Mesoporous molecular sieve/phosphoramide composite material and preparation method thereof

A technology of mesoporous molecular sieve and composite material, which is applied in the field of mesoporous molecular sieve/phosphoramide composite material and its preparation, can solve the problems of insufficient uranyl adsorption capacity and the like, and achieve excellent uranyl ion adsorption performance, high yield and good application. Foreground effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

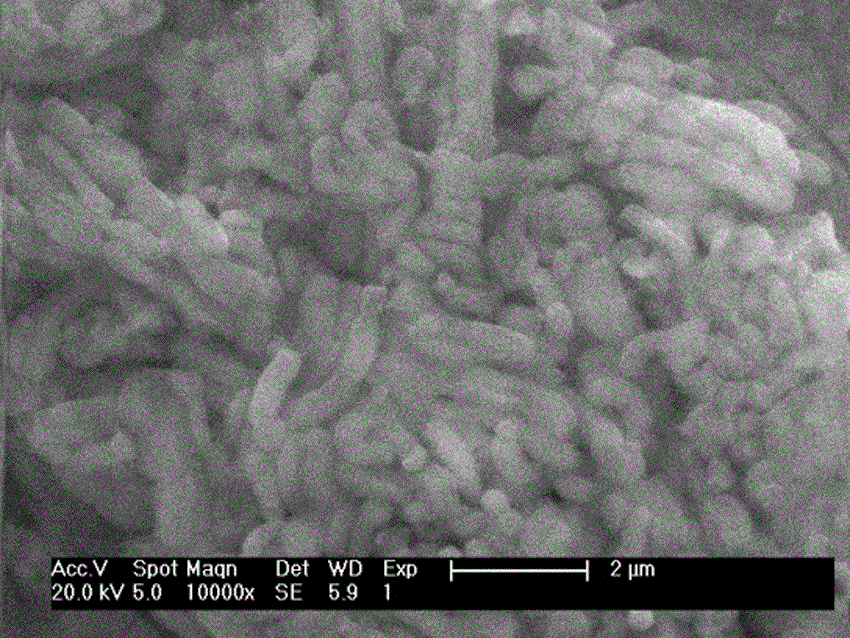

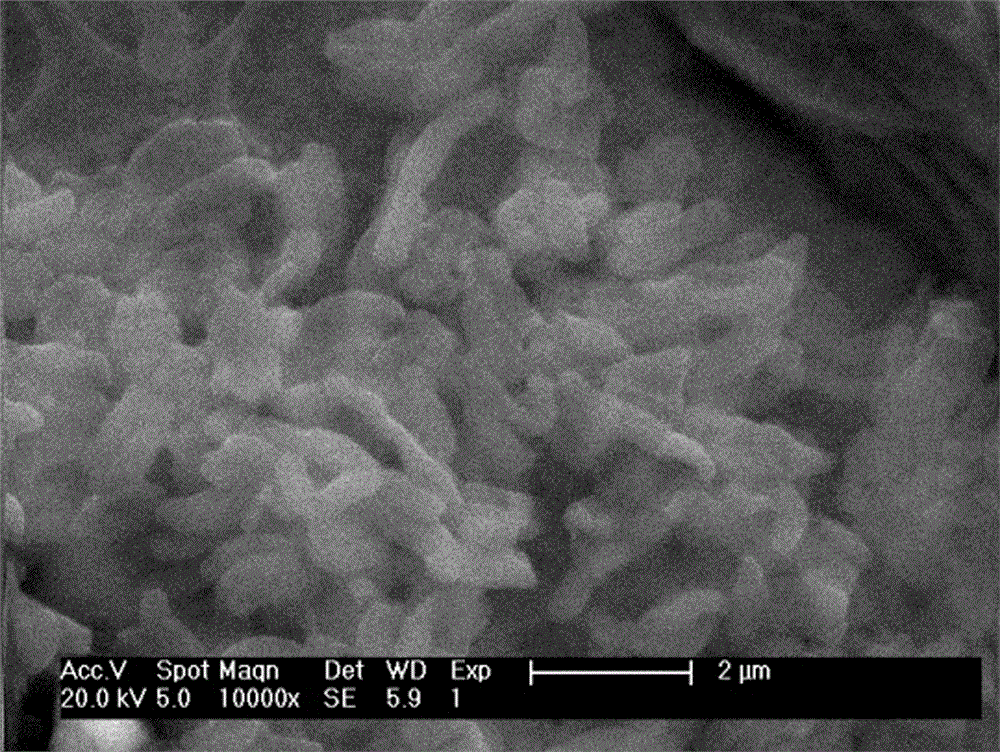

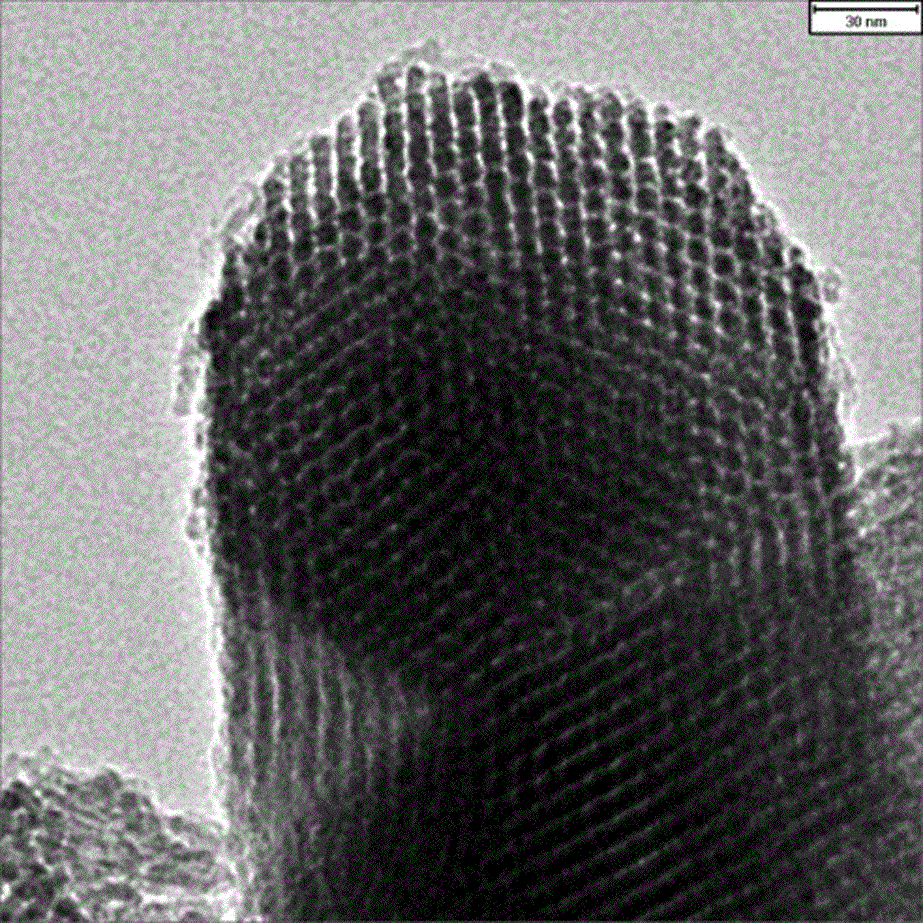

Image

Examples

Embodiment 1

[0046] Two mesoporous molecular sieve / phosphoramide composite materials with a grafting rate of 20% were prepared.

[0047] (1) Synthesis of phosphoramido silane coupling agent

[0048] Diethyl chlorophosphate (DECP) was used as the phosphorus source, 3-aminopropyltrimethoxysilane (APTMS) was used as the coupling agent, triethylamine (TEA) was used as the catalyst, and dried toluene was used as the solvent. Weigh DECP, APTMS and TEA according to the molar ratio of 3:1:0.2 and set aside. The weighed 0.1 mol 3-aminopropyltrimethoxysilane and 0.02 mol triethylamine were dissolved in 200 mL of dry toluene to obtain the first solution. The weighed 0.3 mol diethyl chlorophosphate was dissolved in 100 mL of dry toluene solution to obtain a second solution. Then, under the protection of nitrogen, add the first solution to the second solution in an ice water bath at 0~5℃, and stir vigorously while adding. After the addition, the reactant is warmed to room temperature and the reaction is c...

Embodiment 2

[0053] (1) Synthesis of phosphoramido silane coupling agent

