Construction method of microbial electrochemical system for hydrogen phosphide generation reinforcement

A technology of microbial electrochemistry and construction method, applied in the field of microbial electrochemistry, to achieve the effects of convenient operation, shortened start-up time, and convenient material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

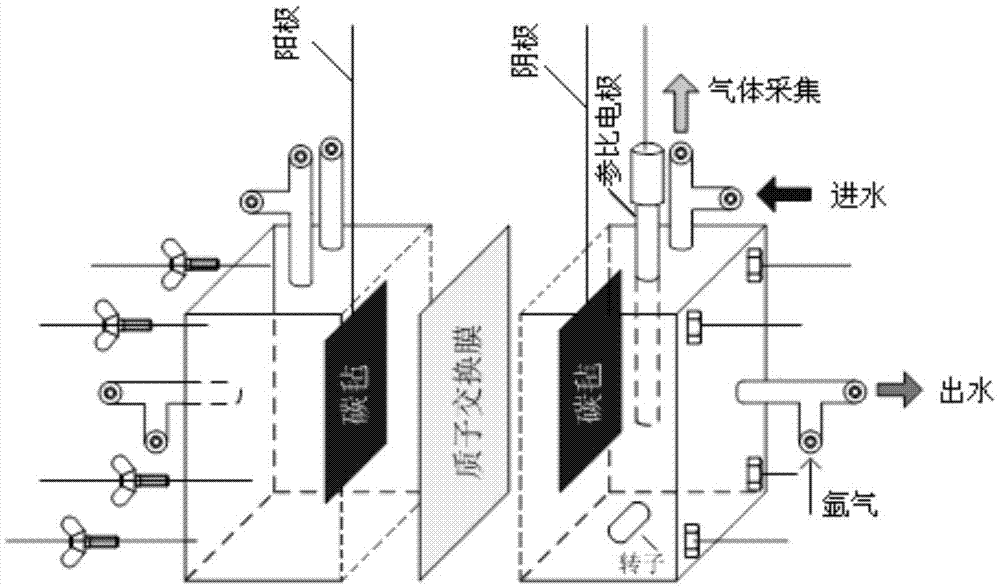

Image

Examples

Embodiment 1

[0033] (1) Enrichment culture of phosphine-producing microorganisms outside the microbial electrolytic cell: 300 g of pig manure, 300 g of anaerobic sludge and 1 L of medium were added to a 3L brown anaerobic bottle. The medium used methanol as a carbon source and COD as 800mg / L, dipotassium hydrogen phosphate as phosphorus source, TP is 50mg / L; ammonium chloride is used as nitrogen source, TN is 30mg / L. Trace element nutrient solution, the addition amount is 1ml / L. The culture medium was ventilated with argon gas for 5 minutes to remove oxygen before use, and cultured anaerobically at 35°C in an incubator, with pH 6.5 and ORP in the range of 380-400mv. Each cycle is 4 days, and the enrichment of phosphine-producing microorganisms is completed after 8 cycles to obtain a domesticated activated sludge mixture rich in phosphine-producing microorganisms.

[0034] (2) Take 10mL of the acclimated activated sludge mixture, centrifuge at 3000r / min for 10min in a centrifuge, wash with...

Embodiment 2

[0037] (1) Enrichment culture of phosphine-producing microorganisms outside the microbial electrolytic cell: 300 g of pig manure, 300 g of anaerobic sludge and 1 L of medium were added to a 3L brown anaerobic bottle. The medium used methanol as a carbon source and COD as 800mg / L, dipotassium hydrogen phosphate as phosphorus source, TP is 50mg / L; ammonium chloride is used as nitrogen source, TN is 30mg / L. Trace element nutrient solution, the addition amount is 1ml / L. The culture medium was ventilated with argon gas for 5 minutes to remove oxygen before use, and cultured anaerobically at 35°C in an incubator, with pH 6.5 and ORP in the range of 380-400mv. Each cycle is 4 days, and the enrichment of phosphine-producing microorganisms is completed after 8 cycles to obtain a domesticated activated sludge mixture rich in phosphine-producing microorganisms.

[0038] (2) Take 10mL of the acclimated activated sludge mixture, centrifuge at 3000r / min for 10min in a centrifuge, wash with...

Embodiment 3

[0041](1) Enrichment culture of phosphine-producing microorganisms outside the microbial electrolytic cell: 300 g of pig manure, 300 g of anaerobic sludge and 1 L of medium were added to a 3L brown anaerobic bottle. The medium used methanol as a carbon source and COD as 800mg / L, dipotassium hydrogen phosphate as phosphorus source, TP is 50mg / L; ammonium chloride is used as nitrogen source, TN is 30mg / L. Trace element nutrient solution, the addition amount is 1ml / L. The culture medium was ventilated with argon gas for 5 minutes to remove oxygen before use, and cultured anaerobically at 35°C in an incubator, with pH 6.5 and ORP in the range of 380-400mv. Each cycle is 4 days, and the enrichment of phosphine-producing microorganisms is completed after 8 cycles to obtain a domesticated activated sludge mixture rich in phosphine-producing microorganisms.

[0042] (2) Take 10mL of the acclimated activated sludge mixture, centrifuge at 3000r / min for 10min in a centrifuge, wash with ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com