Mine cable insulation shielding material and preparation method thereof

A cable insulation and shielding material technology, applied in the direction of organic insulators, plastic/resin/wax insulators, etc., can solve the problems of poor heat aging, can not be less than 33wt%, high cost, etc., achieve excellent electrical conductivity and processing performance, The effect of solving insufficient adhesion and improving heat resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

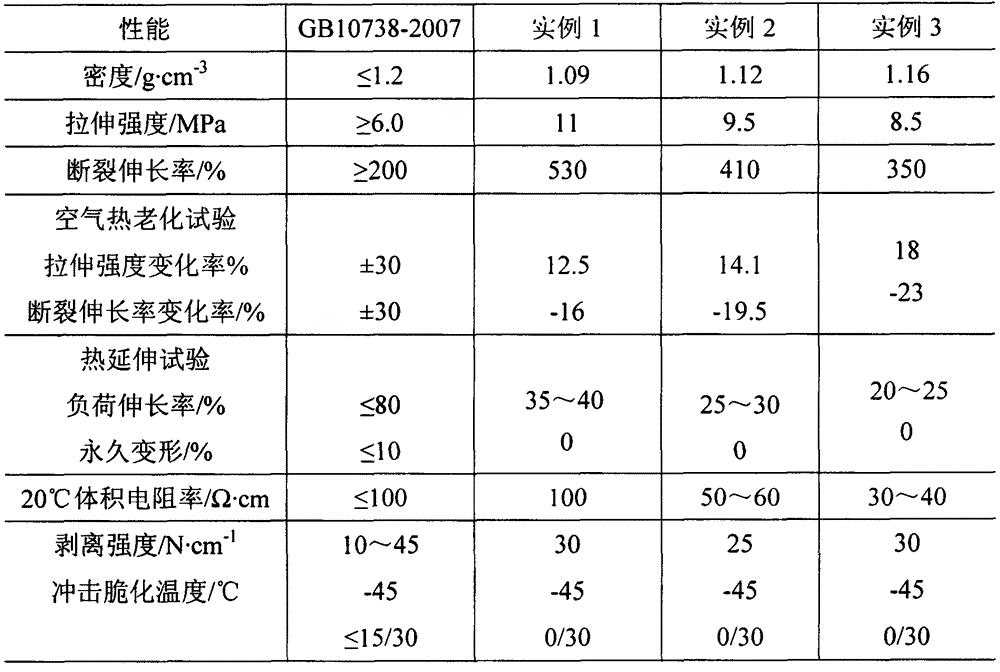

Examples

Embodiment 1

[0019] Embodiment 1: a kind of insulating shielding material that can be used for rubber insulated mine cables, by weight, its components are as follows: ethylene-vinyl acetate copolymer (EVA) 100 parts, conductive carbon black 60 parts, exchange 2.5 parts of linking agent, 3 parts of co-crosslinking agent, 8 parts of lubricant, 15 parts of softener, 1 part of antioxidant, 1.5 parts of anti-aging agent.

[0020] First, mix the conductive carbon black, lubricant, softener, antioxidant and anti-aging agent evenly for use, then adjust the roll distance of the open mill, and roll the ethylene-vinyl acetate copolymer on the open mill for 1~ After 2 minutes, add the mixed conductive carbon black, lubricant, softener, antioxidant, etc., knead for 10 minutes, and finally add the crosslinking agent and auxiliary crosslinking agent and knead for 2 to 3 minutes, thin pass 5 times, Film out.

Embodiment 2

[0021] Embodiment two: a kind of insulation shielding material that can be used for rubber insulated mine cable, by weight, its component is as follows: ethylene-vinyl acetate copolymer (EVA) 100 parts, conductive carbon black 80 parts, exchange 2.5 parts of linking agent, 3 parts of co-crosslinking agent, 8 parts of lubricant, 20 parts of softener, 1 part of antioxidant, 1.5 parts of anti-aging agent.

[0022] First, mix the conductive carbon black, lubricant, softener, antioxidant and anti-aging agent evenly for use, then adjust the roll distance of the open mill, and roll the ethylene-vinyl acetate copolymer on the open mill for 1~ After 2 minutes, add the mixed conductive carbon black, lubricant, softener, antioxidant, etc., knead for 10 minutes, and finally add the crosslinking agent and auxiliary crosslinking agent and knead for 2 to 3 minutes, thin pass 5 times, Film out.

Embodiment 3

[0023] Embodiment three: a kind of outer shielding material that can be used for rubber insulated mining cables, by weight, its composition is as follows: ethylene-vinyl acetate copolymer (EVA) 100 parts, conductive carbon black 100 parts, exchange 3 parts of linking agent, 3.5 parts of co-crosslinking agent, 8 parts of lubricant, 20 parts of softener, 1 part of antioxidant, 1.5 parts of anti-aging agent.

[0024] First, mix the conductive carbon black, lubricant, softener, antioxidant and anti-aging agent evenly for use, then adjust the roll distance of the open mill, and roll the ethylene-vinyl acetate copolymer on the open mill for 1~ After 2 minutes, add the mixed conductive carbon black, lubricant, softener, antioxidant, etc., knead for 10 minutes, and finally add the crosslinking agent and auxiliary crosslinking agent and knead for 2 to 3 minutes, thin pass 5 times, Film out.

[0025] Take a certain amount of flakes, vulcanize on a flat vulcanizer, vulcanization tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com