A method for determining the amount of pulsed laser etching of materials based on chemical reactions

A chemical reaction and pulsed laser technology, applied in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problem that the interaction cannot be considered from the perspective of phase change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

[0022] A method for determining the amount of pulsed laser etching of a material based on a chemical reaction, comprising the following steps:

[0023] 1) Determining the chemical reaction rate k: the selected material is silicon nitride, its decomposition temperature at normal pressure is 1900°C, thermal decomposition and thermal oxidation will occur at high temperature, and the chemical reaction rate at its thermal decomposition temperature is 9.5×10 4 mole m -3 ·s -1 , the chemical reaction equation of silicon nitride at high temperature has

[0024] Si 3 N 4 (s)=3Si(l)+2N 2 (g) (4-1)

[0025]

[0026]

[0027]

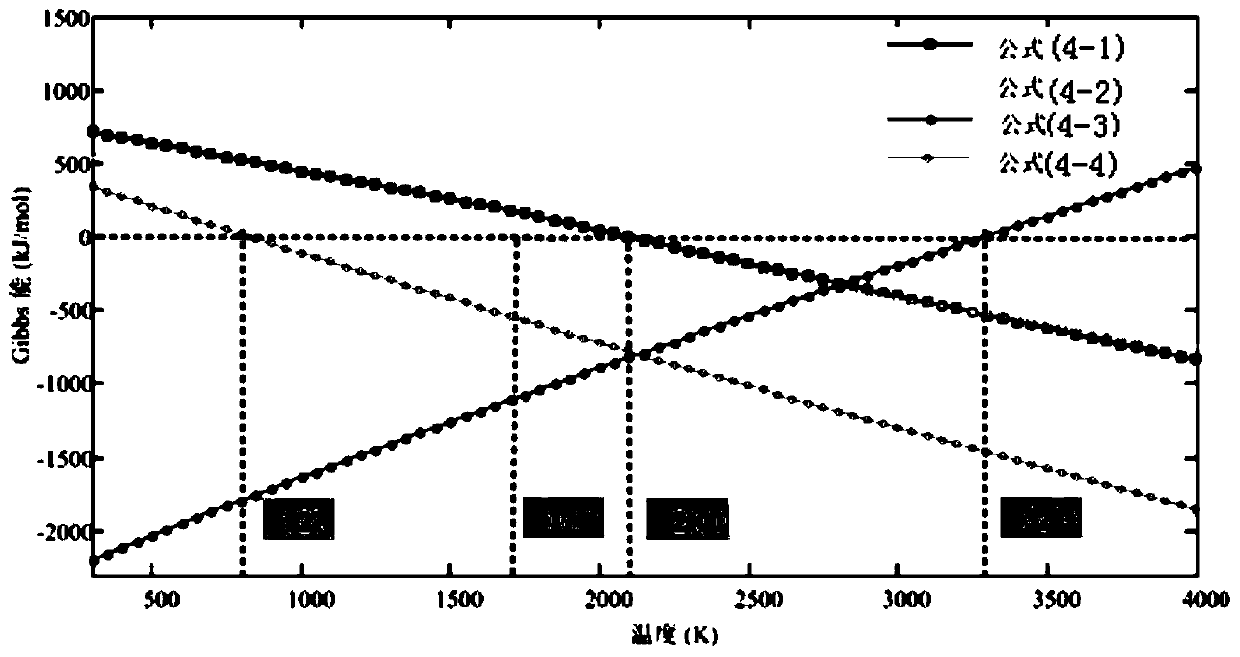

[0028] By calculating the Gibbs energy of reactants and their products, the Gibbs free energy of different chemical reactions is finally obtained, such as figure 1 shown;

