Enzyme-free glucose electrochemical sensor electrode and preparation method and application thereof

A sensing electrode and electrochemical technology, which is applied in the fields of material electrochemical variables, scientific instruments, material analysis by electromagnetic means, etc., can solve the problems of high price, cumbersome preparation process, and high sensor cost, and achieve low cost and preparation technology. Simple, highly sensitive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

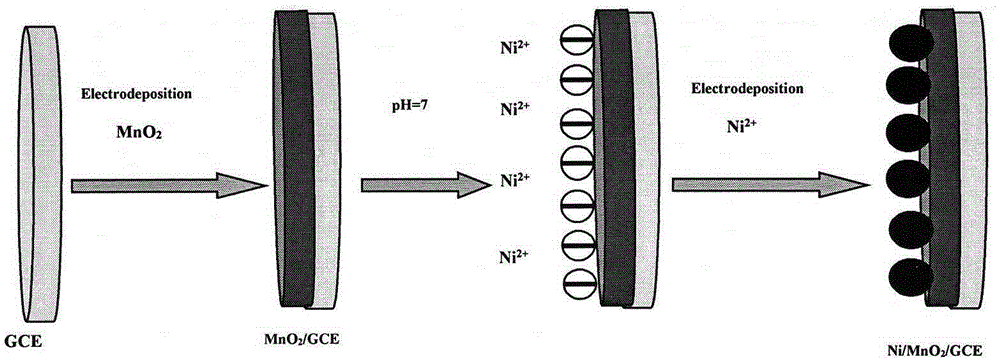

[0028] An enzyme-free glucose electrochemical sensor, the electrode used is Ni / MnO with composite structure 2 / Glassy carbon electrode, the specific preparation method of this electrode is as follows,

[0029] The glassy carbon electrode (GCE) is pretreated, and the surface of the glassy carbon electrode (GCE) is sequentially coated with γ-Al with a particle size of 1.0 μm and 0.05 μm 2 o 3 The powder was ground and polished, then ultrasonically washed with double distilled water or absolute ethanol for 10 minutes, and ventilated and dried;

[0030] Firstly, prepare the concentration of 6.0×10 -3 mol / L KMnO 4 solution and concentration of 4.0 x 10 -5 mol / L of H 2 SO 4 Solution, measure 50ml of each of the above two solutions and mix them thoroughly, then immerse the treated glassy carbon electrode at a set scanning speed of 0.002v / s, and scan 2 times in a voltage range of 0.3~-0.5V, and the obtained electrode labeled as MnO 2 / glassy carbon electrode;

[0031] Firstl...

Embodiment 2

[0034] An enzyme-free glucose electrochemical sensor, the electrode used is Ni / MnO with composite structure 2 The specific preparation method of the glassy carbon electrode is as follows,

[0035] The glassy carbon electrode (GCE) is pretreated, and the surface of the glassy carbon electrode (GCE) is sequentially coated with γ-Al with a particle size of 0.5 μm and 0.1 μm 2 o 3 The powder was ground and polished, then ultrasonically washed with twice distilled water or absolute ethanol for 20 minutes, and ventilated and dried;

[0036] Firstly, prepare the concentration of 1.0×10 -2 mol / L KMnO 4 solution and concentration of 5.0 x 10 -5 mol / L of H 2 SO 4 solution, measure 50ml with a concentration of 1.0×10 -2 mol / L KMnO 4 solution and 60ml concentration is 5.0×10 -5 mol / L of H 2 SO 4 solution, fully mix the two, and then immerse the treated glassy carbon electrode in the prepared mixed solution, set the scanning speed to 0.005v / s, and scan 2 times in the voltage ran...

Embodiment 3

[0039] In the specific measurement, the Ni / MnO prepared in Example 1 2 / Glassy carbon electrode as working electrode, saturated calomel electrode as reference electrode, platinum electrode as auxiliary electrode, connect to electrochemical workstation at the same time, and immerse the electrode in 4ml of 0.1mol / L NaOH solution, let it stand for 5min, and cycle Voltammetry scans 50-80 circles, the potential range is 0.1V-0.6V, and the scan speed is 0.1V / s to stabilize the electrodes.

