Artificial liver cell microfluidic microcapsule preparation method and microfluidic microcapsule generating device

A generating device and microfluidic technology, which is applied in the field of tissue engineering and laboratory equipment, can solve the problems of inability to maintain functions for a long time, achieve the effects of maintaining seed cell functions, facilitating oil-water separation and harvesting, and simplifying equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

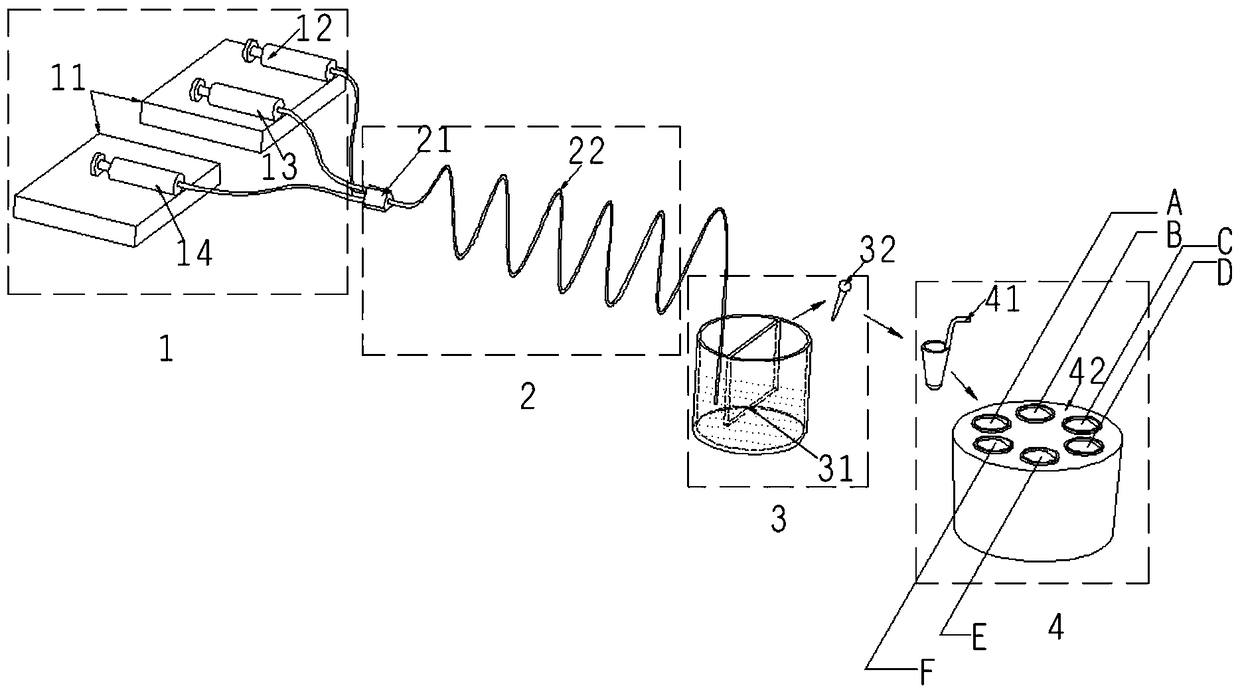

[0064] Embodiment 1: A kind of microfluidic microcapsule generating device of the present invention

[0065] A microfluidic microcapsule generating device, such as figure 1 , figure 2 As shown, it includes a sample loading pusher component 1, a capsule forming component 2, and a separation membrane forming component 3;

[0066] The sample loading propulsion assembly includes a micropump pump 11 and three syringes 12, 13, 14;

