Vacuum transfer device and transfer method for realizing substrate orthogonal transfer

A handling device and vacuum technology, applied in the direction of transportation and packaging, conveyor objects, electrical components, etc., can solve the problems of poor reliability, shortened service life, high cost, etc., and achieve improved accuracy and reliability standards, improved accuracy and Reliability, interference avoidance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

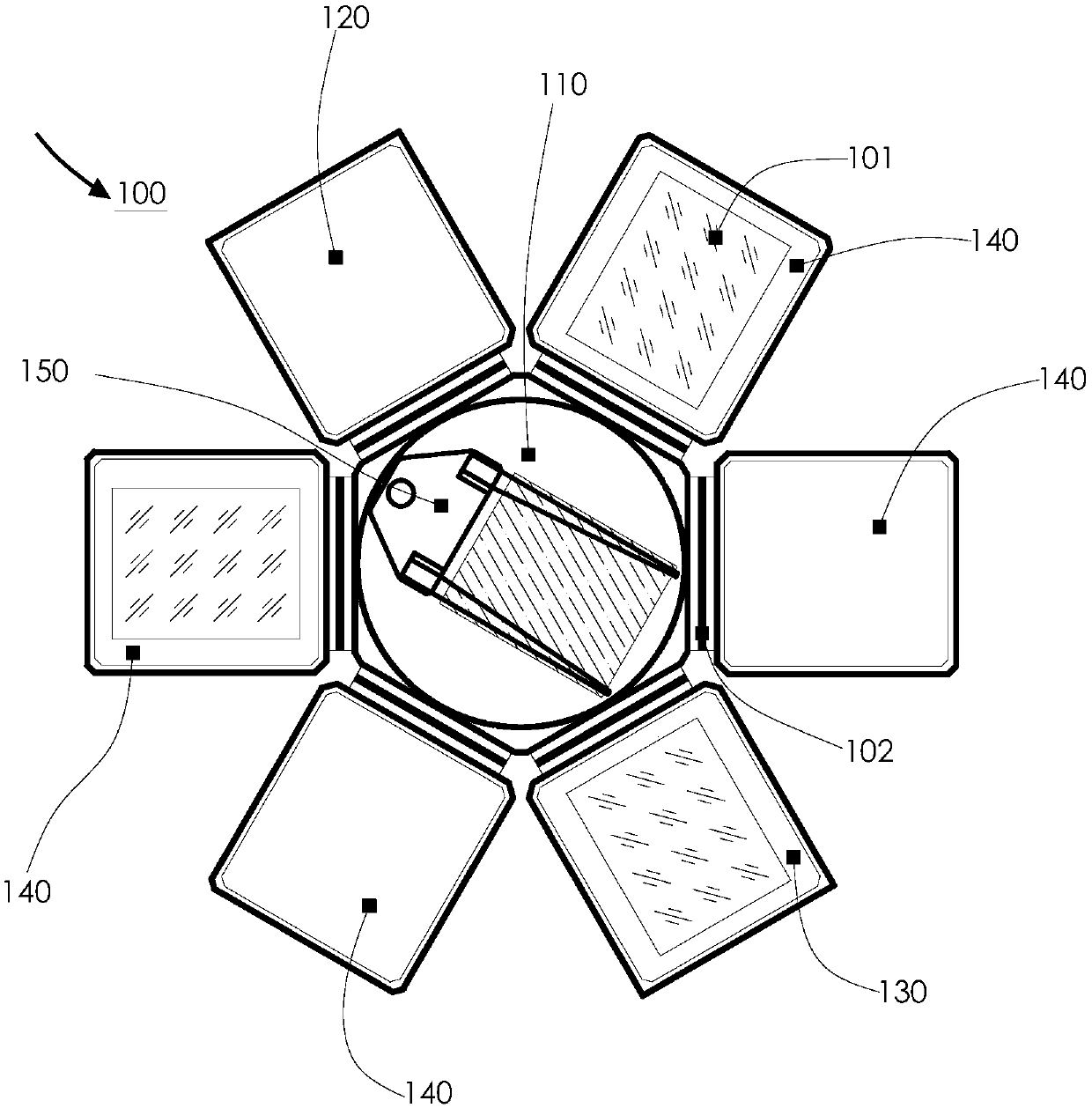

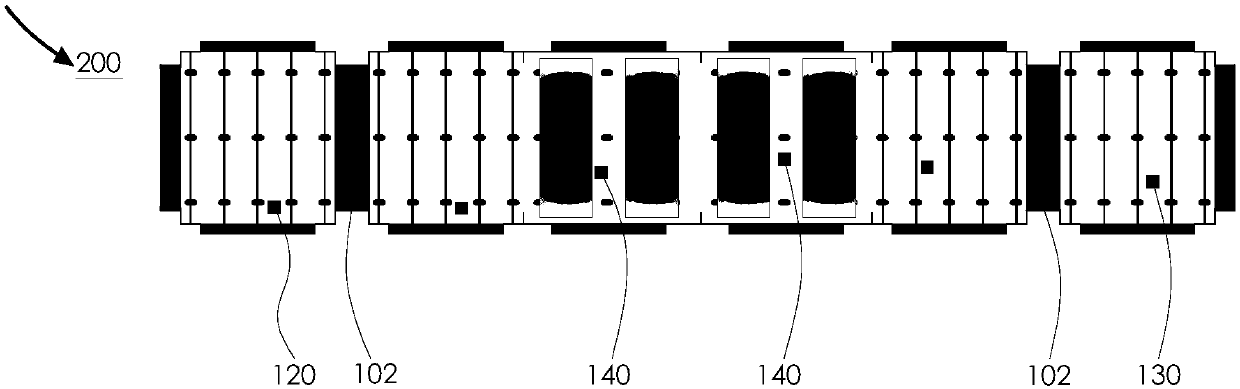

[0047] Figure 4 is a schematic plan view of the substrate processing system of the first embodiment. In this embodiment, the first direction is the "X" direction, the second direction is the "Y" direction, the "X" direction is orthogonal to the "Y" direction, and the "X" direction and the "Y" direction are both Parallel to the ground, specifically, the movement direction of the manipulator assembly carrying the substrate in the vacuum handling chamber is the "X" direction, and the movement direction of the manipulator assembly grabbing and placing the substrate from the functional chamber is the "Y" direction.

[0048] The substrate processing system 500 mainly includes: a vacuum transfer chamber 110, which is provided with a vacuum transfer device 150a capable of transferring the substrate 101 between two functional chambers, and the area of the substrate is larger than 0.5m 2 , the weight of the substrate is greater than 5Kg. The vacuum transfer device 150a can transpor...

no. 2 example

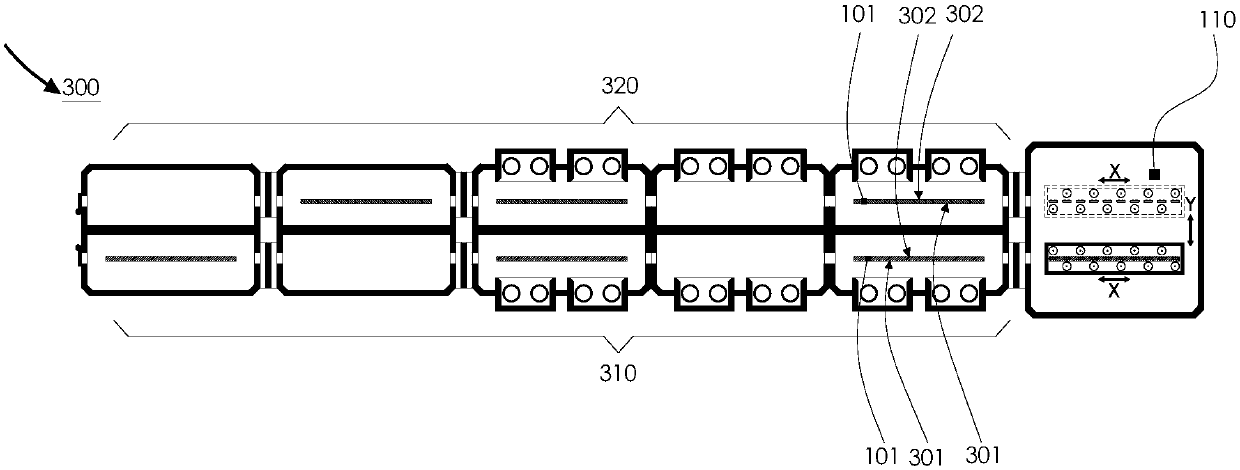

