Sugar solution production method

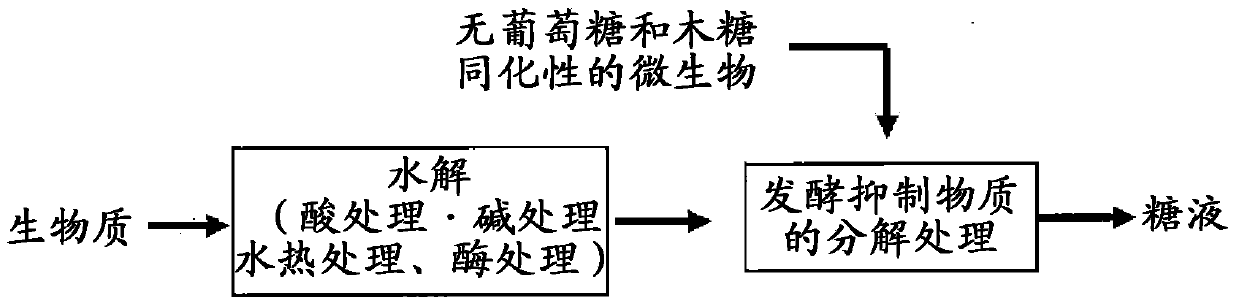

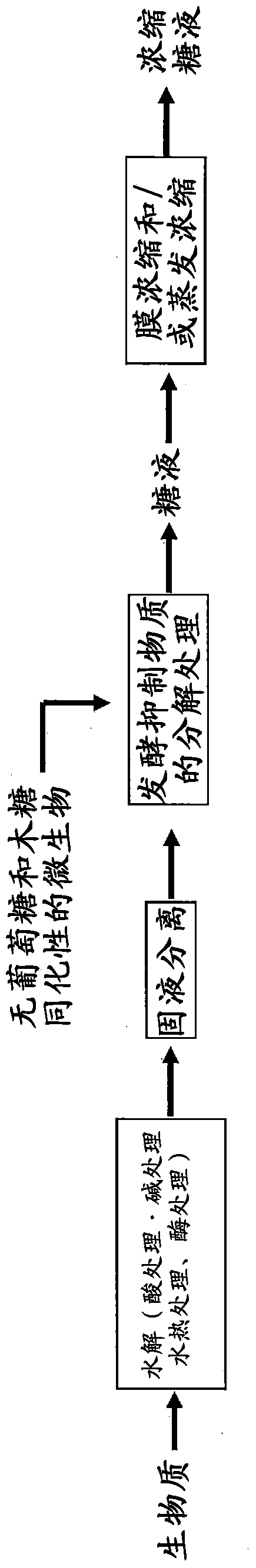

A manufacturing method and sugar solution technology, which can be applied to methods using microorganisms, sugar production, and sugar solution boiling/evaporation, etc., and can solve the problems of cost, input of a large amount of energy, and low removal efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0109] Examples are given below to describe the present invention in detail. However, the present invention is not limited to these.

reference example 1

[0110] (Reference Example 1) Measurement of Sugar Concentration

[0111] The concentrations of glucose and xylose contained in the sugar solution were quantified by comparison with standard products under the HPLC conditions shown below.

[0112] Column: Luna NH 2 (manufactured by Phenomenex)

[0113] Mobile phase: Milli-Q:acetonitrile=25:75 (flow rate 0.6mL / min)

[0114] Reaction solution: no

[0115] Detection method: RI (differential refractive index)

[0116] Temperature: 30°C.

