Ceramic piece inlaid with glass particles and manufacturing method for ceramic piece

A technology of glass particles and ceramics, applied in ceramic layered products, chemical instruments and methods, glass/slag layered products, etc., can solve the problems of high manufacturing process requirements, long production cycle, and many production processes, and achieve low cost. , The effect of saving production cost and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

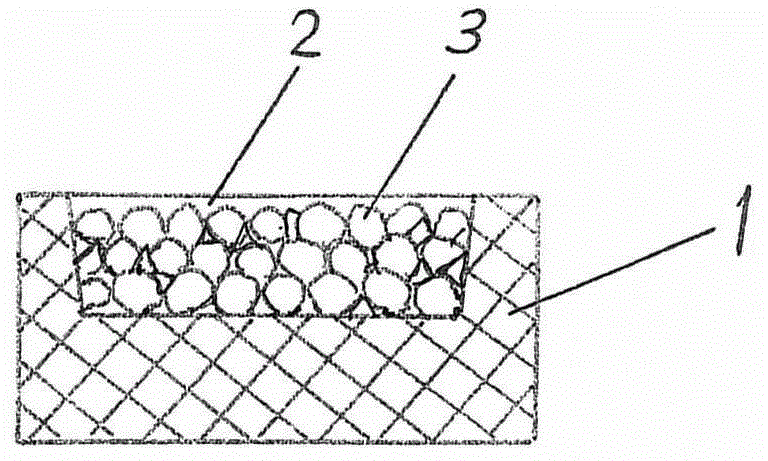

Image

Examples

Embodiment 1

[0026] (1) Use the commonly used manufacturing method of ceramic tiles to manufacture ceramic tiles with a shape conforming to the design and a concave cavity with a projected area of 30 square centimeters;

[0027] (2) Choose red broken glass particles with a mesh number of 20-200 mesh;

[0028] (3) Fill the above-mentioned glass particles into the concave cavity of the ceramic block, the height of which does not exceed the upper surface of the ceramic block, and then put the ceramic block with glass particles into the sintering furnace and heat it to 750°C. Keep warm for 20 minutes, then cool down to room temperature with the furnace and then come out of the furnace.

Embodiment 2

[0030] (1) According to the design requirements, use the commonly used manufacturing method of ceramic tiles to manufacture ceramic tiles with a shape conforming to the design and with 5 concave cavities and a projected area of 1000 square centimeters;

[0031] (2) Choose red and green broken glass particles with a mesh size of 20-100 mesh;

[0032] (3) Fill the above-mentioned glass particles into the concave cavity of the ceramic block, the height of which shall not exceed the upper surface of the ceramic block, and then put the ceramic block containing the glass particles into the heating furnace, and heat it to 850°C, Keep warm for 15 minutes, then cool down to room temperature with the furnace and then come out of the furnace.

Embodiment 3

[0034] (1) According to the design requirements, adopt the commonly used manufacturing method of ceramic tiles to manufacture ceramic tiles with a shape conforming to the design and with 10 concave cavities and a projected area of 2000 square centimeters;

[0035] (2) Choose blue and yellow mixed colors, broken glass particles with a mesh size of 20-2000 mesh;

[0036] (3) Fill the above-mentioned glass particles into the concave cavity of the ceramic block, the height of which shall not exceed the upper surface of the ceramic block, and then put the ceramic block containing the glass particles into the heating furnace, and heat it to 950°C, Keep it warm for 10 minutes, then let it cool down to room temperature with the furnace and then come out of the furnace.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Shadow area | aaaaa | aaaaa |

| Depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com