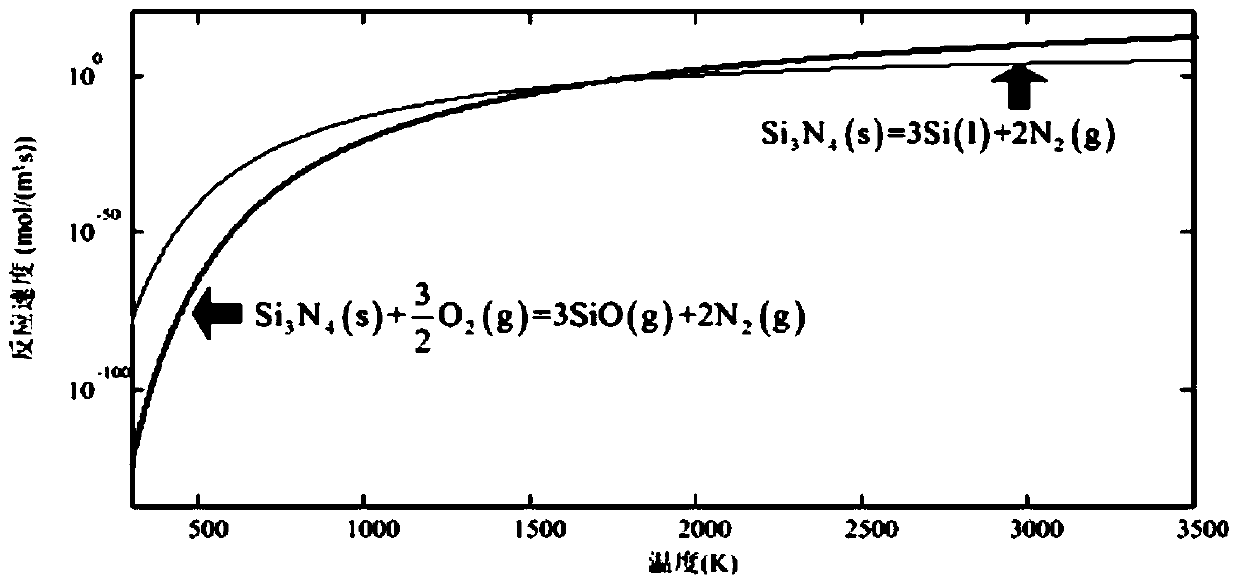

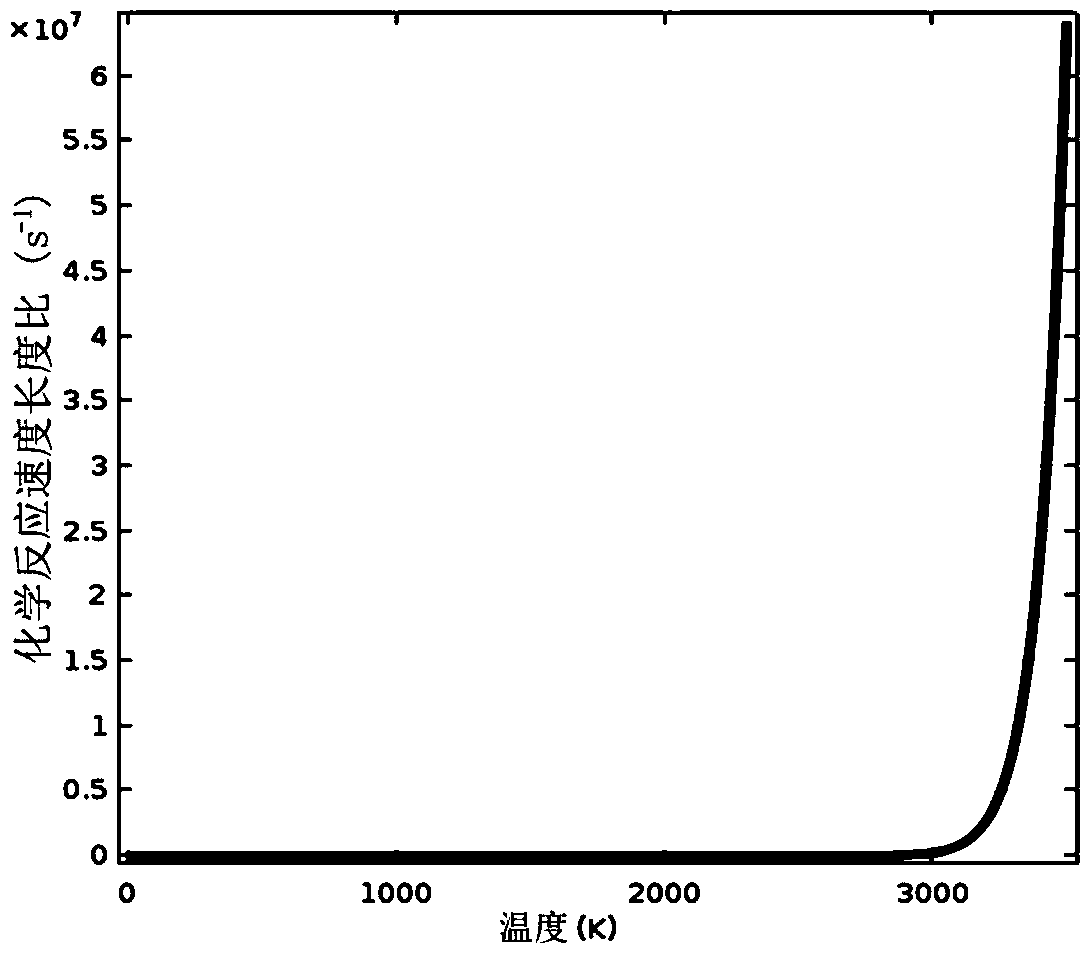

[0029] Considering that the product of re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com