A refining method and device for esterification synthesis of ethyl acetate

A technology of ethyl acetate ester and refining method, which is applied in the field of pervaporation refining acetic acid and ethanol esterification method to synthesize ethyl acetate, which can solve the problems of large steam consumption, complicated operation, long process flow, etc., and achieve high safety factor , reduced operating energy consumption, simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

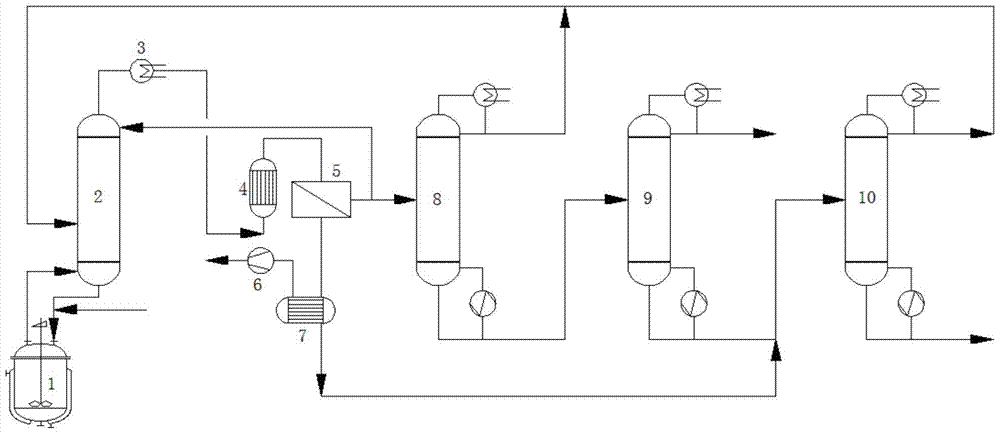

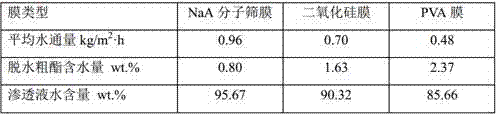

[0041] The refining method of ethyl acetate esterification synthesis, the device used is as figure 1 As shown, the operation process comprises the following steps: acetic acid, ethanol and concentrated sulfuric acid continuously enter the esterification kettle 1 to react, and the top of the esterification kettle 1 is also provided with an esterification tower 2, and the top of the esterification tower 2 obtains ethyl acetate, water, Crude ester composed of ethanol; after being condensed by the tower top condenser 3, all of it is extracted and sent to the evaporator 4, and the flow rate of the evaporator is controlled to 1500 kg / h respectively, and the crude ester is heated to 110°C and enters the evaporator in the form of steam. It consists of 12 modules made of molecular sieve membrane, silica membrane and PVA membrane (the area of each membrane module is 20 m 2) pervaporation membrane separator 5 formed in series for dehydration and separation. The pressure on the feed li...

Embodiment 2

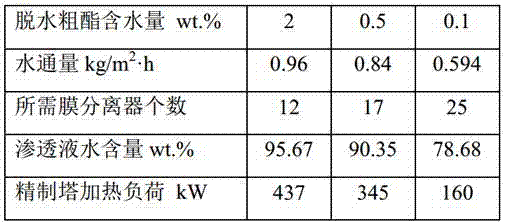

[0047] The refining method of ethyl acetate esterification synthesis, the device used is as figure 1 As shown, the operation process comprises the following steps: acetic acid, ethanol and concentrated sulfuric acid continuously enter the esterification kettle 1 to react, and the top of the esterification kettle 1 is also provided with an esterification tower 2, and the top of the esterification tower 2 obtains ethyl acetate, water, Crude esters composed of ethanol; after being condensed by the top condenser 3, all of them are extracted and sent to the evaporator 4, and the flow rate of the evaporator is controlled at 2500 kg / h. The crude esters are heated to 110°C and enter the 12 molecular sieve membrane modules (the area of each membrane module is 20 m 2 ) pervaporation membrane separator 5 formed in series for dehydration and separation. The pressure on the feed liquid side is 0.2 MPa (gauge pressure), and the pressure on the permeate side is controlled at 1500 Pa. The...

Embodiment 3

[0053] The refining method of ethyl acetate esterification synthesis, the device used is as figure 1 As shown, the operation process comprises the following steps: acetic acid, ethanol and concentrated sulfuric acid continuously enter the esterification kettle 1 to react, and the top of the esterification kettle 1 is also provided with an esterification tower 2, and the top of the esterification tower 2 obtains ethyl acetate, water, Crude ester composed of ethanol; after being condensed by the top condenser 3, all of it is extracted and sent to the evaporator 4, and the flow rate of the evaporator is respectively controlled to 3000 kg / h, and the crude ester is heated to 110°C and enters the evaporator in the form of steam. It consists of several molecular sieve membrane modules (the area of each membrane module is 20 m 2 ) pervaporation membrane separator 5 formed in series for dehydration and separation. The feed liquid side pressure is 0.2 MPa (gauge pressure), and the pe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com