A kind of preparation method of chlorinated rubber

A technology of chlorinated rubber and chlorination reaction, applied in the field of preparation of chlorinated rubber, can solve the problems of uneven chlorination, low degree of chlorination, poor solubility, etc., and achieve good solubility, less insoluble particles and high transparency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

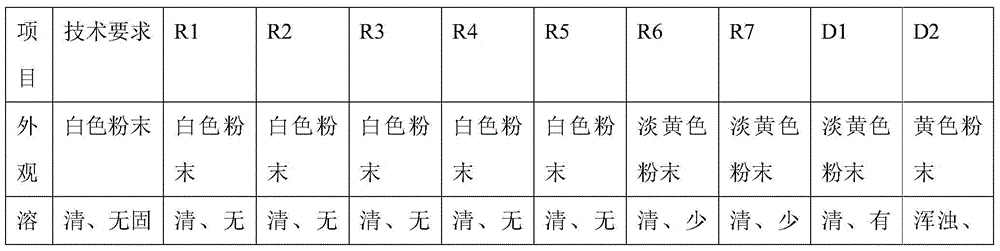

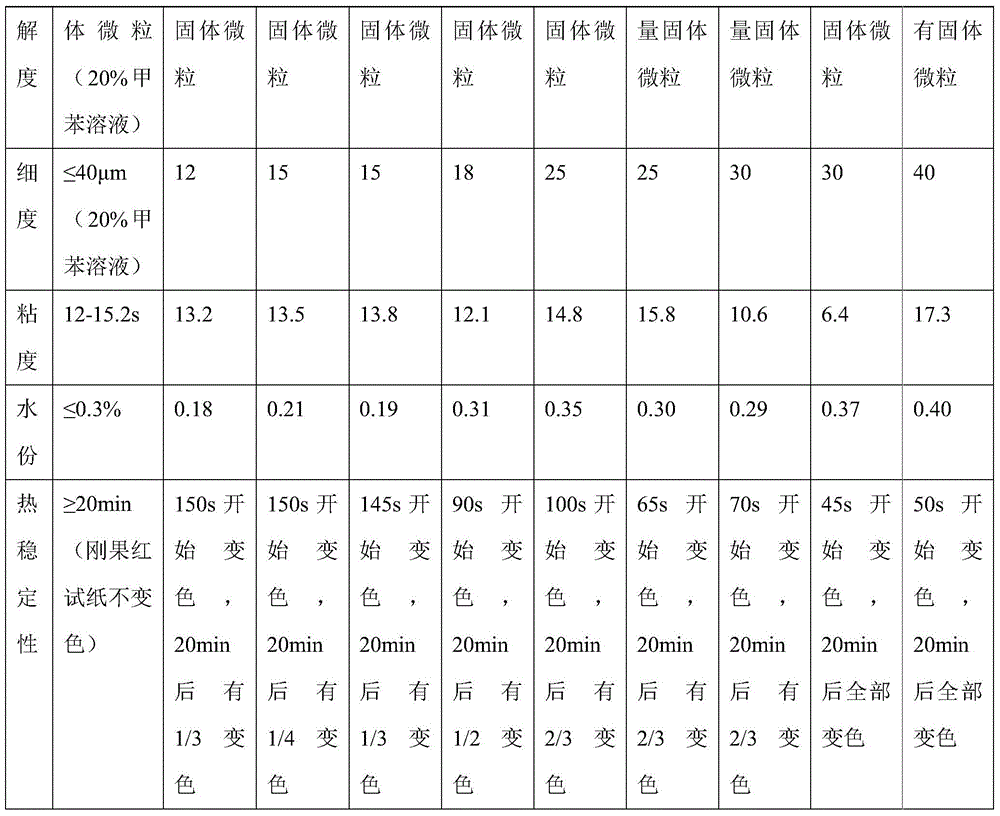

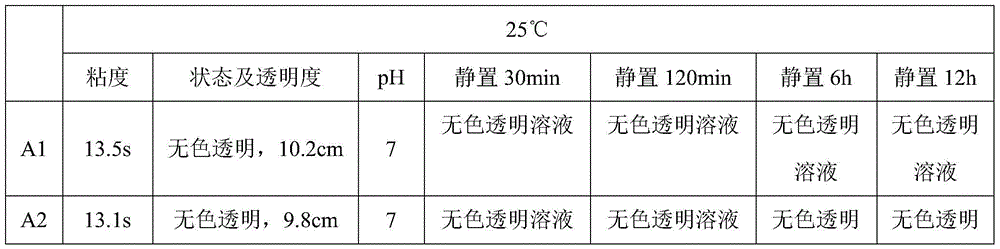

Examples

Embodiment 1

[0026] A kind of preparation method of chlorinated rubber, this preparation method comprises the following steps:

[0027] (1) Add 30Kg of natural rubber and 0.9Kg of polyethylene wax (the number average molecular weight is 3000) into the reaction kettle containing the reaction medium and auxiliary agents, stir for 20min, and compound the weight ratio of polyethylene to reaction medium and auxiliary agents 1:12:0.15, the reaction medium is 15% hydrochloric acid aqueous solution;

[0028] (2) Chlorine is added to the reactor to carry out a chlorination reaction to obtain the crude chlorinated rubber product. The conditions of the chlorination reaction include: first reacting at 93° C. for 2 hours, then cooling to 58° C. for 2.5 hours; in the chlorination reaction , the amount of chlorine gas introduced is 5 times the weight of natural rubber;

[0029] (3) The crude chlorinated rubber product obtained in step (2) is subjected to deacidification treatment, and the deacidificatio...

Embodiment 2

[0032] A kind of preparation method of chlorinated rubber, this preparation method comprises the following steps:

[0033] (1) Add 30Kg of natural rubber and 3Kg of polyethylene wax (number average molecular weight is 2500) into the reactor containing reaction medium and auxiliary agent, stir for 20min, the weight ratio of natural rubber to reaction medium and auxiliary agent is 1: 10:0.08, the reaction medium is 10% aqueous hydrochloric acid;

[0034] (2) Chlorine is added to the reactor to carry out a chlorination reaction to obtain the crude chlorinated rubber product. The conditions of the chlorination reaction include: first reacting at 95° C. for 3 hours, then cooling to 55° C. for 2 hours; in the chlorination reaction , the amount of chlorine gas introduced is 4 times of the weight of natural rubber;

[0035] (3) The crude chlorinated rubber product obtained in step (2) is subjected to deacidification treatment, and the deacidification treatment includes: transporting ...

Embodiment 3

[0038] A kind of preparation method of chlorinated rubber, this preparation method comprises the following steps:

[0039] (1) 30Kg of natural rubber and 1.5Kg of polyethylene wax (number average molecular weight is 3000) are added in the reactor that contains reaction medium and auxiliary agent, stir 20min, the weight ratio of natural rubber and reaction medium and auxiliary agent is 1 : 15: 0.02, the reaction medium is 15% aqueous hydrochloric acid;

[0040] (2) Chlorine is added to the reactor to carry out a chlorination reaction to obtain the crude chlorinated rubber product. The conditions of the chlorination reaction include: first reacting at 90° C. for 3 hours, then cooling to 60° C. for 3 hours; in the chlorination reaction , the amount of chlorine gas introduced is 6 times of the weight of natural rubber;

[0041] (3) The crude chlorinated rubber product obtained in step (2) is subjected to deacidification treatment, and the deacidification treatment includes: trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com