Prestress lining structure of high-internal-pressure water conveying tunnel

A water tunnel and prestressing technology, applied in tunnel lining, shaft lining, tunnel, etc., can solve the problems of high processing and transportation costs of special-shaped steel plates, high maintenance costs, easy corrosion and rust, etc., and achieve significant social and economic benefits , Improving the service life and the effect of safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The implementation of the present invention will be described in detail below in conjunction with the accompanying drawings, but they do not constitute a limitation to the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand through the description.

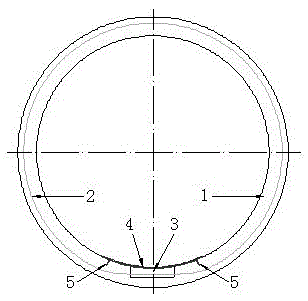

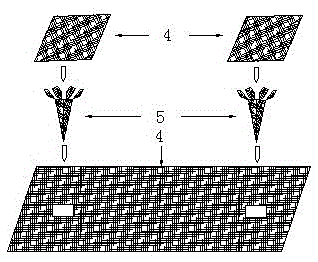

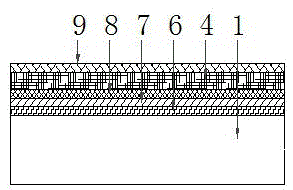

[0026] like Figure 1 ~ Figure 3 As shown, a prestressed lining structure of a high internal pressure water delivery tunnel, including reinforced concrete lining, prestressed anchor cables embedded in the lining, carbon fiber cloth pasted on the lining anchor groove and carbon fiber pins for fixing.

[0027] The two ends of the carbon fiber cloth go deep into the channels in the reinforced concrete lining through the carbon fiber pins, inject structural adhesive into the channels, and bond the carbon fiber pins and the reinforced concrete lining together through the structural adhesive.

[0028] The head of the carbon fiber pin exp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com