Preparation method of copper ion adsorbent based on metal-organic framework material

A metal-organic framework and copper ion technology, applied in chemical instruments and methods, adsorption water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of long time and low adsorption capacity of adsorbents, and achieve adsorption efficiency High and significant adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Example 1 Preparation method of copper ion adsorbent based on metal organic framework material

[0027] (1) Pyrrole and methyl p-formylbenzoate were dissolved in propionic acid, the solution was refluxed for 12 h under dark room conditions, and the reaction mixture was cooled to room temperature. The product was dissolved in a mixed solution of tetrahydrofuran and methanol, added KOH solution, mixed and stirred for 12 hours, cooled to room temperature, evaporated tetrahydrofuran and methanol, added water until the solid was completely dissolved, added hydrochloric acid solution until no precipitation was formed, washed with water, and dried.

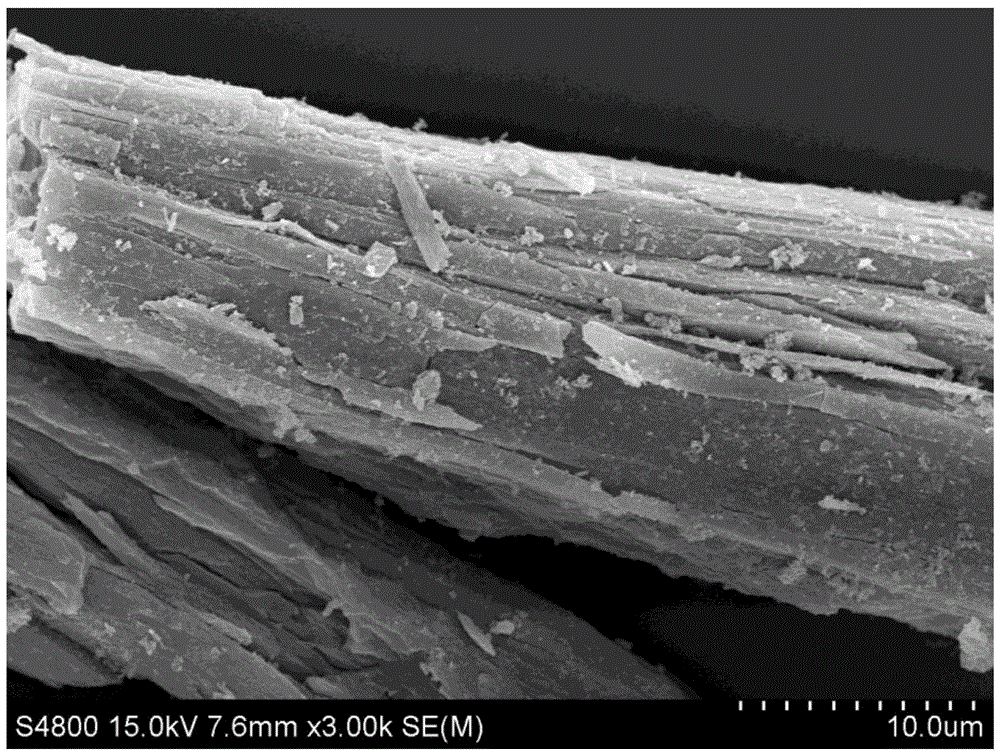

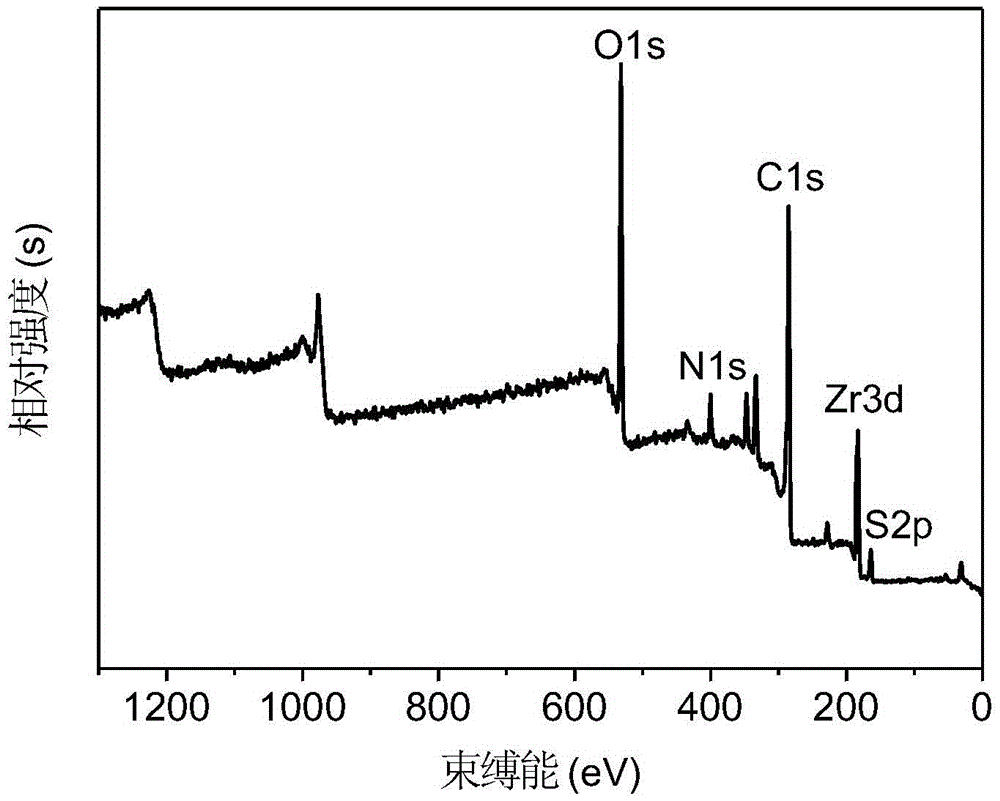

[0028] (2) Dissolve zirconium oxychloride in DMF and sonicate, add the product obtained in step (1) and sonicate for 10 minutes, add benzoic acid and transfer to a polytetrafluoroethylene-lined reaction kettle at 130° C. for 72 hours. After the reactant was cooled to room temperature, it was washed successively with DMF and aceton...

Embodiment 2

[0031] Embodiment 2 test result measurement

[0032] The mercapto-functionalized MOF adsorbent prepared in Example 1 was subjected to a copper adsorption test. Take 100mL of wastewater into a beaker, add 10mg of wastewater adsorbent to the wastewater, use NaOH or HNO 3 Adjust the pH of the solution to 5, shake and absorb at room temperature for 15 minutes, take the supernatant, and detect the remaining copper ion concentration in the supernatant by flame atomic absorption spectrometry. The removal rate of heavy metal ions w=(initial concentration-concentration after adsorption) / initial concentration, and the test results are shown in Table 1.

[0033] Table 1

[0034]

Initial concentration (mg / L)

Concentration after adsorption (mg / L)

sample 1

10

5.84

sample 2

9.0

4.90

sample 3

8.0

3.73

Sample 4

7.0

2.74

Sample 5

6.0

1.8

[0035] It can be seen from Table 1 that the wastewat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com