Formaldehyde synthesis catalyst by iron molybdenum method and preparation method thereof

A catalyst, iron-molybdenum technology, applied in the field of iron-molybdenum catalyst and its preparation, can solve the problem that the formaldehyde yield of the catalyst is less than 92%, and achieve the effects of long service life, good mass and heat transfer, and good thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

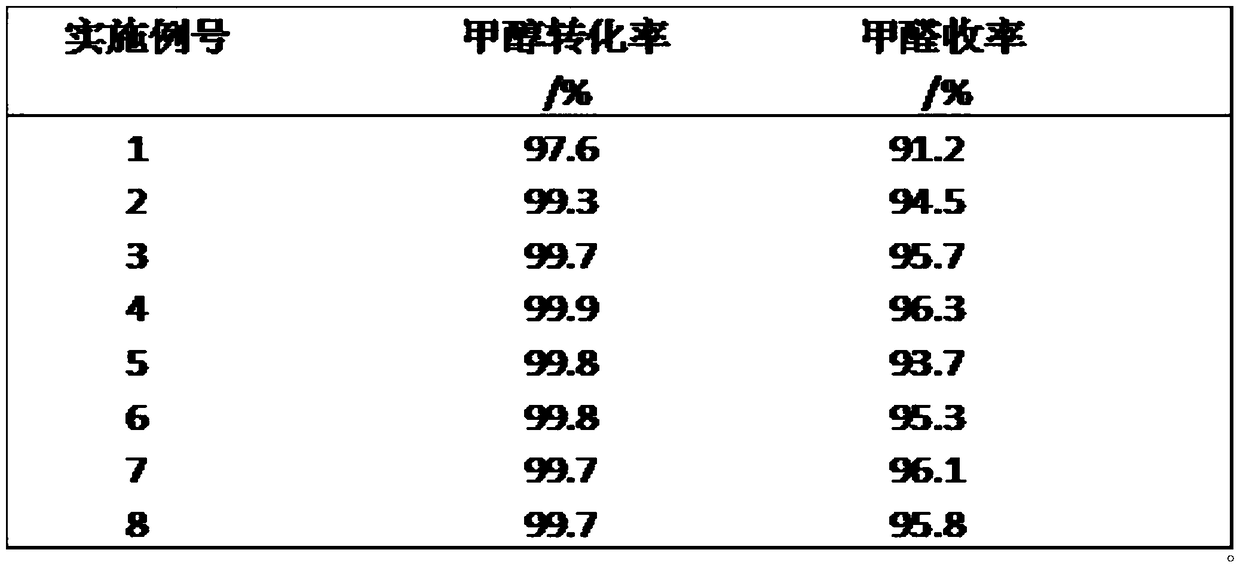

Examples

Embodiment 1

[0014] Be that precipitation temperature is 65 ℃, under strong stirring, in 2660ml, mass concentration is 15% ammonium molybdate solution, add 1000ml mass concentration rapidly in 3 minutes and be 10% ferric nitrate solution, remaining 2500ml mass concentration is 10 % ferric nitrate solution was slowly added in the ammonium molybdate solution in 20 minutes, when the pH value of the co-precipitation reaction suspension was 1.8, the pH value required for the reaction was adjusted to the end of the reaction with ammonia water, after the precipitation reaction ended , continue to stir for 1.0 hours, settle and remove the supernatant, wash twice, filter, dry the filter cake at 110 ° C, add 6% of the weight of the dry filter cake, kneading, extruded into ¢1.5mm× 4.5mm, length of 4.5mm hollow cylinder, after drying, within 18 hours, use the temperature program to increase the calcination temperature from room temperature to 420 ℃, and keep it at this temperature for 2 hours, the cata...

Embodiment 2

[0016] It is 65 ℃ at precipitation temperature, under strong stirring, in 2660ml, mass concentration is in the ammonium molybdate solution of 15%, in the time of 3 minutes, add 1000ml mass concentration rapidly and be 10% ferric nitrate and nickel nitrate mixed solution (nickel occupies 0.5% of the catalyst mass), the remaining 2500ml mixed acid solution was slowly added to the ammonium molybdate solution in 20 minutes, when the pH value of the co-precipitation reaction suspension was 1.8, the pH value was adjusted to the end of the reaction with ammonia water, and continued Stir for 1.0 hour, settle and remove the supernatant, wash twice, filter, dry the filter cake at 110°C, add 6% of the weight of the dry filter cake of methylcyanine powder, knead with water, extrude into ¢4.5×2.0mm, A hollow cylinder with a length of 4.5 mm. After drying, within 18 hours, use a temperature program to raise the roasting temperature from room temperature to 420 ° C, and keep it at this temper...

Embodiment 3

[0018] Be 65 ℃ at precipitation temperature, under strong stirring, in the ammonium molybdate solution that 2660ml, mass concentration are 15%, add 1500ml mass concentration rapidly in 5 minutes and be that 10% ferric nitrate and nickel nitrate mixed solution (nickel occupies 1.5% of the catalyst mass), the remaining 2000ml mixed acid solution was slowly added to the ammonium molybdate solution in 20 minutes, when the pH value of the co-precipitation reaction suspension was 1.8, the pH value was adjusted to the end of the reaction with ammonia water, and continued Stir for 1.0 hour, settle and remove the supernatant, wash twice with deionized water, filter, dry the filter cake at 110°C, add 6% of the weight of the dry filter cake of scallop powder and methyl cellulose, add water and knead, Extruded into a hollow cylinder with a length of ¢4.5×2.0mm and a length of 4.5mm. After drying, within 18 hours, use a temperature program to raise the roasting temperature from room tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com