Device and method for ultrasonic vibration assisted electrical discharge grinding

A technology of ultrasonic vibration and auxiliary discharge, which is applied in the field of precision parts manufacturing of conductive hard and brittle materials, can solve the problems of no-load pulse, short-circuit pulse, chip accumulation, etc. The effect of the processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and examples, but the protection scope of the present invention is not limited to the range indicated by the examples.

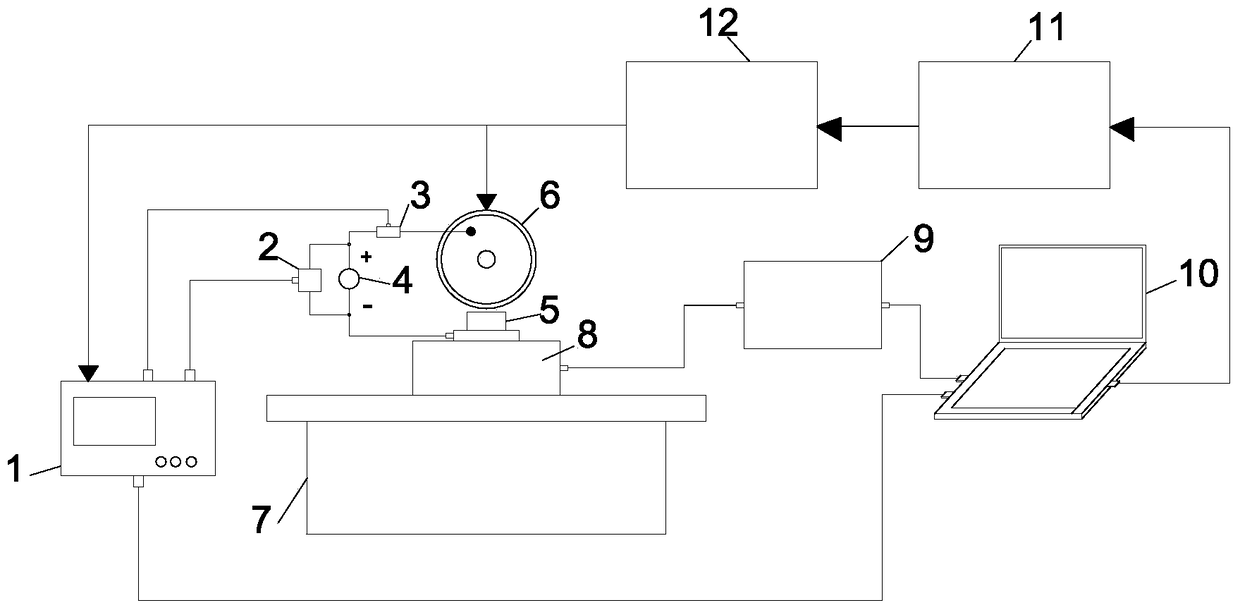

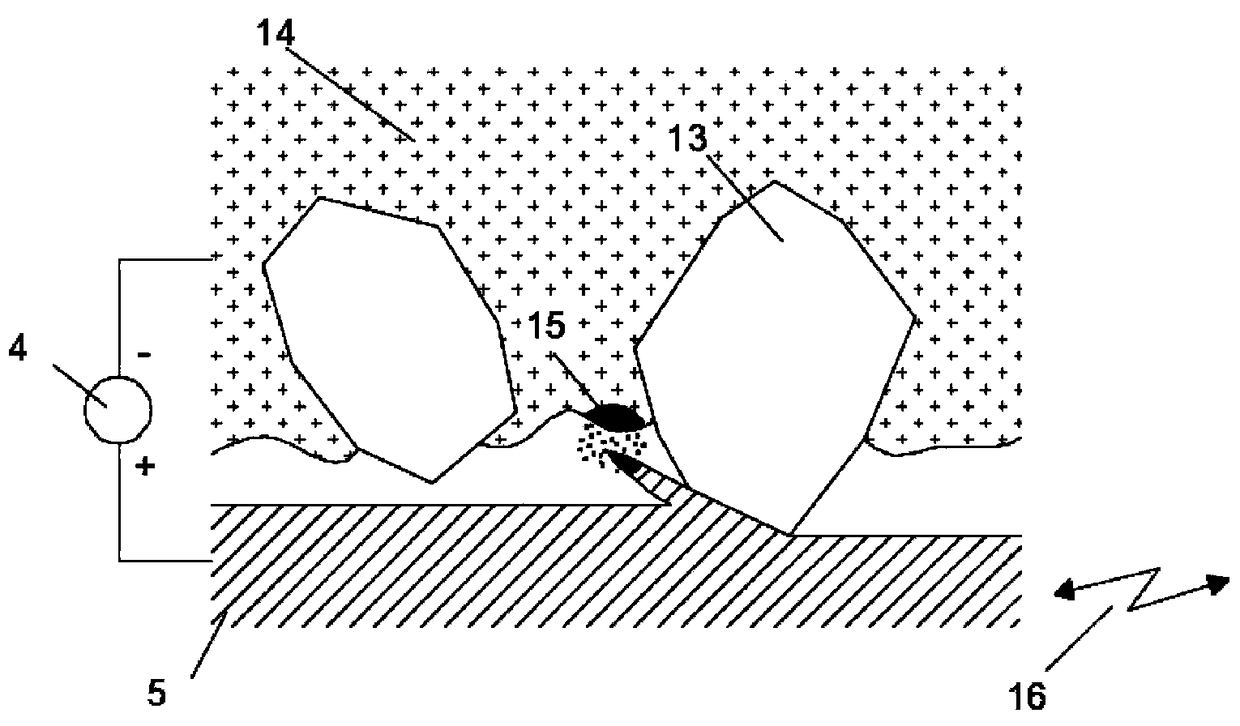

