System and method for preparing high-octane gasoline, jet fuel, and naphthenic base oil from full-hydrogen coal tar

A high-octane gasoline and naphthenic base oil technology, which is applied in chemical instruments and methods, hydrocarbon oil treatment, petroleum industry, etc., can solve problems such as inability to make full use of resources, low cetane number, and large investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

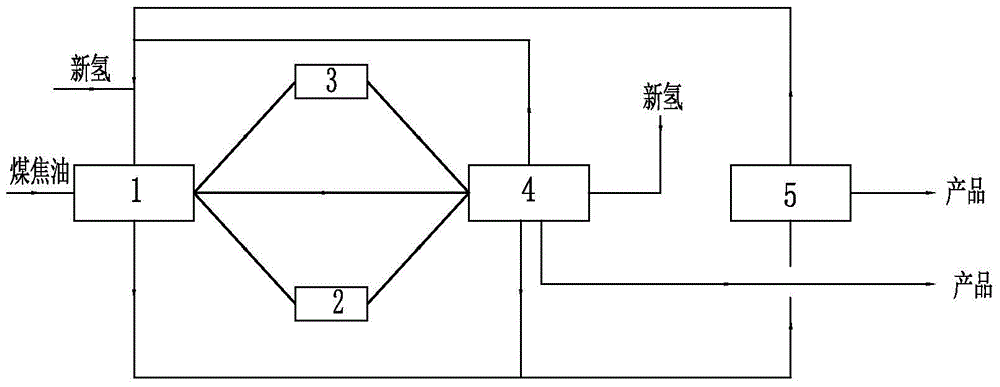

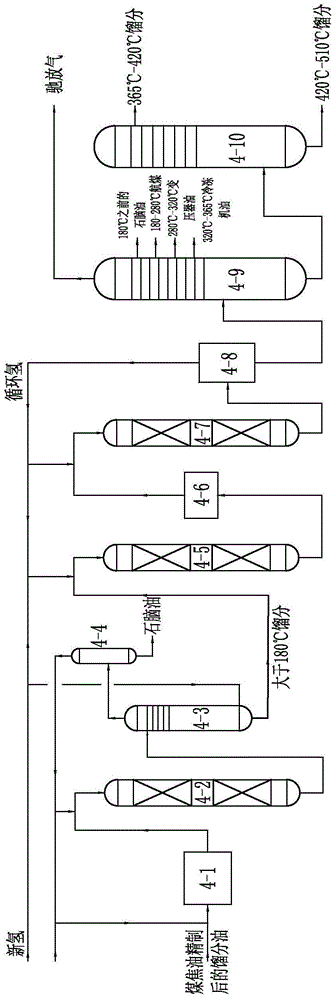

[0068] In the system of this embodiment, the output port of the coal tar refining device 1 is connected to the input port of the deep refining of distillate oil, isomerization depressurization and post-refining device 4 through the intermediate tank 3 of medium and low temperature distillate oil and the intermediate tank 2 of high temperature distillate oil respectively. Pass.

[0069] The method for preparing high-octane gasoline, jet fuel and naphthenic base oil by adopting above-mentioned system is realized by following steps:

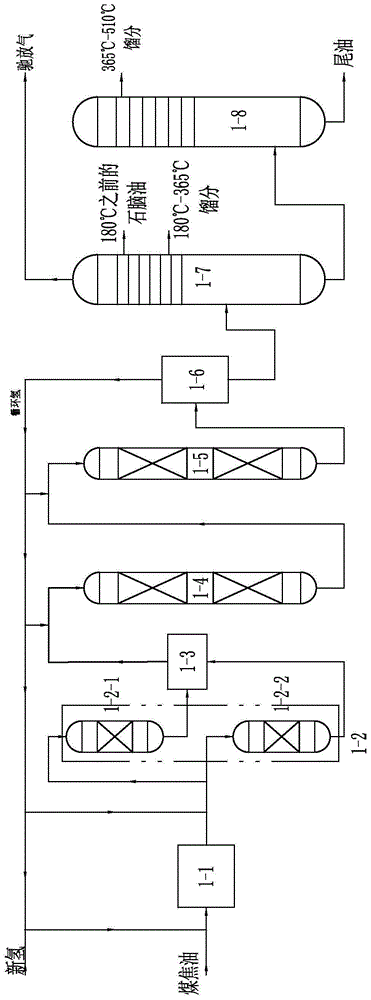

[0070] (1) Coal tar refining

[0071] After deslagging, dehydration, and desalination pretreatment, the whole distillate medium-low temperature coal tar is heated to 220°C by the tar heating furnace 1-1 after hydrogen mixing, and then enters the tar primary reactor 1-2 and the tar heat exchanger 1- 3. Tar secondary reactor 1-4, tar tertiary reactor 1-5, generated oil high pressure separator 1-6, generated oil atmospheric fractionation tower 1-7, ge...

Embodiment 2

[0098] In the system of this embodiment, the output port of the coal tar refining device 1 is connected to the input port of the deep refining of distillate oil, isomerization depressurization and post-refining device 4 through the intermediate tank 3 of medium and low temperature distillate oil and the intermediate tank 2 of high temperature distillate oil respectively. Pass.

[0099] The method steps of adopting above-mentioned system to prepare high-octane gasoline, jet fuel and naphthenic base oil are as follows:

[0100] (1) Coal tar refining

[0101] After pretreatment of deslagging, dehydration and desalination, the whole distillate medium-low temperature coal tar and the hydrogen-mixed raw material are heated to 260°C by the tar heating furnace 1-1, and then enter the tar primary reactor 1-2 and the tar heat exchanger in turn 1-3, tar secondary reactor 1-4, tar tertiary reactor 1-5, produced oil high pressure separator 1-6, produced oil atmospheric fractionation tower...

Embodiment 3

[0128] In the system of this embodiment, the output port of the coal tar refining device 1 is connected to the input port of the deep refining of distillate oil, isomerization depressurization and post-refining device 4 through the intermediate tank 3 of medium and low temperature distillate oil and the intermediate tank 2 of high temperature distillate oil respectively. Pass.

[0129] Adopt above-mentioned system to prepare high-octane gasoline, jet fuel and naphthenic base oil method steps as follows:

[0130] (1) Coal tar refining

[0131] After deslagging, dehydration, and desalination pretreatment, the whole distillate medium-low temperature coal tar is heated to 240°C by the tar heating furnace 1-1 after hydrogen mixing, and then enters the tar primary reactor 1-2 and the tar heat exchanger 1- 3. Tar secondary reactor 1-4, tar tertiary reactor 1-5, generated oil high pressure separator 1-6, generated oil atmospheric fractionation tower 1-7, generated oil vacuum fraction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com