Flexible epoxy resin composition

A technology of resin composition and epoxy resin, which is applied in the direction of epoxy resin glue, adhesive type, adhesive additive, etc., can solve the problems of low moisture resistance, poor peel strength, and decreased bonding strength, and achieve moisture resistance excellent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0149] Hereafter, although an Example demonstrates this invention more concretely, this invention is not limited to the following Example. In addition, "part" in the following description means "part by mass".

[0150] [Preparation of one-component thermosetting resin composition]

[0151] Each resin composition having the compounding composition shown in Table 1 was prepared. After measuring the specified amount of materials shown in Table 1 in a plastic container, use an autorotation-revolution vacuum mixer Awatori Kotaro (manufactured by Shinki Corporation, ARE-250) to fully mix at room temperature (25° C.) at 2000 rpm, and then remove Soak for 1 minute to obtain the target resin composition.

[0152] It should be noted that the details of the materials used are as follows,

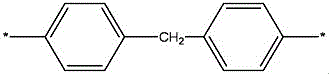

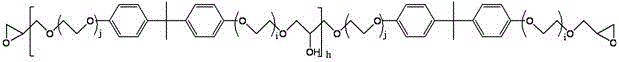

[0153] EXA4850-150: manufactured by DIC Corporation, vinyl ether modified bisphenol type epoxy resin) epoxy equivalent 450g / eq (equivalent to formula (1))

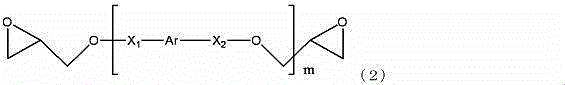

[0154] EXA4816: manufactured by DIC Corp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

| Epoxy equivalent | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com