Sio2 aerogel with thermochromic function and preparation method thereof

A thermochromic and aerogel technology, applied in the field of nanoporous materials, can solve the problems of airgel intelligence, such as too many attempts, to achieve intelligent response, thermal insulation performance, adsorption, uniform color, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

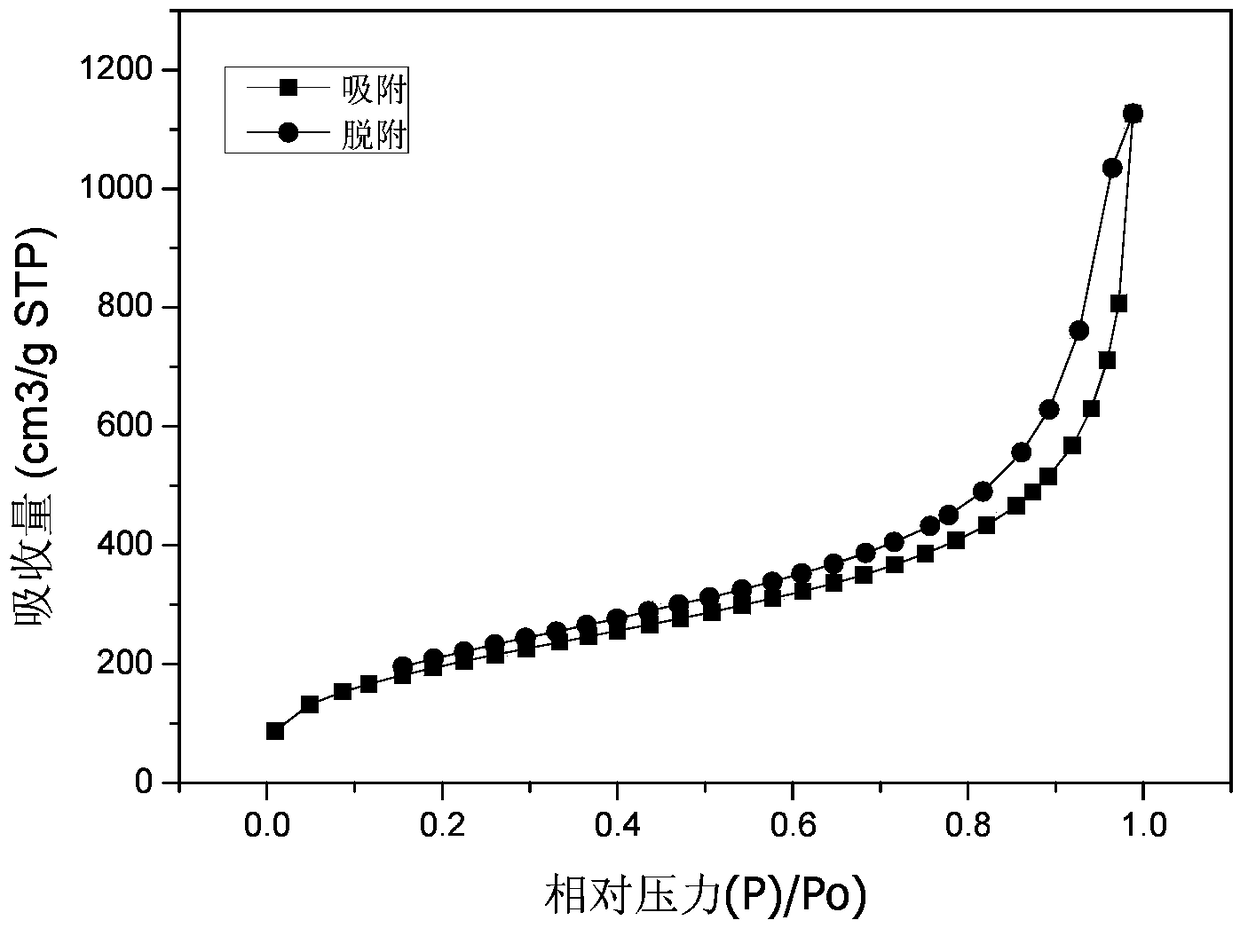

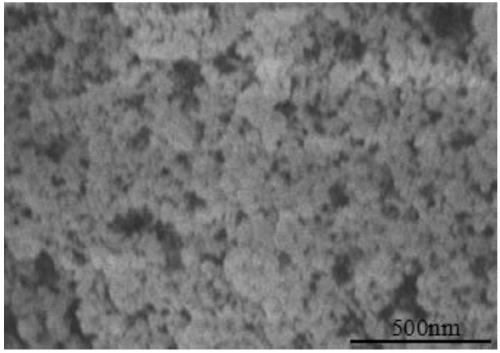

Examples

preparation example Construction

[0036] One aspect of the present invention provides a SiO with thermochromic function 2 The preparation method of airgel, it comprises the steps:

[0037] (1) Partially hydrolyze orthosilicate to form polysiloxane (also known as CS silicone oil);

[0038] (2) The polysiloxane is uniformly mixed with the color-changing microcapsule alcohol solution, alcohol, and basic catalyst to form the color-changing microcapsule / SiO 2 Complex alcohol gel (also known as temperature-changing powder / SiO 2 complex alcohol gel);

[0039] (3) the temperature variable powder / SiO 2 The complex alcohol gel is left to age for several days, and then replaced by solvent to obtain an alcohol gel with a stronger network structure;

