Preparation method and application of heterojunction photocatalyst

A photocatalyst and heterojunction technology, applied in chemical instruments and methods, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc., can solve the problem of limited solar energy utilization, low photocatalytic activity, The degradation effect is not high, and the effect of excellent photocatalytic activity, simple process operation and low cost is achieved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

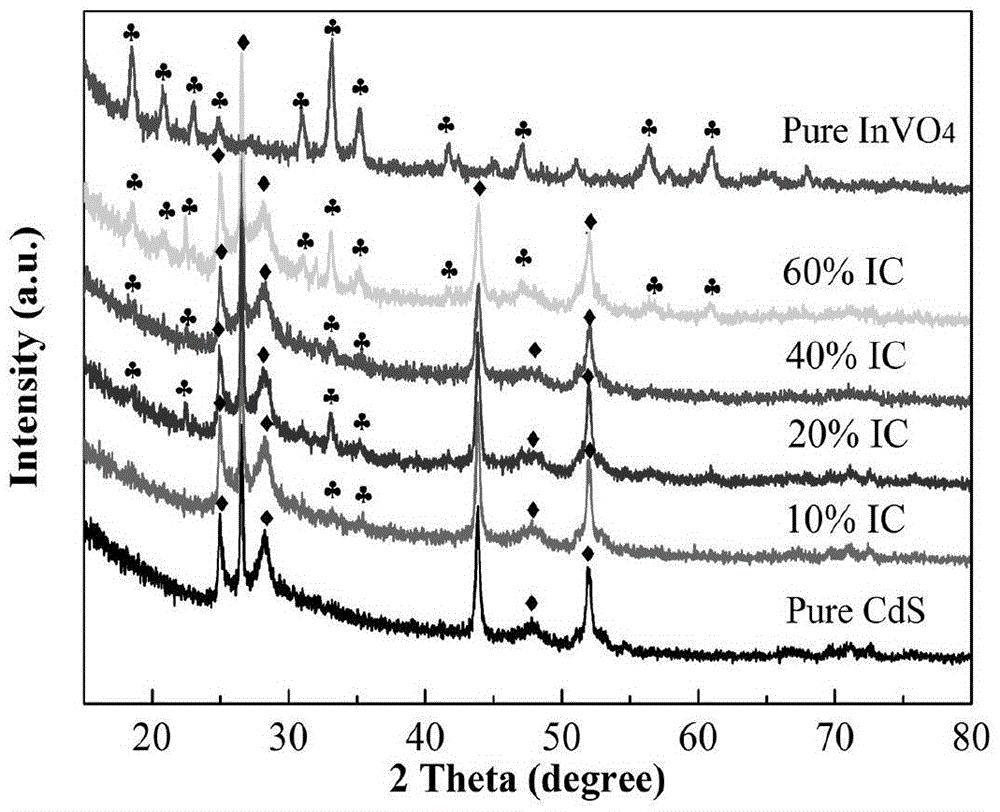

[0028] Step (1): Weigh 1mmol indium nitrate (0.382g) and 1mmol ammonium metavanadate (0.117g) and dissolve them in 100mL pure water, heat and dissolve to obtain a yellow precursor suspension, then transfer to a 250mL three-necked flask, microwave React at 800W, 100°C, 5h, and finally wash with water, filter and dry to obtain indium vanadate A. Step (2): Weigh 1mmol of cadmium acetate (0.266g) and 2mmol of thiourea (0.076g) and dissolve them in 40mL of pure water, ultrasonically disperse to obtain a transparent solution, then transfer to a 50mL hydrothermal kettle, and conduct a hydrothermal reaction at 160°C , 24h, finally washed with water, filtered and dried to obtain cadmium sulfide B.

[0029] Step (3): Dissolve 0.015g of indium vanadate A, 1mmol of cadmium acetate (0.266g) and 2mmol of thiourea (0.076g) in 40mL of pure water, and ultrasonically disperse to obtain a light yellow precursor suspension, which is then transferred to 50mL In a hydrothermal kettle, the hydrothe...

Embodiment 2

[0031] Step (1): Weigh 1mmol indium nitrate (0.382g) and 1mmol ammonium metavanadate (0.117g) and dissolve them in 100mL pure water, heat and dissolve to obtain a yellow precursor suspension, then transfer to a three-necked flask, microwave reaction 800W , 100°C, 5h, finally washed with water, filtered and dried to obtain indium vanadate A.

[0032] Step (2): Weigh 1mmol of cadmium acetate (0.266g) and 2mmol of thiourea (0.076g) and dissolve them in 40mL of pure water, ultrasonically disperse to obtain a transparent solution, then transfer to a 50mL hydrothermal kettle, and conduct a hydrothermal reaction at 160°C , 24h, finally washed with water, filtered and dried to obtain cadmium sulfide B.

[0033] Step (3): Dissolve 0.030g of indium vanadate A, 1mmol of cadmium acetate (0.266g) and 2mmol of thiourea (0.076g) in 40mL of pure water, ultrasonically disperse to obtain a light yellow precursor suspension, and then transfer to 50mL In a hydrothermal kettle, the hydrothermal rea...

Embodiment 3

[0035] Step (1): Weigh 1mmol indium nitrate (0.382g) and 1mmol ammonium metavanadate (0.117g) in 100mL pure water, heat and dissolve to obtain a yellow precursor suspension, then transfer to a three-necked flask, microwave reaction 800W, 100 ℃, 5h, and finally washed with water, filtered and dried to obtain indium vanadate A.

[0036] Step (2): Weigh 1mmol of cadmium acetate (0.266g) and 2mmol of thiourea (0.076g) and dissolve them in 40mL of pure water, ultrasonically disperse to obtain a transparent solution, then transfer to a 50mL hydrothermal kettle, and conduct a hydrothermal reaction at 160°C , 24h, finally washed with water, filtered and dried to obtain cadmium sulfide B.

[0037] Step (3): Dissolve 0.060g of indium vanadate A, 1mmol of cadmium acetate (0.266g) and 2mmol of thiourea (0.076g) in 40mL of pure water, and ultrasonically disperse to obtain a pale yellow precursor suspension, which is then transferred to 50mL In a hydrothermal kettle, the hydrothermal react...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com