Automatic solder-free welding technology for precious metal ornaments

A welding technology and precious metal technology, applied in clothing, applications, jewelry, etc., can solve problems such as affecting the appearance of products and poor welding effect, and achieve the effects of beautiful products, easy control of welding process, and good welding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

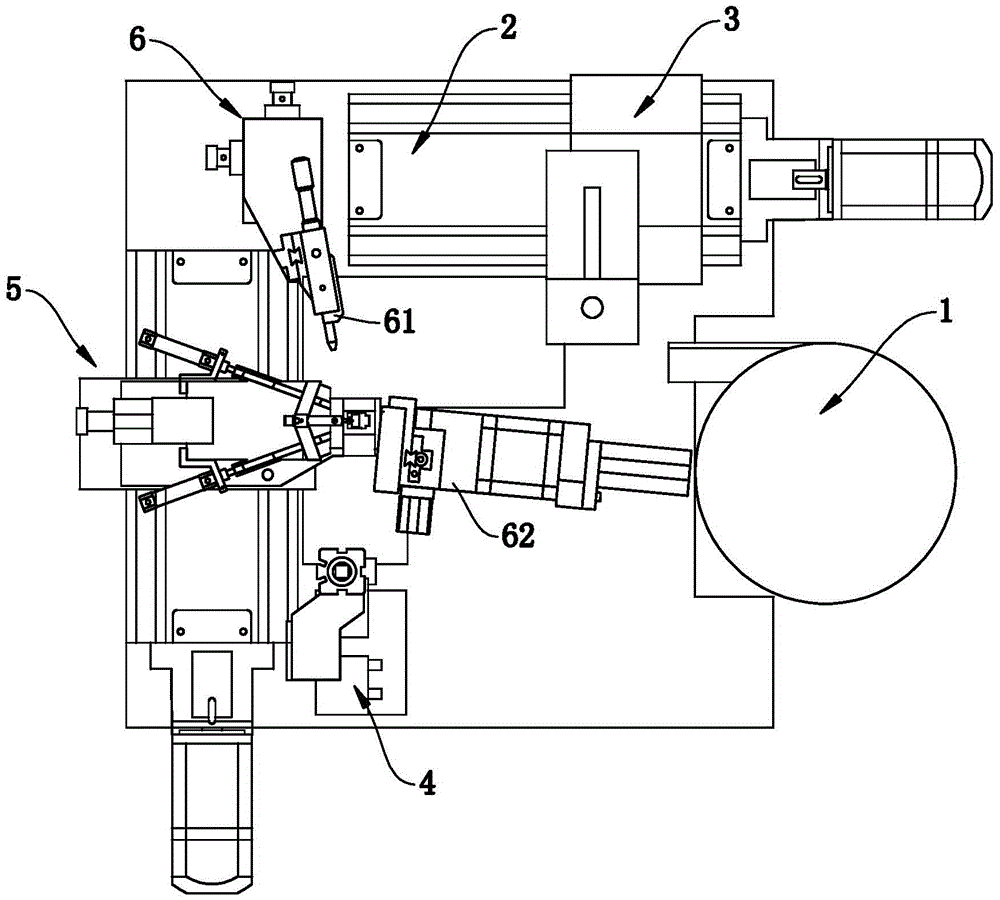

[0026] Such as figure 1 As shown in the figure, an automatic solderless welding technology for precious metal jewelry, including chain link production equipment with lifting lugs at both ends, the chain link production equipment includes a bead feeding device 1, a bead clamping device 2, a steering mechanism 3, and a wire feeding device 4 , a bending device 5 and a welding device 6, the welding device 6 includes a first welding torch 61 and a second welding torch 62, and the chain ring production equipment is a chain ring with hanging lugs at both ends disclosed in the Chinese invention patent application CN104015059A Equipment, no more details here; include the following steps:

[0027] (1) The bead feeding device 1 conveys the chain beads to the bead clamping device 2. The bead clamping device 2 clamps the chain beads, and then sends one end of the chain beads to the forming position. At the same time, the wire feeding device 4 conveys the material line and cuts off the fini...

Embodiment 2

[0039] This embodiment is basically the same as Embodiment 1, the difference is that the material of the chain beads and lifting lugs are all silver, during the welding process, the pressure of the first welding torch 61 and the second welding torch 62 is 1.4Mpa, and the preheating time is 1s, since the melting point of silver is 961°C, during the welding process, the flame temperature of the first welding torch 61 and the second welding torch 62 is 900°C-1000°C, preferably 1000°C in this embodiment.

Embodiment 3

[0041] This embodiment is basically the same as Embodiment 1, the difference is that the material of the chain beads and lifting lugs are all platinum, during the welding process, the pressure of the first welding gun 61 and the second welding gun 62 is 1Mpa, and the preheating time is 5s Since the melting point of platinum is 1769° C., the flame temperature of the first welding torch 61 and the second welding torch 62 is 1700° C. to 1800° C., preferably 1800° C. in this embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com