[0064] Figure 10 It is a schematic plan view of a substrate processing system 800 implementing vacuum transfer of substrates according to the second embodiment of the present invention. In this embodiment, the first direction is the "Z" direction, and the second direction is the "Y" direction," The Z" direction is orthogonal to the "Y" direction, the "Y" direction is parallel to the ground, and the "Z" direction is perpendicular to the ground. Specifically, the movement direction of the manipulator assembly carrying the substrate in the vacuum handling chamber is the "Z" direction, and the manipulator assembly The direction of motion for picking and placing substrates from the functional chamber is the "Y" direction.

[0065] The components and functions of the substrate processing system 800 in the second embodiment are basically similar to those of the substrate processing system 500 in the first embodiment. The functional chamber 140a and the second substrate processing f...

no. 3 example

[0076] combine Figure 13 , Figure 14 To further illustrate the working method of the third embodiment of the present invention, in this embodiment, the first direction is the "X" direction, and the second direction is the "Y" direction.

[0077] It has been mentioned in the previous technical problem that the ball spline transmission structure with rotating nut can be easily derived. For example, adding another set of ball splines that rotate the nut can add new ways of motion. Preamble Figure 5 and Figure 6 shows a "U"-shaped substrate processing system composed of a first substrate processing array 530a, a second substrate processing array 530b and a substrate transfer function chamber 110, if the substrate transfer in the "U"-shaped substrate processing system 500 The other side of the functional chamber 110 is also provided with a third substrate processing array 530a' and a second substrate processing array 530b', which constitutes Figure 13 A double "U" shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com