A pre -coating film

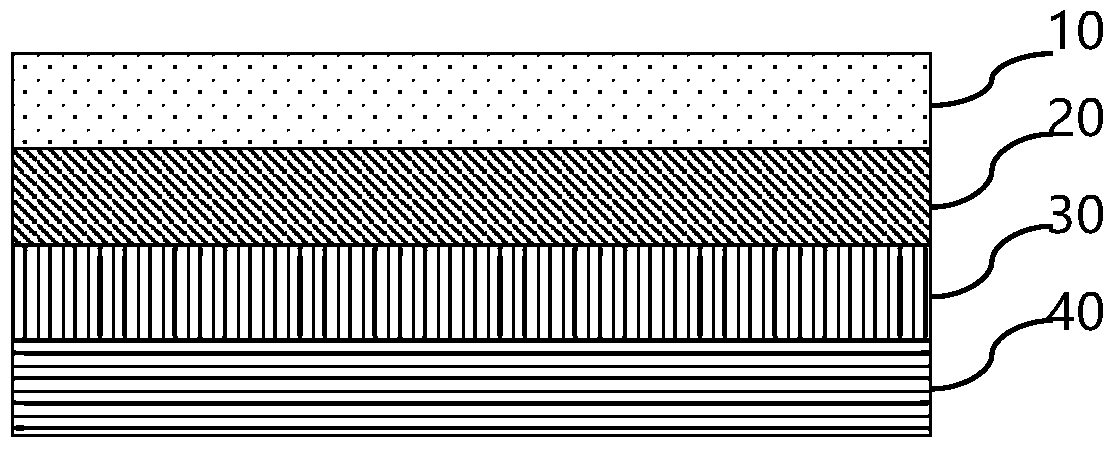

A scratch-resistant, pre-coated film technology, applied in the printing field, can solve the problems of insufficient bonding between printed matter and film, high content of inorganic components, and difficulty in hot-melt adhesive bonding, etc., to increase color diversity and enhance wear resistance Scratch ability, energy saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] Embodiment one, make black anti-scratch nylon precoat film:

[0055] Adopt the polycarbonate polyurethane dispersion of 30 weight parts, the basic magnesium sulfate whisker of 0.01 weight part, the self-dulling polyurethane resin of 70 weight parts, the ionic polyacrylate solution of 0.05 weight part, 0.1 weight part does not contain Antifoaming agent for silicone and mineral oil, 3 parts by weight of aziridine cross-linking curing agent, no thickener, 5 parts by weight of water and ethanol 1:1 mixed solvent to adjust the viscosity of the system, high-speed stirring to mix evenly .

[0056] Then the water-based coating solution is pumped into the intermediate tank through the liquid supply pump.

[0057] A 22-micron nylon film is selected as the substrate layer, and after the nylon film is stretched longitudinally by a stretching device, the surface of the nylon film is subjected to corona treatment by a corona device, and the power of the corona machine is selected as...

Embodiment 2

[0064] Example 2, red anti-scratch polypropylene tackifying precoat film:

[0065] Wherein the coating solution comprises: 60 parts by weight of polyether polyurethane dispersion, 5 parts by weight of potassium titanate whiskers, 55 parts by weight of self-dulling polyurethane resin, 0.15 parts by weight of ionic polyacrylate solution, 0.3 parts by weight of Defoamer for silicone and mineral oil; 15 parts by weight of HDI-IPDI composite trimer curing agent, 0.15 parts by weight of associative polyurethane thickener, without adding water.

[0066] Then the water-based coating solution is pumped into the intermediate tank through the liquid supply pump.

[0067] 15 micron polypropylene film is selected for the substrate layer. After the polypropylene film is stretched longitudinally by a stretching device, a corona device is required to perform corona treatment on the surface of the polypropylene film. The strength of the corona machine is selected as 0.8KW. At the same time, t...

Embodiment 3

[0075] Example 3, blue anti-scratch polyester digital pre-coating film:

[0076] Adopt the fatty acid type polyurethane dispersion of 45 parts by weight, the calcium carbonate whisker of 10 parts by weight, 40 parts by weight self-dulling polyurethane resins, 0.20 parts by weight of ionic polyacrylate solution, 0.5 parts by weight of non-organic silicon and mineral oil Foaming agent, 8 parts by weight of polycarbodiimide curing agent, 0.08 parts by weight of associative polyurethane thickener, and 10 parts by weight of water.

[0077] Then the water-based anti-scratch coating solution is pumped into the intermediate tank through the liquid supply pump.

[0078] After the polyester film is longitudinally stretched by stretching equipment, the surface of the polyester film is subjected to corona treatment by corona equipment, and the strength of the corona machine is selected as 0.8KW. At the same time, the intermediate pump pumps the water-based coating liquid in the intermedi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com