Device utilizing waste plastics to thermally convert and prepare hydrogen-rich syngas and process

A technology for waste plastics and synthesis gas, which is applied in gasification process, manufacture of combustible gas, petroleum industry, etc., can solve the problems of human harm, low utilization rate of waste plastics, secondary pollution, etc., and achieves accelerated pyrolysis conversion rate, The effect of optimizing energy utilization and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

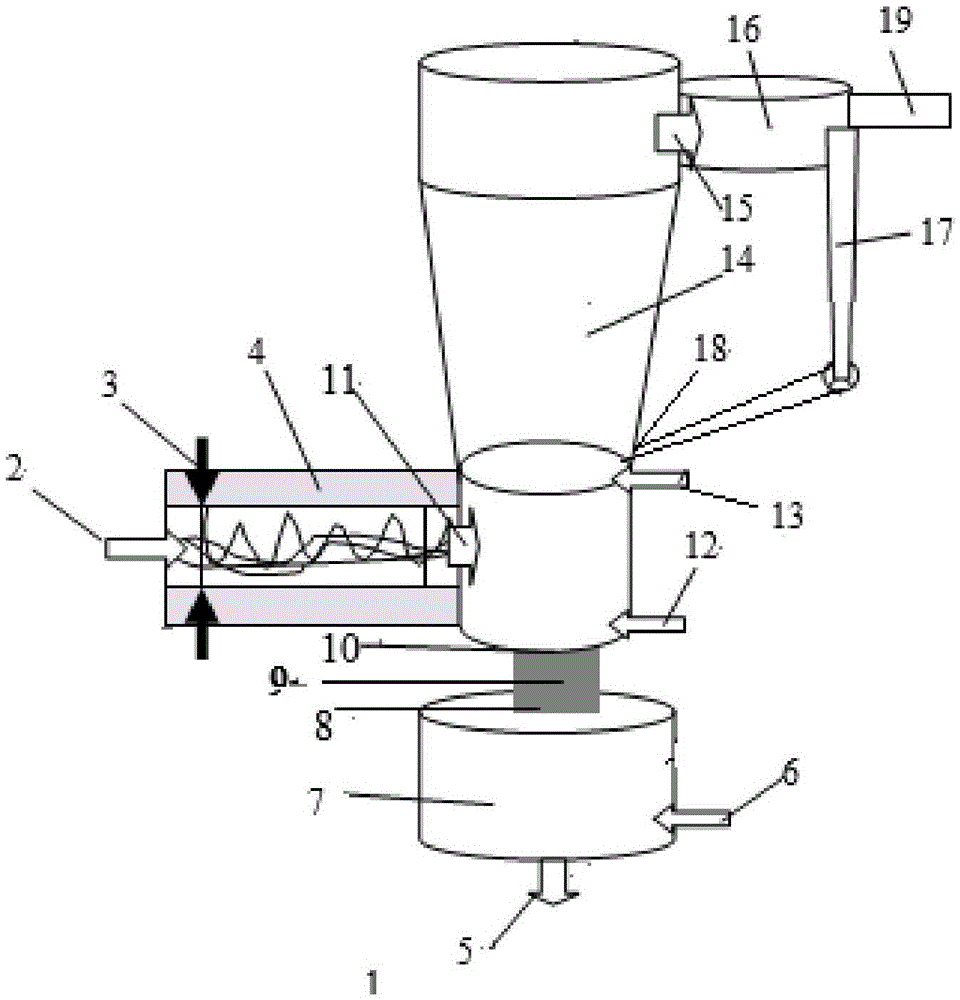

Method used

Image

Examples

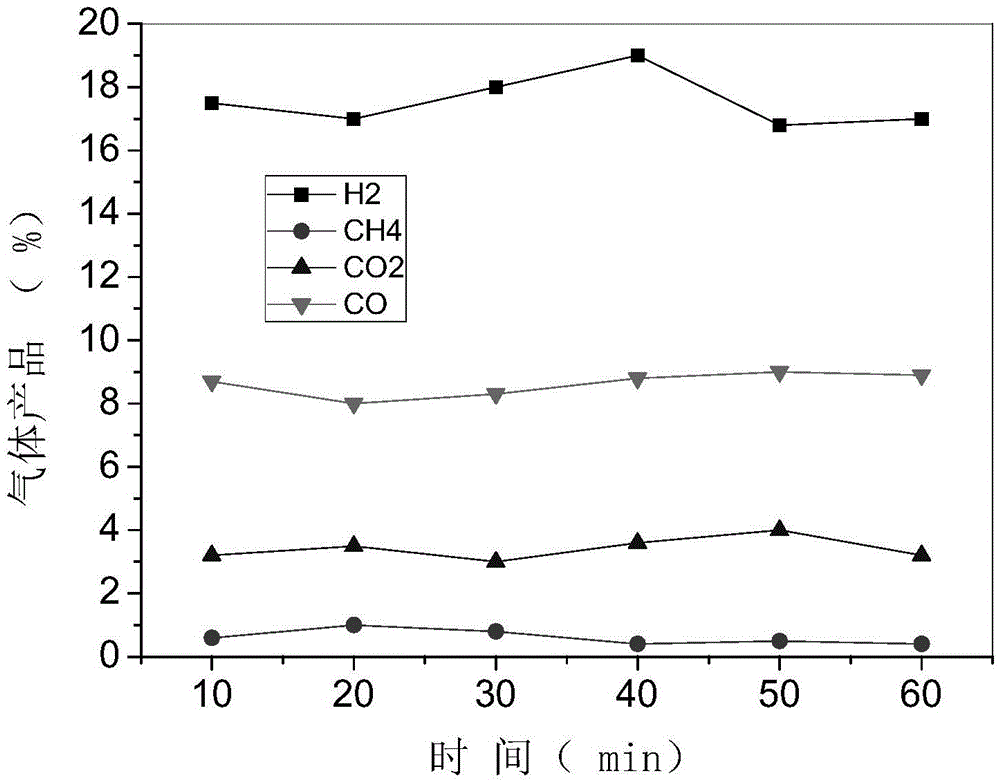

Embodiment 1

[0050] Feed waste plastics into the device at a feed rate of 10kg / h, and control the temperature inside the horizontal tubular pyrolysis furnace 4 to 500°C under the action of water vapor and external heating for pyrolysis, and the pyrolysis part of the horizontal tubular pyrolysis furnace 4 The molar ratio of water vapor to carbon in waste plastics is H 2 O:C=1:1, the molar ratio H of the water vapor in the gasification part gasification furnace 14 to the carbon in the waste plastics 2 O:C=3:1, the molar ratio of calcium in the calcium oxide particles in the gasification furnace 14 to carbon in the waste plastics Ca:C=1.2:1, the gasification temperature is controlled at 600°C, and the particle size of the calcium oxide particles is 0.40 mm, the molar number of carbon and oxygen in the air in the pyrolysis solid residue entering the melting part C:O=1:1, the temperature in the molten pool is controlled at 1500°C, the system operates continuously for 1 hour, and the gas composi...

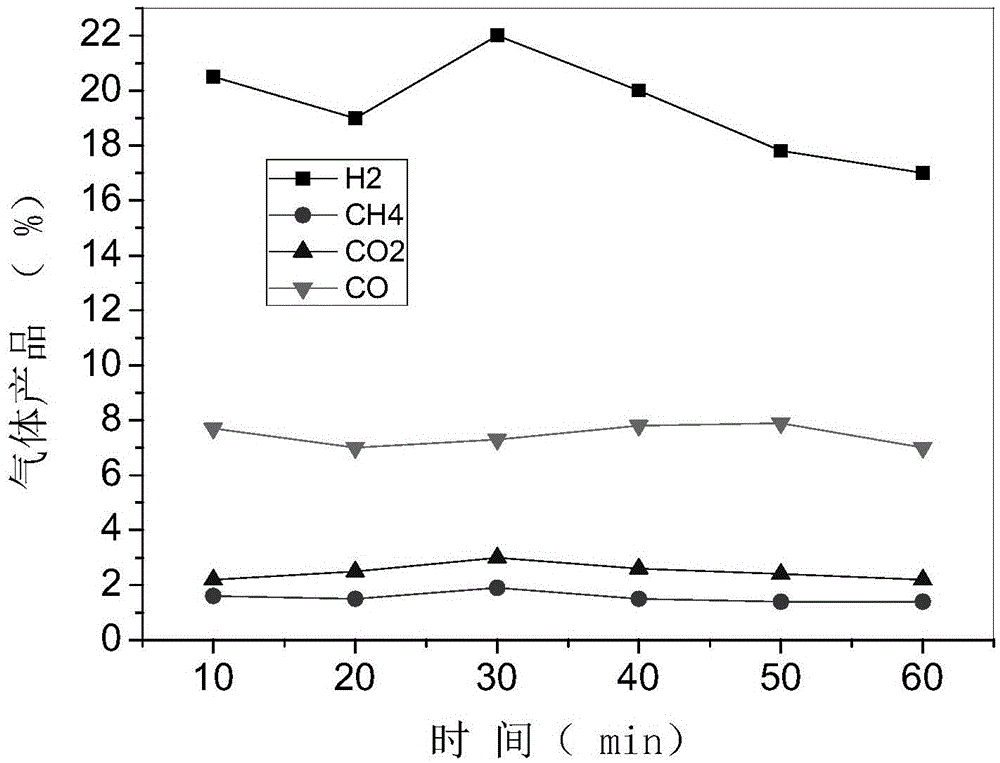

Embodiment 2

