Skeleton type photoelectric composite cable and manufacturing method thereof

A technology for an optoelectronic composite cable and a manufacturing method, which is applied in the manufacture of cables/conductors, power cables including optical transmission elements, power cables, etc., can solve the problems of increasing construction costs, affecting construction efficiency, inconvenient connection, etc. The effect of good performance, reduced construction cost and low manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

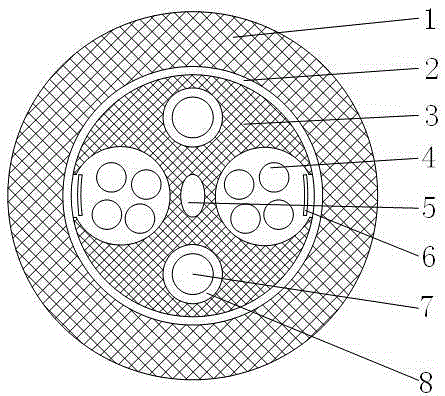

[0020] It includes an outer sheath 1, and a composite cable core is covered in the outer sheath. The cable core includes a skeleton 3, the skeleton is extruded from high-density polyethylene, and a central reinforcement 5 is arranged in the center of the skeleton. The central reinforcement mentioned above is a stranded steel wire rope; a skeleton groove with a circular radial cross-section is provided on both sides of the skeleton, the two skeleton grooves are symmetrical, and the circular skeleton groove is tangent (inscribed) to the outer periphery of the skeleton, and A skeleton slot opening is set at the tangent, and the opening width is 0.4-0.8mm larger than the outer diameter of an optical communication unit to prevent the optical communication unit in the slot from leaking out; an optical communication unit 4 is laid in the skeleton slot, and the o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| tensile load | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com