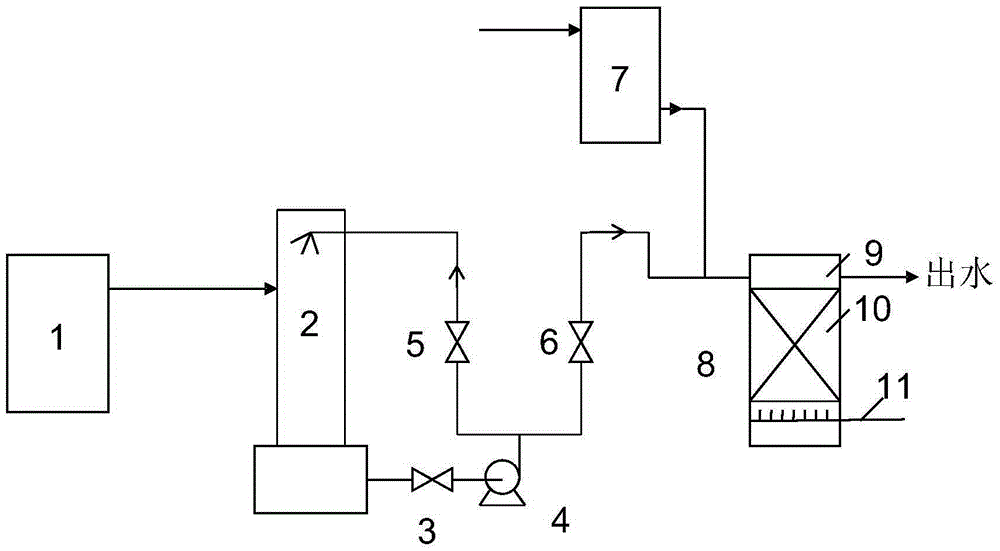

Chlorine dioxide catalytically-oxidizing apparatus used for waste water treatment

A chlorine dioxide catalytic oxidation tower and chlorine dioxide technology are applied in water/sewage treatment, flotation water/sewage treatment, special compound water treatment, etc. It can improve the contact efficiency, enhance the catalytic oxidation effect, and achieve the effect of safe operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

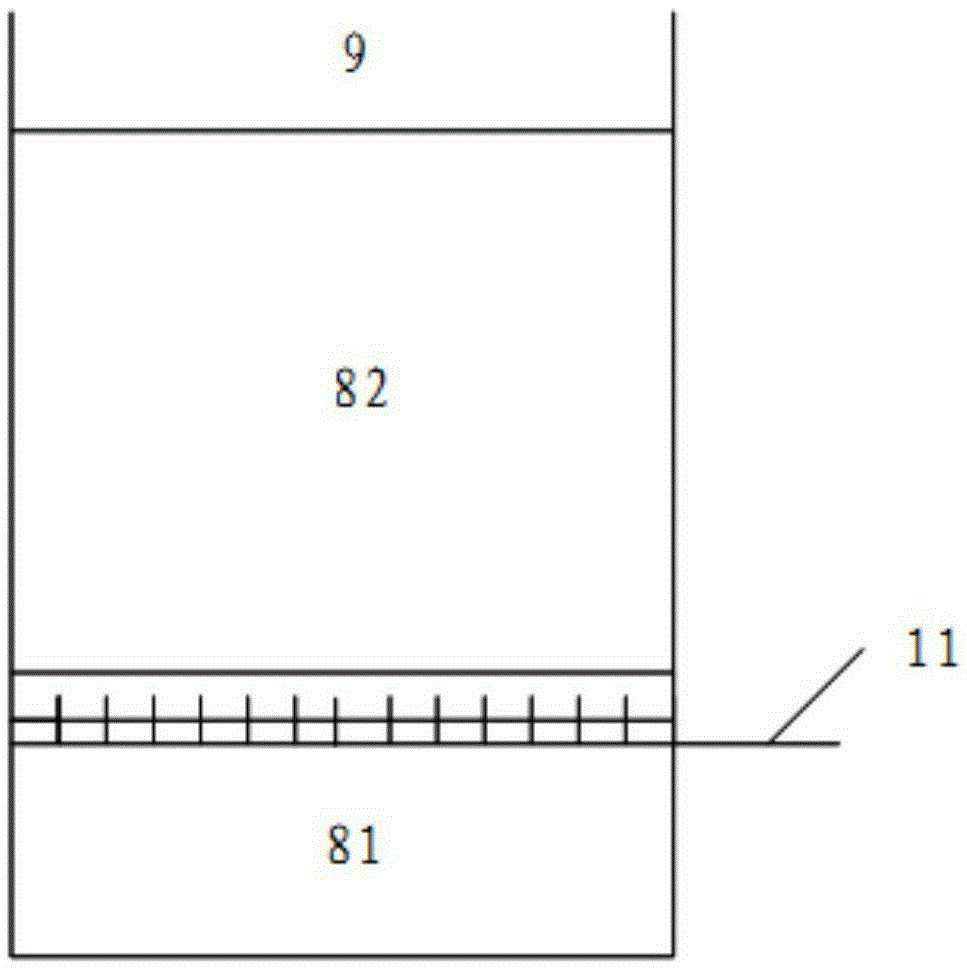

Method used

Image

Examples

Embodiment 1

[0024] The chemical oxygen demand (COD) that is used to produce purified terephthalic acid (PTA) workshop is the waste water of 4200mg / L, is processed with the chlorine dioxide catalytic oxidation device of the present invention, and use volume ratio is 0.5% dichloride in the treatment. Chlorine oxide aqueous solution (concentration is 500mg / L), in the aeration treatment, the volume ratio of air to wastewater is 105:1 to 110:1, pH=5~6, and the residence time of wastewater in the catalytic oxidation tower is kept at 60min. The COD of the final wastewater is reduced to 450mg / L, which enhances the biodegradability of the wastewater, and after aeration treatment reaches the standard, it enters the next-level biochemical treatment system.

Embodiment 2

[0026] Refinery oily wastewater, wastewater COD=5100mg / L, oily 80mg / L, through the chlorine dioxide catalytic oxidation device, is processed with the chlorine dioxide catalytic oxidation device of the present invention, and the volume ratio used in the treatment is 15% chlorine dioxide Aqueous solution (concentration is 1000mg / L), in the aeration treatment, the volume ratio of air and waste water is 105-110:1, pH=6-7, keep the residence time of waste water in the catalytic oxidation tower as 90min, the treated waste water The COD is reduced to 420mg / L, and the oil content is 10mg / L, which enhances the biodegradability of the wastewater, and after aeration treatment reaches the standard, it enters the next-level biochemical treatment system.

Embodiment 3

[0028] Acidic dark green B printing and dyeing wastewater, wastewater COD=850mg / L, is processed through the chlorine dioxide catalytic oxidation device of the present invention, and the dosing volume ratio is 0.8% chlorine dioxide aqueous solution (concentration is 800mg / L), in aeration treatment In the process, the volume ratio of air to waste water is 105-110:1, pH=5, and the residence time of waste water in the catalytic oxidation tower is kept at 45 minutes. The COD of the treated waste water is reduced to 200 mg / L, and after aeration treatment reaches the standard, it enters The next-level biochemical treatment system enhances the biodegradability of wastewater, and after aeration treatment, it enters the next-level biochemical treatment system after reaching the standard.

[0029] As can be seen from the foregoing examples, the chlorine dioxide catalytic oxidation device of the present invention can significantly reduce the COD value in the wastewater after treatment, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com