[0040] (4) The alcohol gel is supercritically dried to obtain SiO with thermochromic function 2 airgel. In a preferred embodiment, step (1) includes: mixing a silicon source, such as an orthosilicate, with a hydrolysis catalyst and alcohol, stirring evenly, and refluxing ...

Embodiment 1

[0061] (1) Preparation of CS silicone oil: 1 mole of tetraethyl orthosilicate, 1.3 mole of dilute solution (10 -4 mol / l), ethanol (180ml), and refluxed for 10 hours for later use.

[0062] (2) Red color-changing microcapsules / SiO 2 Composite gel preparation: Take 2 parts of CS silicone oil, 3 parts of ethanol and 0.001mg / ml color-changing microcapsules in a stirring tank, drop 1-2ul concentrated ammonia water under stirring conditions, stir at 300rpm, stir for 10min and then let stand to form a compound alcohol gel.

[0063] (3) Gel aging and solvent replacement: the obtained complex alcohol gel was aged at room temperature for 3 days, and at the same time, the ethanol solvent was changed every 12 hours to make the solvent replacement sufficient, and a silica alcohol gel with complete solvent replacement was obtained.

[0064] (4) Supercritical drying: Put the obtained silica alcohol gel completely replaced by solvent in a carbon dioxide supercritical drying kettle, set the ...