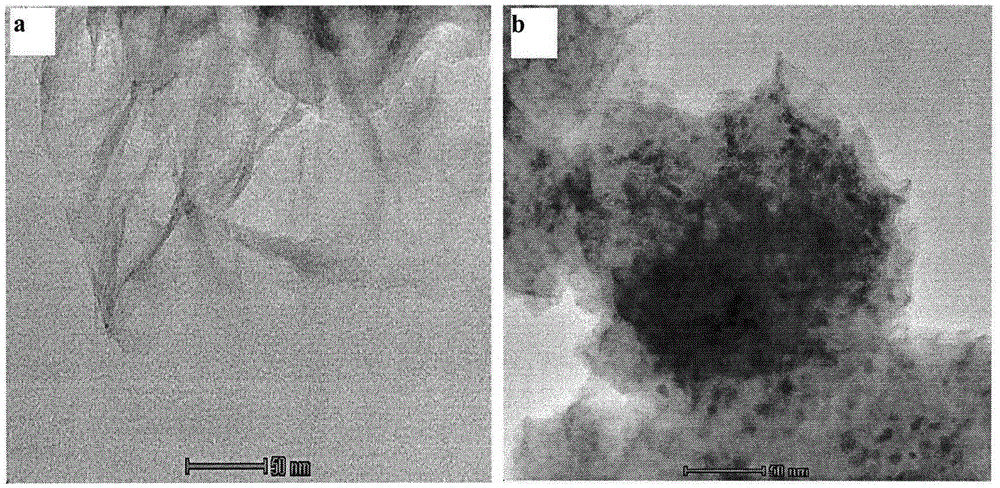

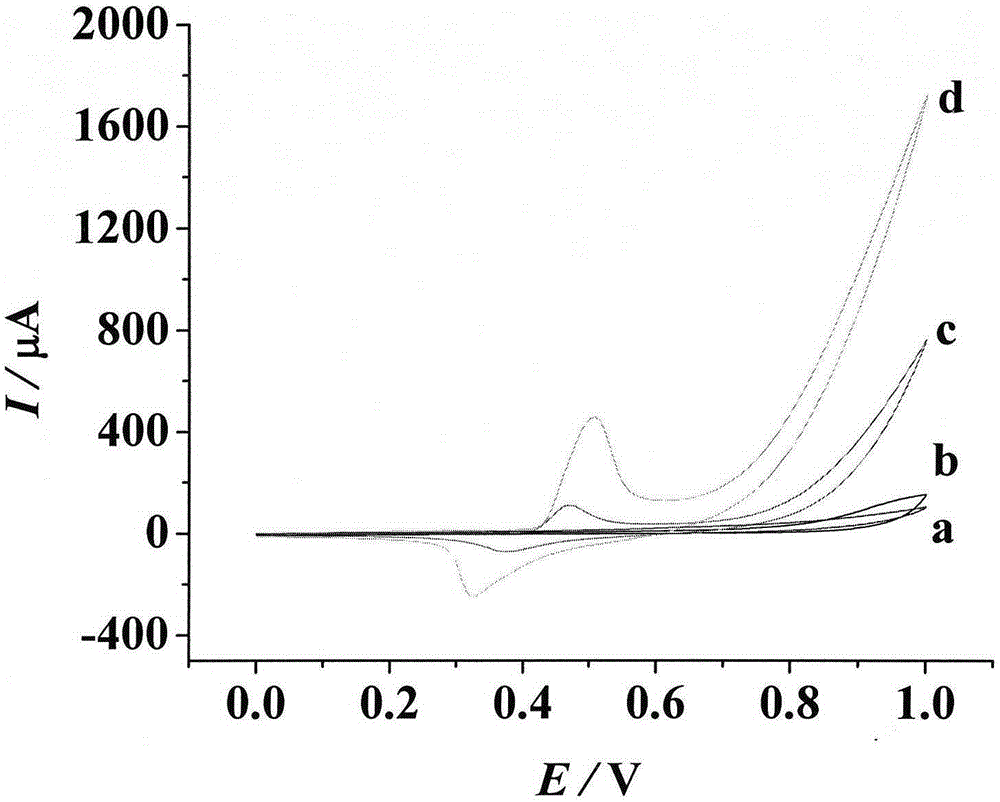

[0040] First, cyclic voltammetry scans were performed, using bare electrodes, MnO 2 Electrodes and Ni / MnO 2 electrode, the result is as figure 2 Shown, Ni / MnO 2 The catalytic response of the electrode is the most obvious.

[0041] Simultaneously use the Ni / MnO that the embodiment of the present invention 1 makes 2 / GCE electrochemical sensing electrode obtained the CV curve and i-t curve of glucose, the specific results are as follows image 3 and Figure 4 shown. In the constant potenti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com