[0038] like figure 1 As shown, an ultrasonic vibration-assisted electric discharge grinding processing device includes an ultra-precision grinding machine 7 equipped with a diamond grinding wheel 6, a pulse power supply 4, and also includes:

[0039] A pulse discharge parameter acquisition system for real-time acquisition of pulse discharge parameters during diamond grinding wheel 6 processing;

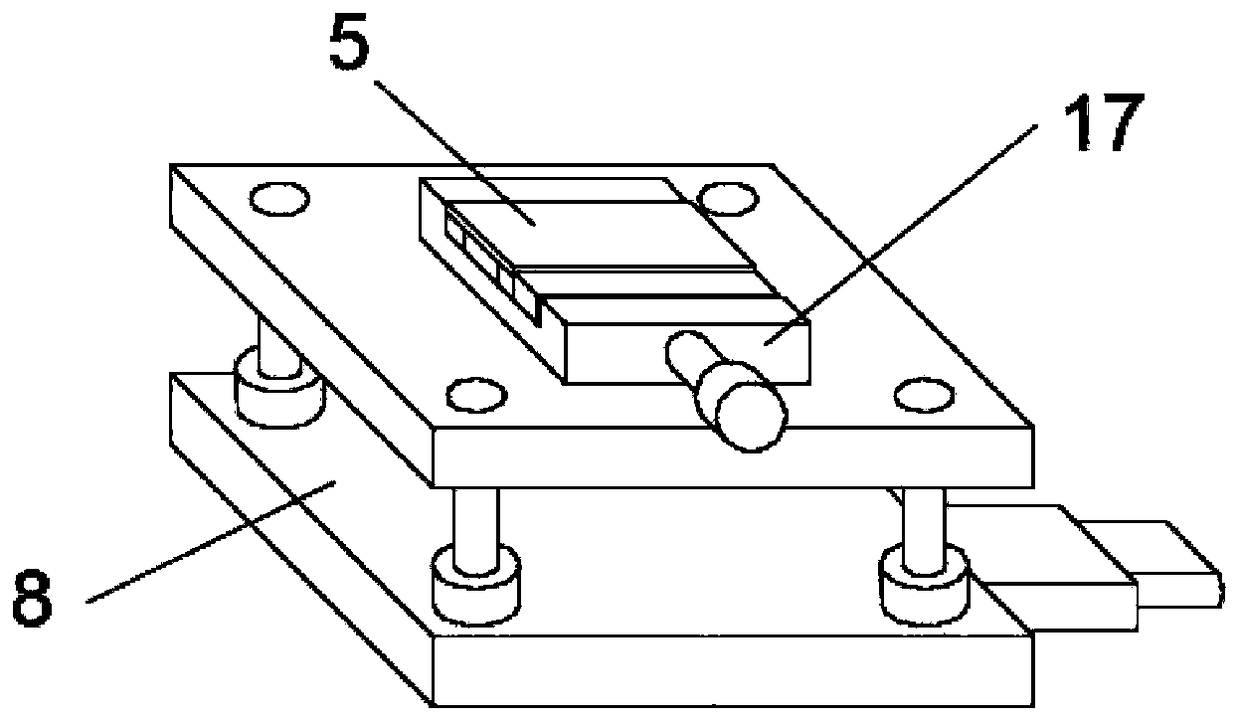

[0040] The ultrasonic vibration auxiliary device is fixed on the workbench of the ultra-precision grinding machine 7, and is used for installing the conductive workpiece 5 and causing the workpiece 5 to generate axial ultrasonic vibration;

[0041]The data processing and adjustment system is used to analyze ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com