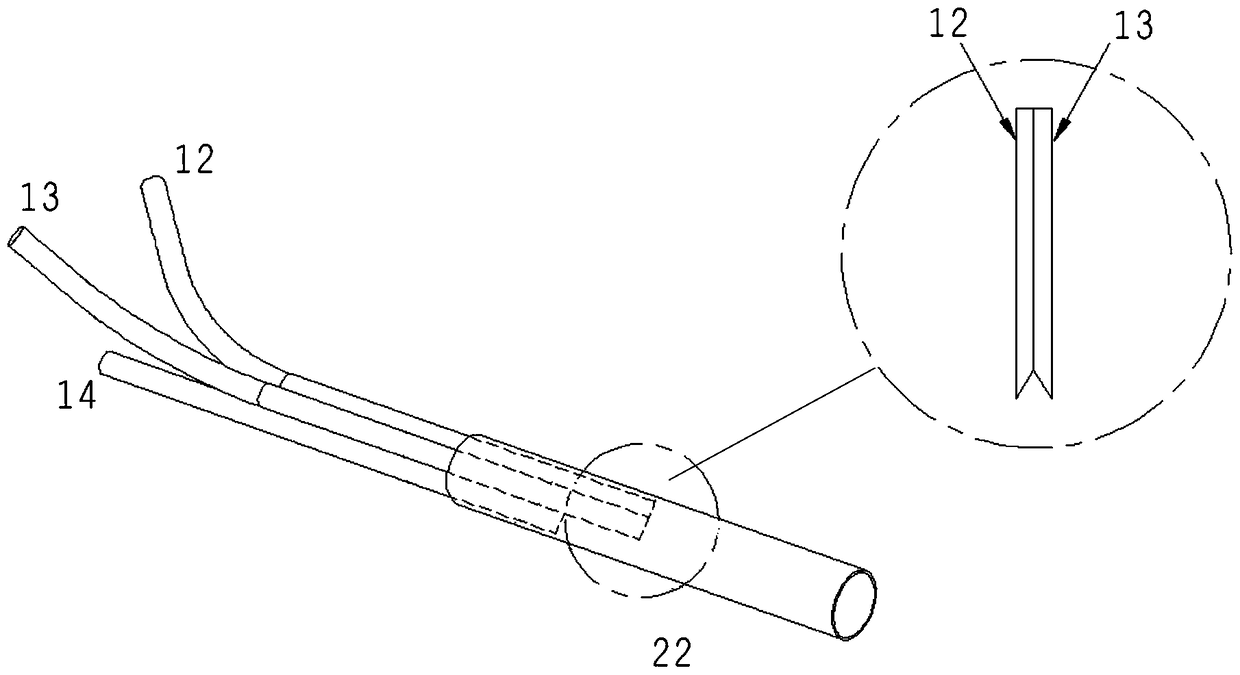

[0067] The encapsulation component is a continuous microfluidic channel; the front end is a microfluidic channel access end 21, with a built-in continuous phase channel and two dispersed phase channels; the rear end is a hollow corrugated microfluidic channel 22;

[0068] The separation and film formation assembly includes an oil-water separator 3 and a rotary film formation platform 4 in sequence; the rotary film formation platform is composed of a turntable 42 and at least six collecting pipes.

[0069] Described a continuous phase channel is conne...

Embodiment 2

[0072] Example 2: Preparation and culture of microencapsulated liver cancer cells HepG2

[0073] The cell material used in this example is liver cancer cell HepG2 (HepG2 cells were purchased from the Institute of Cells, Chinese Academy of Sciences). After digestion and centrifugation, the HepG2 cells were mixed with 1.8% sodium alginate mixed solution, and the final concentration was 5×10 6 pcs / ml, load it into figure 1 13 in the 10ml syringe shown. Add 1.1% calcium chloride solution equal to the volume of the syringe 13 in the syringe 12, and inject the soybean oil into the syringe 14.

[0074] Micro injection pump 11 can control the sample loading speed of all syringes. Preferably, syringes 12 and 13 are injected at a speed of 100ul / min (equipped with a common micro injection pump), and syringe 14 is injected at a rate of 55ml / h. Speed bolus injection (a single microbolus injection pump).

[0075] The dispersed phase and the continuous phase solution form microcapsules ...

Embodiment 3

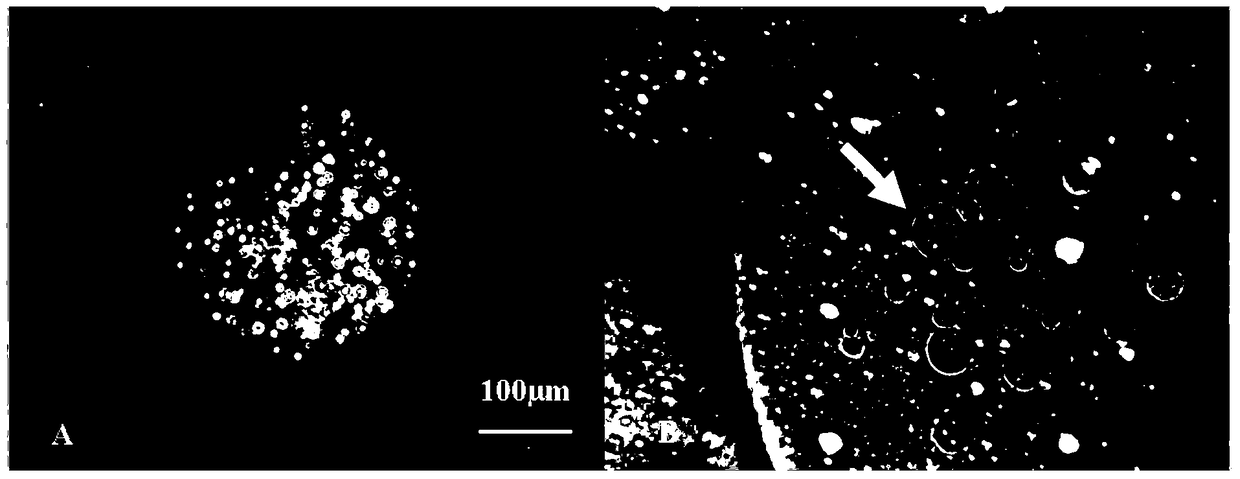

[0078] Example 3: Detection of mechanical strength of microcapsules before and after improvement of microcapsule components

[0079] In this example, the microcapsule damage rate (the ratio of the number of damaged microcapsules to the total number of microcapsules) was used as an index to investigate the mechanical strength of the microcapsules.

[0080] The HepG2 cells were fully mixed with 1.8% sodium alginate solution (before improvement group) and 1.8% sodium alginate mixed solution (after improvement group) respectively, and microcapsules were made respectively according to Example 2. The microcapsules were suspended in DMEM complete medium, and the number of microcapsules in the medium was adjusted to 100 / ml. Take 50ml of the freshly prepared above-mentioned suspension and place it in a 100ml beaker, stir on a magnetic stirrer at low, medium, and high speeds for 1 min, then randomly count the number of damaged microcapsules in 100 microcapsules under a microscope, and r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com