Inverted extrusion molding process of high pressure cylinder and inverted extrusion die adopted in inverted extrusion molding process

A forming process and reverse extrusion technology, applied in the direction of metal extrusion dies, etc., can solve the problems of difficult forming, high technical requirements, small diameter, etc., and achieve the effect of saving heating time, highly uniform inner diameter, and reliable use.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0036] Embodiment: A kind of high-pressure oil cylinder reverse extrusion forming process, its steps are as follows:

[0037] Step 1: Cut the material according to the size of the process;

[0038] Step 2: Heating: heat the billet at full power to 800°C and keep it warm for 90 minutes, then heat it at full power to 1180±10°C and keep it warm for 90 minutes;

[0039] Step 3: mold preheating: the mold is heated to 250-350°C;

[0040] Step 4: Pre-heading billet: Forge the heated billet on a 300MN hydraulic press to forge the flange, the pressure is controlled at 2500 tons, and the pressing speed is 20-30mm / s;

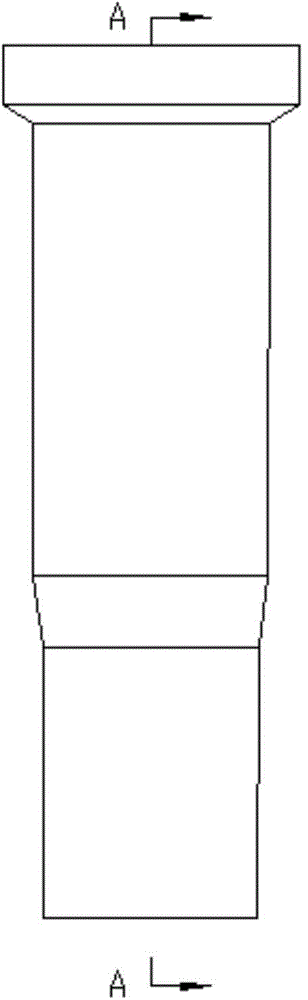

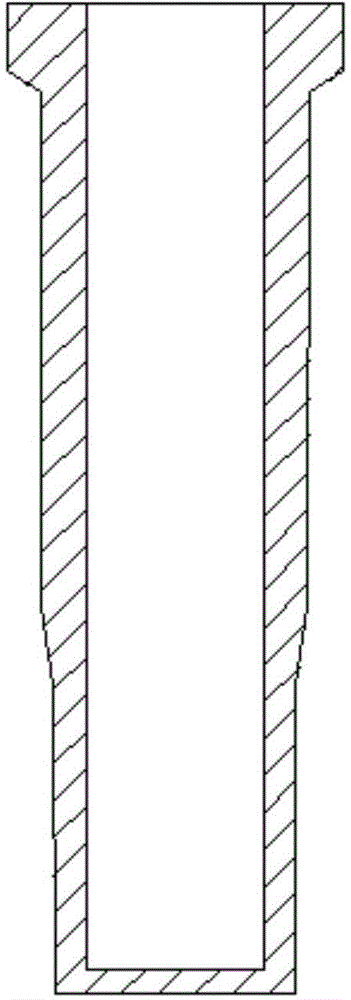

[0041] Step 5: Back-extruding on a 300MN hydraulic press: extruding the workpiece 10 through a step-by-step back-extrusion process;

[0042] Step 6: heat treatment (normalizing): heat the workpiece 10 in the heating furnace at full power to 910±10°C, keep it warm for 3.5 hours, and then take it out of the furnace and air cool it;

[0043] Step seven: take the sample;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com