A non-bonded rib ring anchor sealing system and its installation and construction method

A construction method and non-bonding technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve the problems of limited compression of rubber pads, low reliability, oil leakage, etc. Good effect, convenient sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

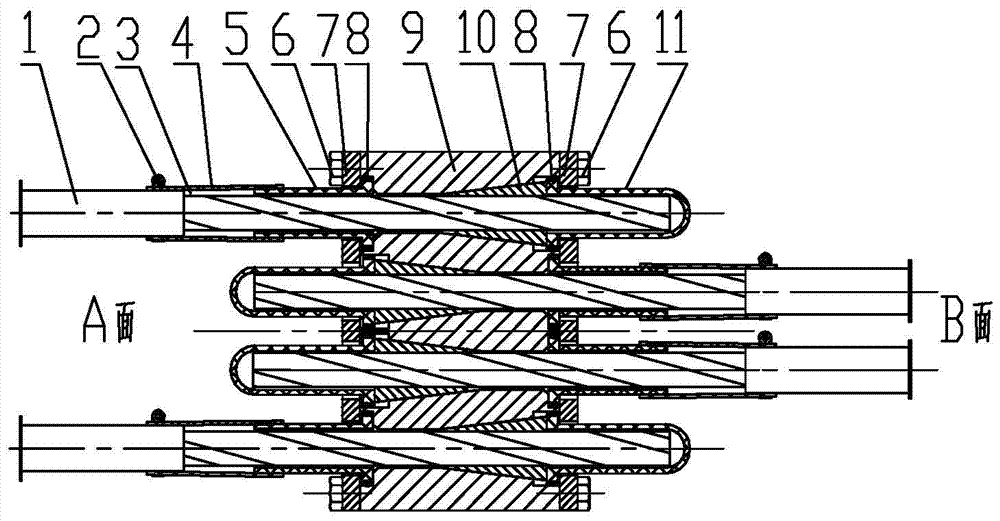

[0065] A non-bonded rib ring anchor sealing system, including an anchor plate 9 for anchoring the non-bonded rib 1, a clip 10, and the head and tail ends of the non-bonded rib 1 are respectively anchored on the A surface and the B side of the anchor plate 9 surface (see figure 1 );

[0066] The non-bonded rib ring anchor sealing system also includes a transition pipe 4, a sealing connection pipe 5, a bolt 6, a pressure plate 7, and a sealing ring 8. There are anchor plate counterbore 91 and a stepped hole at the large end of the tapered hole and the straight hole end of the anchor plate 9 respectively. 92 (see image 3 );

[0067] In the installed state, the locking ring 2, the transition pipe 4, the pressure plate 7, and the sealing connecting pipe 5 equipped with the sealing ring 8 are sequentially set on the non-adhesive rib 1, and the non-adhesive rib 1 penetrates into the corresponding hole of the anchor plate. After the tension of the clip is finished, the end surfac...

Embodiment 2

[0069] A non-adhesive tendon ring anchor sealing system, the basic structure of which is the same as that of Embodiment 1. The difference from Embodiment 1 is that the clip end does not use a sealing sleeve 11, but uses a sealing cover 12, a transition pipe 4 and a sealing connection pipe 5 Replace the sealing sleeve 11 to realize the sealing without bonding ribs at the clip end (see Figure 5 ).

Embodiment 3

[0071] A non-bonded rib ring anchor sealing system, its basic structure is the same as that of Embodiment 1 or Embodiment 2, and the difference from Embodiment 1 or Embodiment 2 is that: between the sealing sleeve 11 or the sealing connecting pipe 5 and the pressure plate 7 There is a spring washer 13, after the pressure plate 7 is fixed, the pressure plate 7 can provide the sealing force to the sealing sleeve 11 or the sealing connecting pipe 5, and tighten the clip through the sealing sleeve 11 or the sealing connecting pipe 5 (see Figure 6 , Figure 6 Shown is the sealing connection pipe 5, and the sealing sleeve 11 has a similar structure, not shown), so that its anti-loosening performance is better.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com