A cooling device capable of forming high-density oblique jet flow

A cooling device and jet flow technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve the problems of device deformation, poor heat resistance, accelerated deterioration, etc., to prolong the life of seals, ensure flow uniformity, The effect of large cooling capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

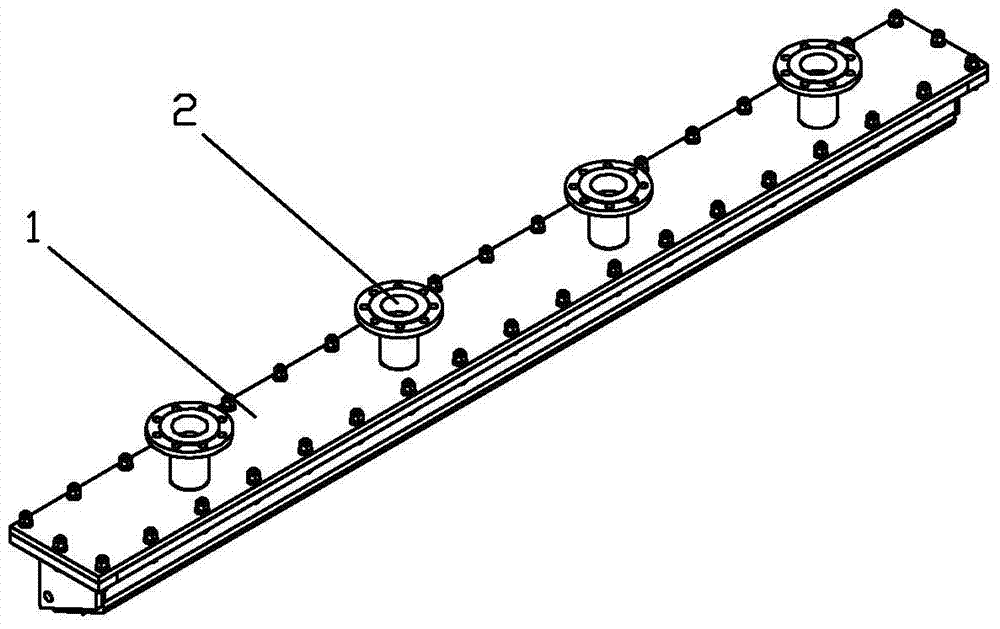

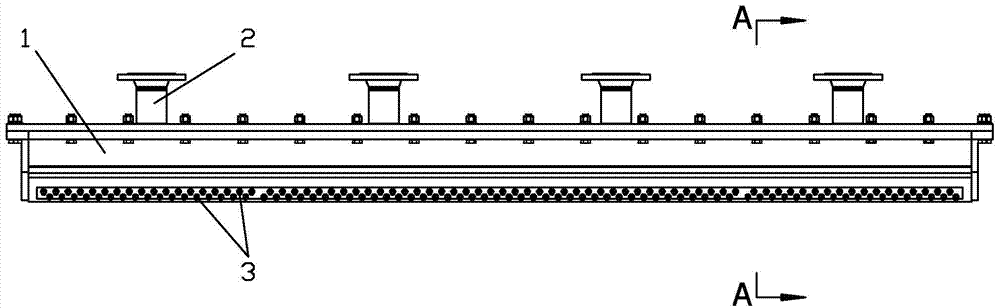

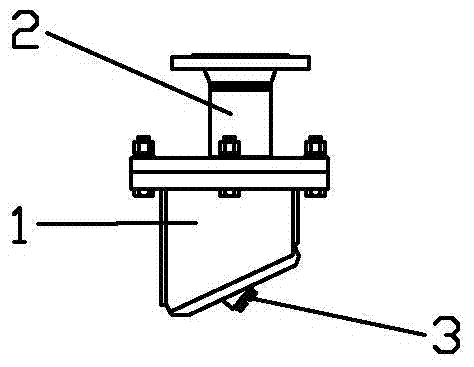

[0031] see Figure 1 to Figure 7 , a kind of cooling device that can form high-density oblique jet flow of the present invention, it comprises, body 1, is the rectangular box body structure, comprises the box body 11 of upper and lower end opening and upper cover plate 12, lower bottom plate 13; Box body The end face of the lower opening of 11 is an inclined plane; the upper cover plate 12 is provided with some through holes 121 along the length direction, and the lower base plate 13 is provided with some installation through holes 131 along the length direction; Several vertical pipes 22 arranged along the length direction of the straight pipe 21 and connecting flanges 23 at the ends of the vertical pipe 22; the two ends of the straight pipe 21 are closed, and the bottom of the straight pipe 21 is provided with some water outlet holes 211 along the length direction; the straight pipe The vertical pipes 22 on 21 are respectively inserted into the through holes 121 of the upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com