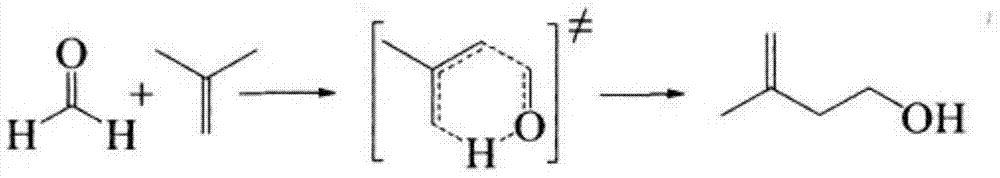

Method for synthesizing 3-methyl-3-butene-1-ol

A technology of butene and methyl, applied in the field of synthesizing 3-methyl-3-butene-1-ol, can solve the problems of low production efficiency, batch reaction mixing, high operating intensity and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

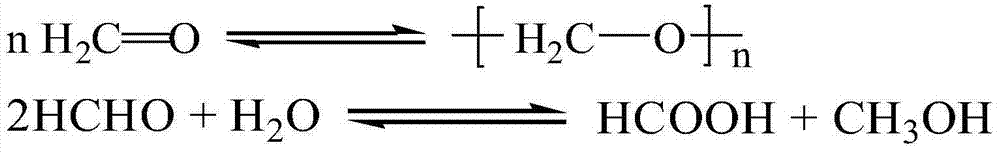

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] see figure 1 , the formaldehyde solution with methanol as the solvent (hereinafter referred to as formaldehyde methanol solution) is pressurized to 18MPa by the formaldehyde methanol solution feed pump 1, and then heated to 160°C by the formaldehyde methanol solution preheater 2, after reaching a near critical state Continuously enter the tubular reactor 5 from the top of the tubular reactor 5 with a mixing zone in the form of spray; at the same time, another raw material isobutene is pressurized to 18MPa through the isobutylene feed pump 3, and then passed through the isobutylene preheater 4 Heating to 280°C, after reaching the supercritical state, it continuously enters the tubular reactor 5 from the top side of the tubular reactor 5, and the raw material formaldehyde-methanol solution and the raw material isobutylene that reach the tubular reactor 5 through the above-mentioned process The reaction takes place in the tubular reactor 5 (reaction temperature is 280° C.,...

Embodiment 2

[0027] see figure 1 The raw material formaldehyde-methanol solution (formaldehyde solution with methanol as solvent) is pressurized to 15MPa by the formaldehyde-methanol solution feed pump 1, and then heated to 150°C by the formaldehyde-methanol solution preheater 2. Continuously enter the tubular reactor 5 from the top of the tubular reactor 5 with a mixing zone; at the same time, another raw material isobutene is pressurized to 15 MPa by the isobutene feed pump 3, and then heated to 220 by the isobutene preheater 4 °C, after reaching the supercritical state, it enters the tubular reactor 5 continuously from the top side of the tubular reactor 5, and the raw material formaldehyde methanol solution and the raw material isobutylene that reach the tubular reactor 5 through the above process are in the tubular reactor. Reaction takes place in reactor 5 (reaction temperature is 220° C., reaction pressure is 15 MPa) to obtain 3-methyl-3-buten-1-ol product. The 3-methyl-3-buten-1-o...

Embodiment 3

[0030] see figure 1 , the raw material formaldehyde methanol solution (formaldehyde solution with methanol as solvent) is pressurized to 20MPa by the formaldehyde methanol solution feed pump 1, and then heated to 200°C by the formaldehyde methanol solution preheater 2. After reaching a near critical state, it is sprayed Continuously enter the tubular reactor 5 from the top of the tubular reactor 5 with a mixing zone; at the same time, another raw material isobutene is pressurized to 22 MPa by the isobutylene feed pump 3, and then heated to 300 MPa by the isobutylene preheater 4 °C, after reaching the supercritical state, it enters the tubular reactor 5 continuously from the top side of the tubular reactor 5, and the raw material formaldehyde methanol solution and the raw material isobutylene that reach the tubular reactor 5 through the above process are in the tubular reactor. Reaction takes place in reactor 5 (reaction temperature is 300° C., reaction pressure is 22 MPa) to o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com