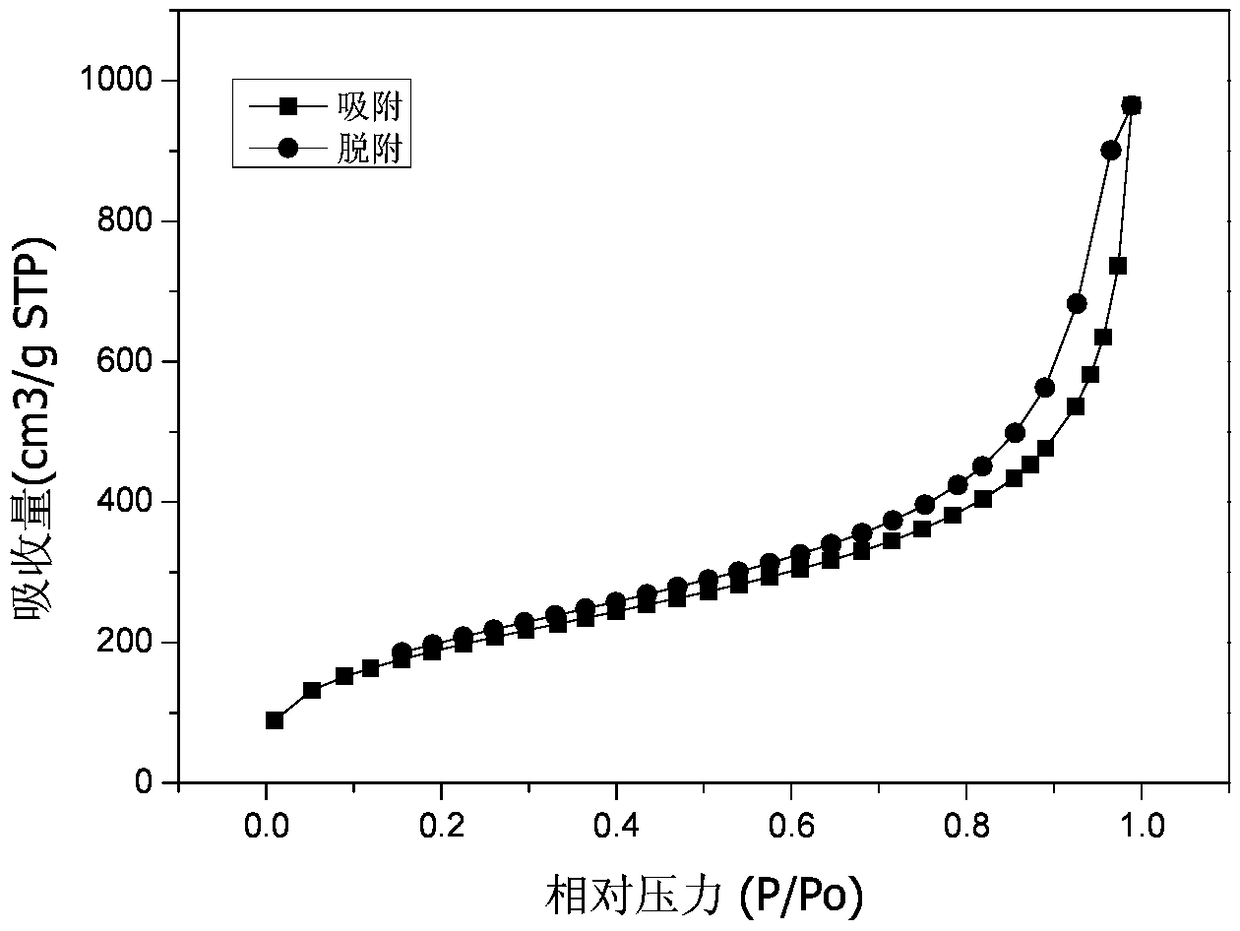

Embodiment 2

[0066] (1) Preparation of CS silicone oil: 1 mole of methyl orthosilicate, 1.3 moles of dilute acid solution (concentration of 10 -2 mol / L), ethanol (100ml) mixed, refluxed for 8h and then set aside.

[0067] (2) Pink color-changing microcapsules / SiO 2 Synthesis of composite airgel: Take 2 parts of CS silicone oil, 3 parts of ethanol, and 0.12mg / ml color-changing microcapsules in a stirring tank, add 1-2ul concentrated ammonia water under stirring, the stirring speed is 800rpm, after stirring for 30min, let it stand A complex alcohol gel is formed.

[0068] (3) Gel aging and solvent replacement: Aging the obtained composite alcohol gel at room temperature for 3 days, and at the same time changing the ethanol solvent every 12 hours to fully replace the solvent, and obtain a completely solvent-substituted silica alcohol gel.

[0069] (4) Supercritical drying: Put the obtained silica alcohol gel completely replaced by solvent in a carbon dioxide supercritical drying kettle, set...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com