[0052] Feed waste plastics into the device at a feed rate of 20kg / h, and control the temperature of the pyrolysis furnace to 400°C under the action of water vapor and external heating for pyrolysis. The molar ratio of carbon in the plastic is H 2 O:C=1:2, the molar ratio H of water vapor in the gasification partial gasification furnace 14 and carbon in waste plastics 2 O:C=5:1, the amount of calcium oxide to be sprayed is based on the molar ratio of calcium to carbon in waste plastics Ca:C is 1.5:1, the gasification temperature is controlled at 550°C, and the particle size of calcium oxide particles is 0.50mm. The molar number of carbon and oxygen in the air in the pyrolysis solid residue entering the melting part is C:O=1:1, the temperature in the molten pool is controlled at 1400°C, the system is continuously operated for 1 hour, and the gas composition of the product is analyzed by GC. The result is as image 3 As shown, the calculated average volume concentration of the ...

Embodiment 3

[0054] Feed waste plastics into the device at a feed rate of 30kg / h, and control the temperature inside the horizontal tubular pyrolysis furnace 4 to 550°C under the action of water vapor and external heating for pyrolysis, and the pyrolysis part of the horizontal tubular pyrolysis furnace 4 The molar ratio of water vapor to carbon in waste plastics is H 2 O:C=1:1.5, the molar ratio H of the water vapor in the gasification part gasification furnace 14 to the carbon in the waste plastics 2 O:C=3:1, the amount of calcium oxide sprayed is based on the molar ratio of calcium to carbon in waste plastics Ca:C is 1.2:1, the gasification temperature is controlled at 600°C, and the particle size of calcium oxide particles is 0.50mm. The molar number of carbon and oxygen in the air in the pyrolysis solid residue entering the melting part is C:O=1:1, the temperature in the molten pool is controlled at 1600°C, the system is continuously operated for 1 hour, and the gas composition of the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal decomposition temperature | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com