A pressure equalization chamber, its installation method and a cross-sectional gas flow measurement device including it

An installation method and a pressure equalizing chamber technology are applied in the field of cross-sectional gas flow measurement devices, which can solve the problems of increasing airflow resistance, large cross-sectional area of pipelines, and turbulent pipeline flow fields, reducing the tendency of dust accumulation and achieving obvious energy saving advantages. , the effect of high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

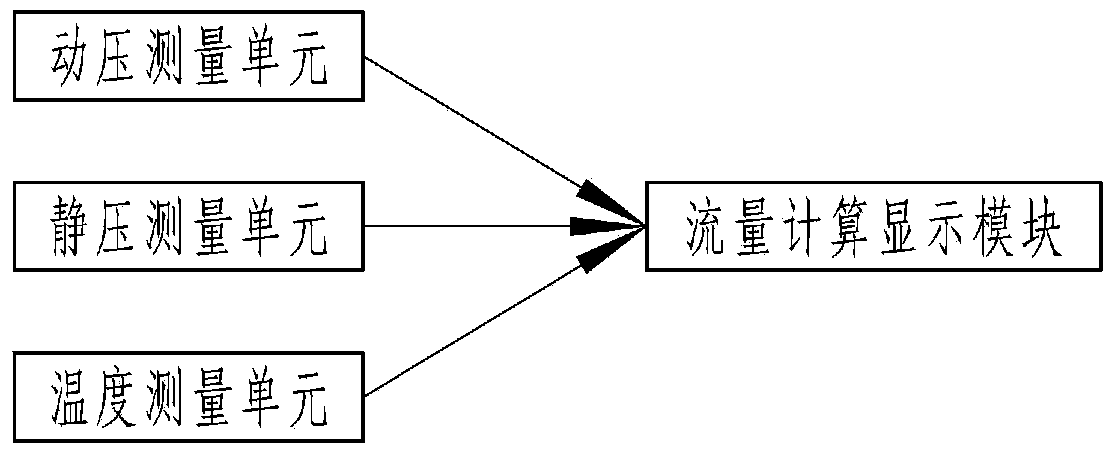

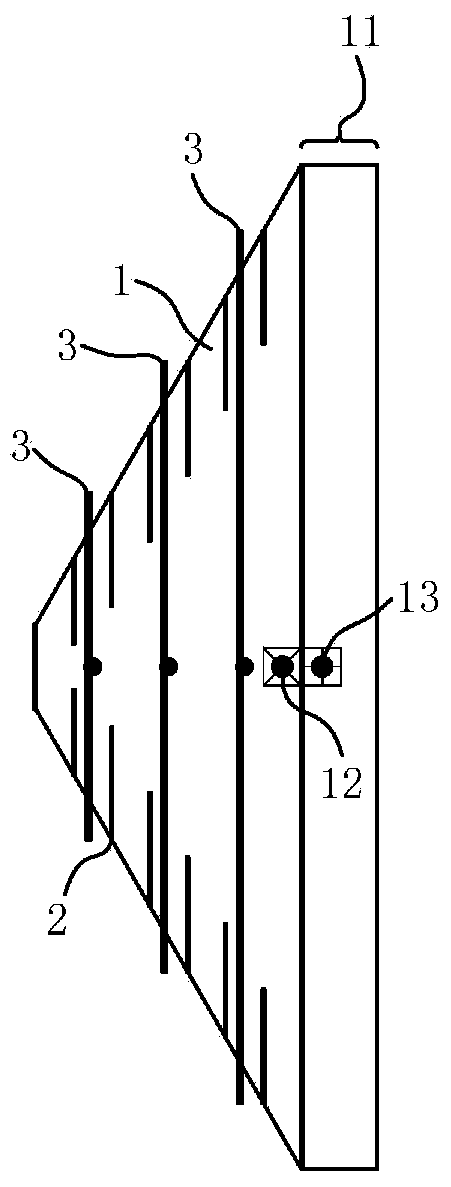

[0067] The 300MW coal-fired unit adopts a direct-blowing pulverizing system, equipped with 6 medium-speed coal mills, and the inlet of each coal mill adopts a mixed method of cold and hot primary air to adjust the temperature of the mill outlet. The above-mentioned cold primary air pipe is vertically connected to the hot primary air pipe from top to bottom, and the cross-sectional gas flow measuring device of the present invention is installed on the straight pipe section between the right-angle bend and the cold primary air control door. The complete measurement device includes dynamic pressure measurement unit, static pressure measurement unit, temperature measurement unit and flow calculation display module, such as figure 1 shown. The dynamic pressure measurement unit is composed of a pressure equalizing chamber, a full pressure taking tube, a static pressure taking tube and a differential pressure transmitter. For air flow, multiple pressure-taking ports are continuousl...

Embodiment 2

[0073] The 300MW coal-fired unit adopts a direct-blowing pulverizing system, equipped with 6 medium-speed coal mills, and the inlet of each coal mill adopts a mixed method of cold and hot primary air to adjust the temperature of the mill outlet. The above-mentioned hot primary air duct is arranged horizontally, due to the limitation of site space, the cross-sectional air volume measuring device of the present invention can only be installed downstream of the hot primary air control door, such as Figure 6 shown.

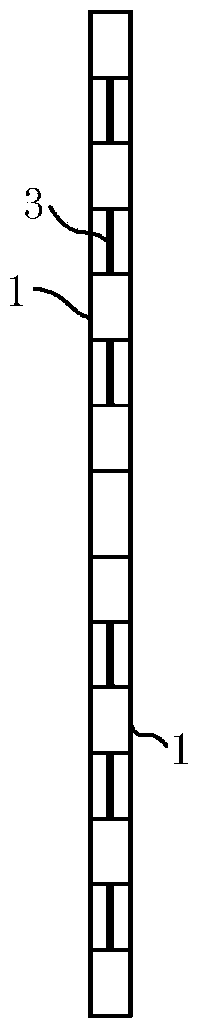

[0074] The structure of the pressure equalization chamber in this embodiment is similar to that of Embodiment 1, except for the different sizes and installation methods. The cross-section of the hot primary air duct is rectangular, with a width of 900mm and a height of 1200mm. The length of the above-mentioned pressure equalization chamber is about 1000mm, and it is vertically inserted into the hot primary air duct along the height direction. A single pressure equal...

Embodiment 3

[0078] The cross-sectional size of the hot secondary air duct of a 600MW coal-fired unit is 4500×4800mm. Due to the large cross-sectional size, short straight pipe section, low flow velocity and serious uneven distribution, conventional air volume measurement technology is difficult to meet the coordinated control requirements of the unit. Using the cross-sectional air volume measuring device of the present invention, 4×2 pressure equalization chambers are arranged in the hot secondary air duct, such as Figure 8 , 9 shown. Arranging multiple pressure equalizing chambers along the vertical insertion direction can reduce the size of a single pressure equalizing chamber, thereby reducing manufacturing costs, facilitating transportation, and facilitating on-site installation. The structure of the above-mentioned single pressure equalization chamber is similar to that of Embodiment 2, and will not be repeated here.

[0079] It needs to be added that in this embodiment, the parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com