Assessment method for testing influence of electrical joint compound on reliability of electrical connection

A technology for power compound grease and power connection, which is applied in the field of testing the impact of power compound grease on the reliability of power connectors, can solve problems such as complex application environments, and achieve accurate and effective detection results.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

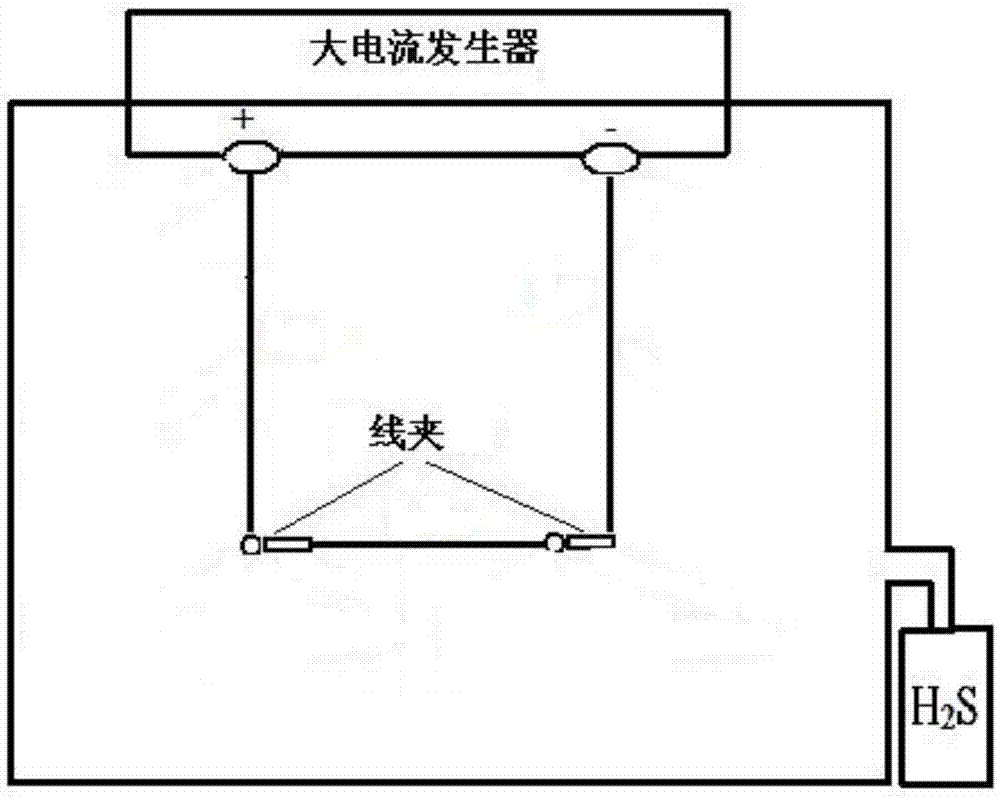

[0024] An evaluation method for testing the influence of electric compound grease on the reliability of electric connection, comprising the following steps:

[0025] Step 1: Divide the cable clips into two categories, A and B. The A category is the cable clamp not coated with compound grease on the surface, and the B category is the cable clamp coated with compound grease on the surface. Through the comparative study of the two parts of the test, the change of the temperature of the key measuring points with time and the change of the resistance of each contact surface are analyzed.

[0026] Step 2: Superpose the metal contact surfaces of the two clamps, and tighten the nuts and bolts to ensure that the bolts are tightened with the same force each time, and measure the contact resistance of the metal contact surfaces.

[0027] Use 600-grit sandpaper to polish the metal contact surface of the wire clamp before applying the electric compound grease, wipe it with clean cotton yar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com