reference example 2

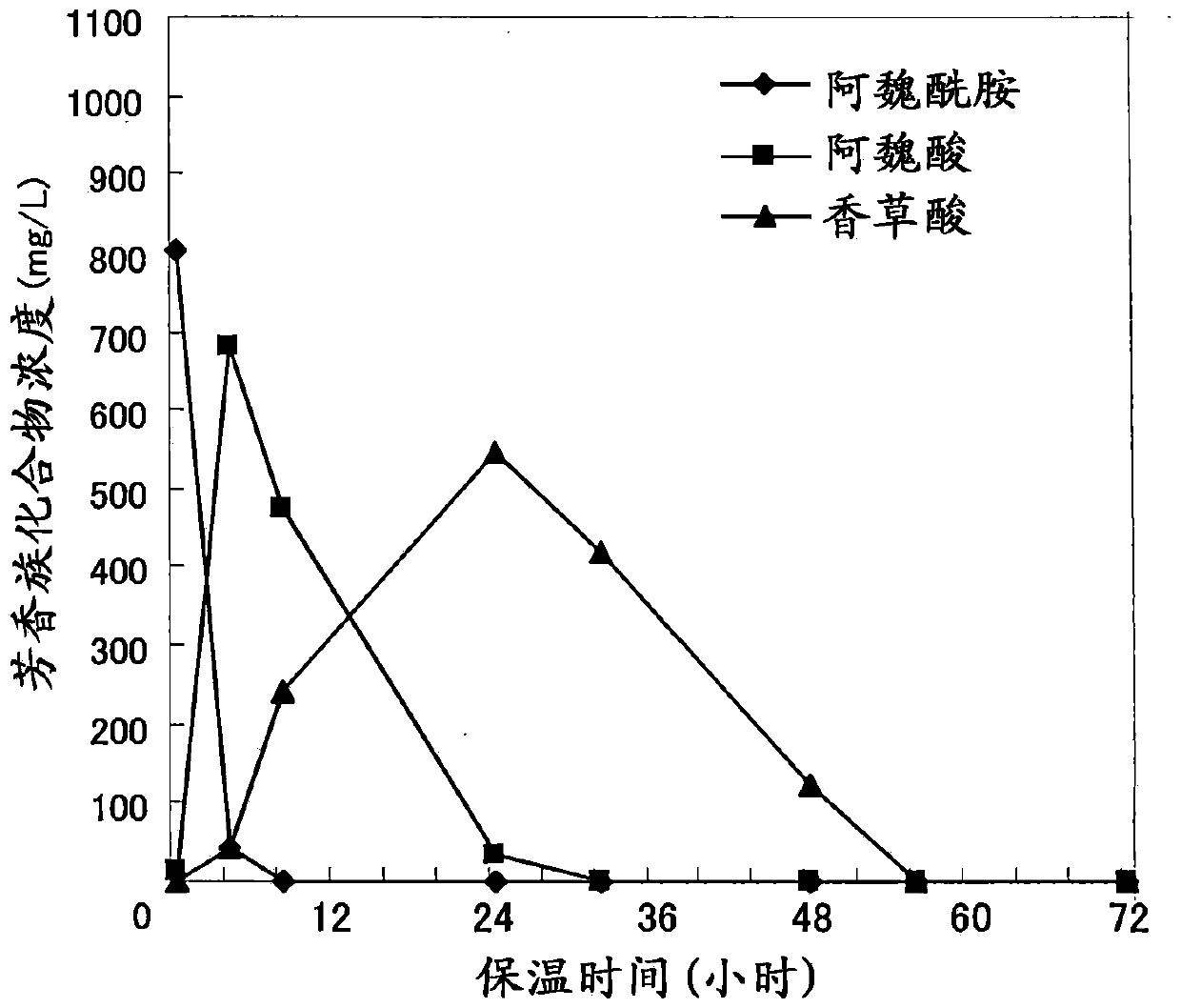

[0117] (Reference Example 2) Analysis of Fermentation Inhibiting Substances

[0118] Aromatic compounds and furan compounds contained in the hydrolyzate were quantified by comparison with standard samples under the HPLC conditions shown below. In addition, each analysis sample was centrifuged at 3500G for 10 minutes, and the supernatant was used for the analysis described below.

[0119] Column: Synergi HidroRP 4.6mm×250mm (manufactured by Phenomenex)

[0120] Mobile phase: Acetonitrile-0.1%H 3 PO 4 (flow rate 1.0mL / min)

[0121] Detection method: UV (283nm)

[0122] Temperature: 40°C.

[0123] Acetic acid and formic acid were quantified by comparison with standard products under the HPLC conditions shown below. In addition, each analysis sample was subjected to centrifugation at 3500G for 10 minutes, and the supernatant fraction was used for the analysis described below.

[0124] Column: Shim-Pack and Shim-Pack SCR101H (manufactured by Shimadzu Corporation) in series ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com