[0054] Diethyl chlorophosphate (DECP) was used as the phosphorus source, 3-aminopropyltrimethoxysilane (APTMS) was used as the coupling agent, triethylamine (TEA) was used as the catalyst, and dried toluene was used as the solvent. Weigh DECP, APTMS and TEA according to the molar ratio of 1:1:1, and set aside. The weighed 0.1 mol 3-aminopropyltrimethoxysilane and 0.1 mol triethylamine were dissolved in 300 mL of dry toluene to obtain the first solution. The weighed 0.1 mol diethyl chlorophosphate was dissolved in 50 mL of dry toluene solution to obtain a second solution. Then, under the protection of nitrogen, add the first solution to the second solution in an ice-water bath at 0~5℃, and stir vigorously while adding. After the addition is completed, the reactant is warmed to room temperature and the reaction is continued for 8 hours to obtain the reaction product The reaction product is suction filtered to remove th...

Embodiment 3

[0058] (1) Synthesis of phosphoramido silane coupling agent

[0059] Diethyl chlorophosphate (DECP) was used as the phosphorus source, 3-aminopropyltrimethoxysilane (APTMS) was used as the coupling agent, triethylamine (TEA) was used as the catalyst, and dried toluene was used as the solvent. Weigh DECP, APTMS and TEA according to the molar ratio of 1:1:1, and set aside. The weighed 0.1 mol 3-aminopropyltrimethoxysilane and 0.1 mol triethylamine were dissolved in 300 mL of dry toluene to obtain the first solution. The weighed 0.1 mol diethyl chlorophosphate was dissolved in 50 mL of dry toluene solution to obtain a second solution. Then, under the protection of nitrogen, add the first solution to the second solution in an ice-water bath at 0~5℃, and stir vigorously while adding. After the addition is completed, the reactant is warmed to room temperature and the reaction is continued for 8 hours to obtain the reaction product The reaction product is suction filtered to remove th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com