 grams of glucose, 15.0 grams of yeast powder, 1.0 grams of ammonium sulfate, 1.0 grams of sodium chloride, 1.0 grams of magnesium sulfate heptahydrate, add tap water to be constant to 1000mL, pH6.8, sterilized at 121°C for 30min.

[0051] The bacitracin producing bacterium of the present invention is the strain numbered ATCC10716.

[0052] Fermentation medium composition:

[0053] 200.0 grams of corn starch, 50.0 grams of glucose, 150.0 grams of cottonseed protein powder, 100.0 grams of yeast powder, 10.0 grams of ammonium sulfate, 15.0 grams of corn steep liquor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com