Brewing method for high-biostability yellow rice wine base wine

A bio-stability and rice wine technology, applied in the preparation of alcoholic beverages, etc., can solve the problems of inconvenient quality control of rice wine, low alcohol content of base wine, and occupation of labor resources, so as to improve site utilization, alcohol content, and production effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

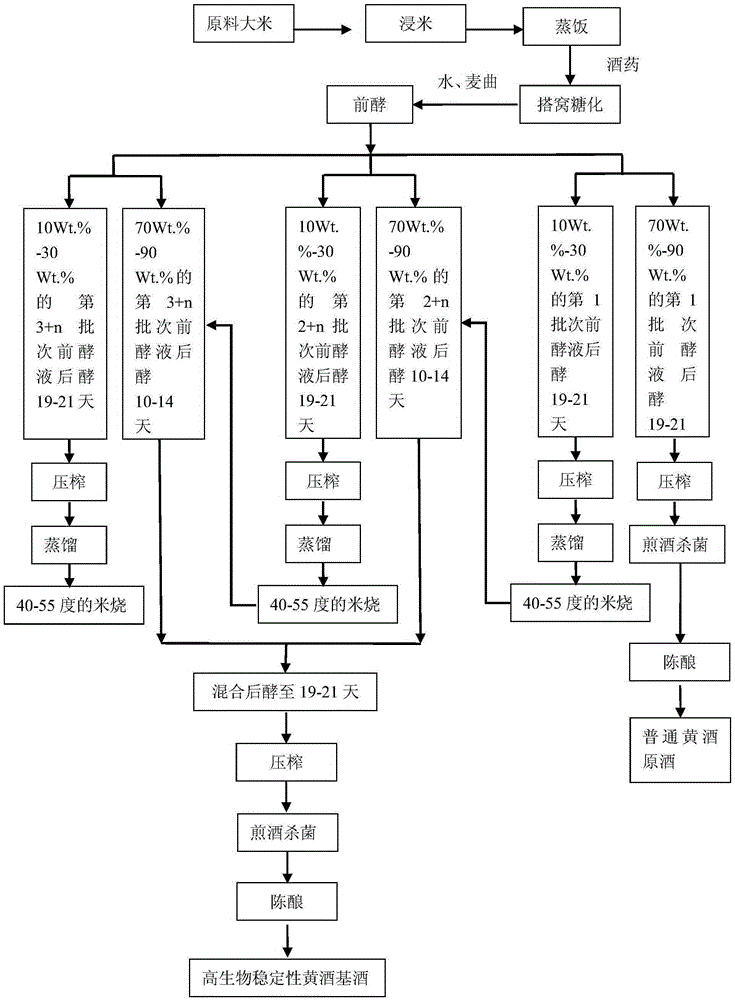

Image

Examples

Embodiment 1

[0030] 1) Take 1 ton of rice and put it into a rice soaking tank, add water to completely submerge the rice and soak for 48 hours, then wash it and put it in a rice steamer, after steaming, cool it with water to the rice temperature of 26±1°C, mix in 10 catties of wine and medicine evenly, put Put it into the stainless steel fermentation tank for pre-fermentation. Add 1 ton of water 48 hours after the start of the pre-fermentation, add 0.09±0.01 tons (8%-10%) of wheat koji and 0.5 tons of rice (after steaming) after 72 hours, and start cooking according to the product temperature after 90 hours Rake, pump into the post-fermentation tank after 120 hours, and record it as the first batch of pre-fermentation liquid.

[0031] 2) After 20 days of post-fermentation, take 10Wt.% of the first batch of pre-fermentation liquid and pump it into a plate filter press to squeeze out 0.4 tons of raw wine with an alcohol content of about 17 degrees. Atmospheric distillation is carried out to ...

Embodiment 2

[0034] 1) Take 1 ton of rice and put it into a rice soaking tank, add water to completely submerge the rice and soak for 48 hours, then wash it and put it in a rice steamer, after steaming, cool it with water to the rice temperature of 26±1°C, mix in 10 catties of wine and medicine evenly, put Put it into the stainless steel fermentation tank for pre-fermentation. Add 1 ton of water 48 hours after the start of the pre-fermentation, add 0.09±0.01 tons (8%-10%) of wheat koji and 0.5 tons of rice (after steaming) after 72 hours, and start cooking according to the product temperature after 90 hours Rake, pump into the post-fermentation tank after 120 hours, and record it as the first batch of pre-fermentation liquid.

[0035] 2) After 20 days of post-fermentation, take 20% of the first batch of pre-fermentation liquid and pump it into a plate filter press to squeeze out 0.8 tons of raw wine with an alcohol content of about 17 degrees. Atmospheric distillation is carried out to it,...

Embodiment 3

[0038] 1) Take 1 ton of rice and put it into a rice soaking tank, add water to completely submerge the rice and soak for 48 hours, then wash it and put it in a rice steamer, after steaming, cool it with water to the rice temperature of 26±1°C, mix in 10 catties of wine and medicine evenly, put Put it into the stainless steel fermentation tank for pre-fermentation. Add 1 ton of water 48 hours after the start of the pre-fermentation, add 0.09±0.01 tons (8%-10%) of wheat koji and 0.5 tons of rice (after steaming) after 72 hours, and start cooking according to the product temperature after 90 hours Rake, pump into the post-fermentation tank after 120 hours, and record it as the first batch of pre-fermentation liquid.

[0039]2) After 20 days of post-fermentation, take 30% of the first batch of pre-fermentation liquid and pump it into a plate filter press to squeeze out 1.2 tons of raw wine with an alcohol content of about 17 degrees. Atmospheric distillation is carried out to it, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com