High-pressure treatment process for Zn-Al-Cu-Mg alloy

A zn-al-cu-mg, high-pressure treatment technology, applied in the field of Zn-Al-Cu-Mg alloy high-pressure treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0008] The raw materials are made of No. 1 zinc, No. 0 aluminum, pure magnesium ingot, and Al-Cu master alloy, which are smelted in a 6kW resistance furnace. During smelting, the alloy is heated to 660~680℃, and the temperature is adjusted to 620℃ with some Zn materials.

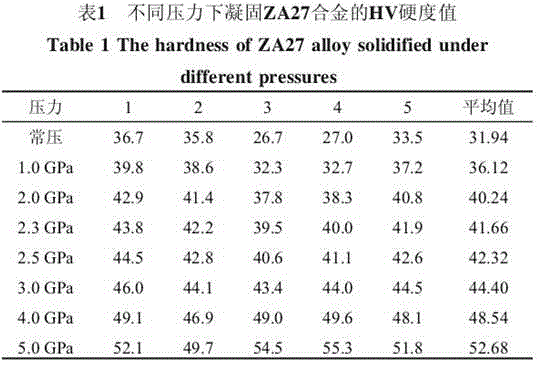

[0009] The mold is a metal mold, which is preheated to 150~200℃ before pouring. The actual composition (mass fraction) of the ZA27 alloy sample is 27.1% Al, 0.6% Cu, 0.02% Mg, and the rest is zinc. Cut the test bar into small cylindrical samples of Φ6mm×6mm. The high-pressure test was carried out on a CS-1B high-pressure six-sided top press. The sample is wrapped with BN powder, and pyrophyllite is used as a sealing and pressure-transmitting material. After raising the pressure to the specified pressure, start heating to the melting temperature of the alloy, and stop heating after maintaining the pressure for 5 minutes. After the sample is cooled to room temperature, release the pressure and take out the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com