Light-drive deformation-controllable composite and preparation method thereof

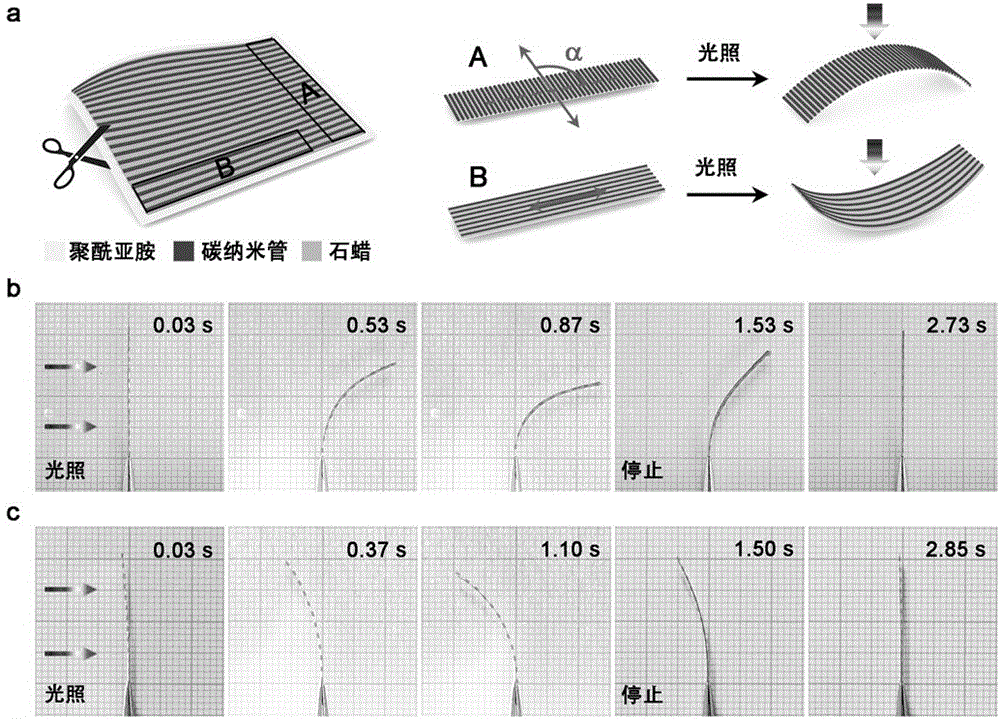

A composite material and composite layer technology, applied in the field of sensitive materials, can solve the problems of slow response deformation, single deformation form, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

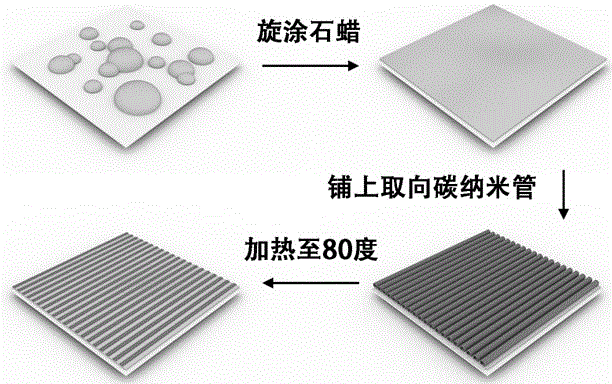

[0018] First, the preparation of paraffin / polyimide composite film

[0019] Fix the polyimide film on a glass plate with a flat surface, heat to 250°C and keep it for 2 hours, then cool to room temperature to keep the polyimide film isotropic. Then sprinkle the paraffin wax powder on the surface of the polyimide film, heat it to 60-100°C, and transfer it to a spin coater for spin coating while it is hot. When the spin coating speed is controlled at 300-3000 rpm, the density of the paraffin layer can be Controlled at 0.3-1.5mg / cm 2 , after cooling to room temperature, a paraffin / polyimide film was prepared.

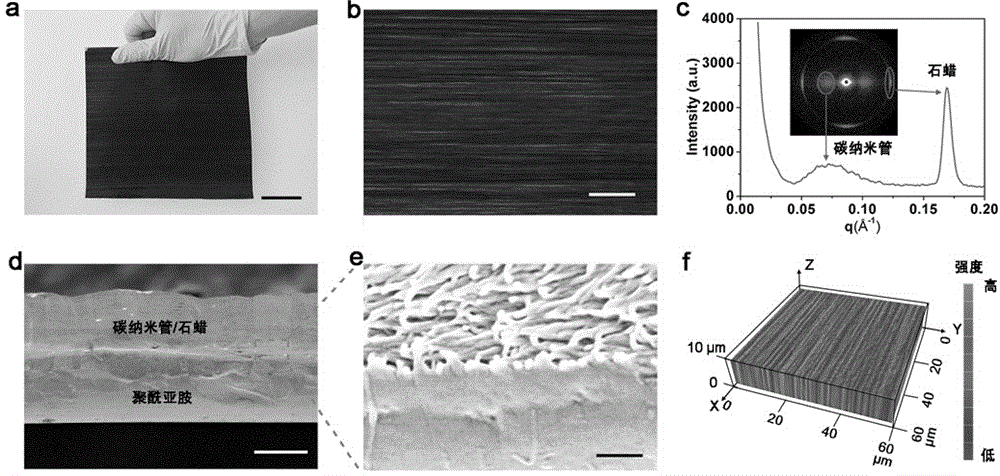

[0020] Second, the preparation of aligned carbon nanotubes / paraffin / polyimide films

[0021] The aligned carbon nanotube film is pulled out from the aligned carbon nanotube array, and spread on the surface layer of the paraffin / polyimide film with a thickness of 100-400nm. Then heat it to 60-100°C to melt the paraffin, and evenly enter the gap between the aligned carbon...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com