Full-automatic tensioning control system and method used for rubber belt machine

A control method and tape machine technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve problems such as slipping, belt machine overtension, and difficulty in ensuring accuracy, so as to avoid slipping, improve the degree of automation, The effect of accurate tension value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The technical solutions of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

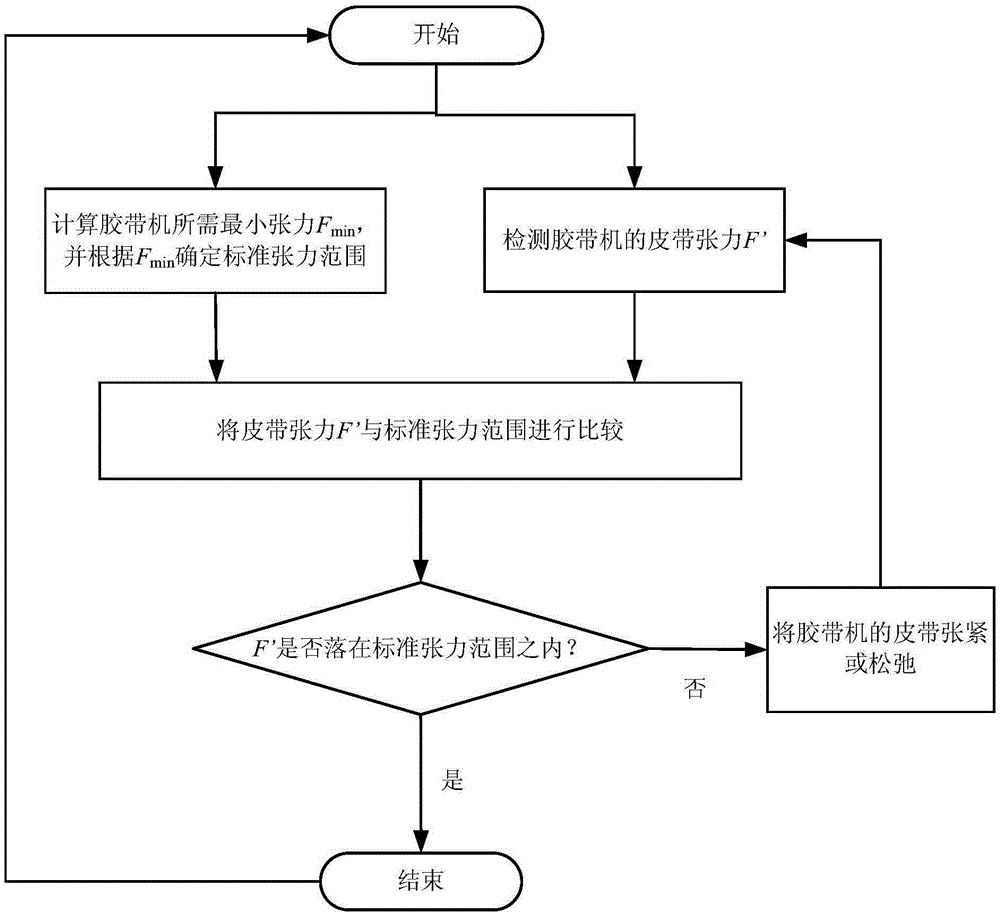

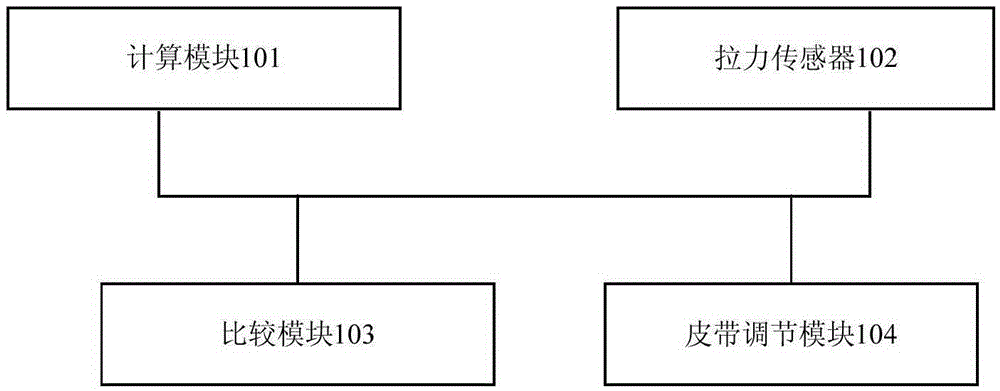

[0014] figure 1 A flow chart showing a fully automatic tension control method according to an embodiment of the present invention, figure 2 is the structural block diagram of the corresponding fully automatic tension control device, when working:

[0015] During the start-up, shutdown or operation of the tape machine, the calculation module 101 calculates the required minimum tension F of the tape machine based on the following formula min , and according to F min Determine the standard tension range;

[0016]

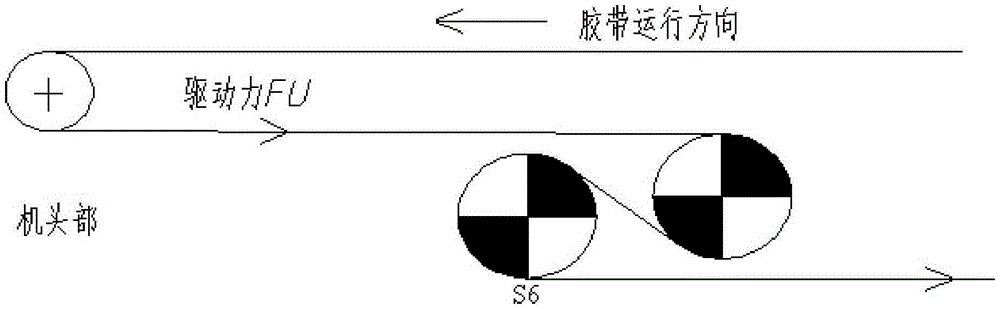

[0017] in, f U is the driving force of the main engine, M is the torque of the drive inverter, I is the reduction ratio of the reducer, R is the radius of the pulley, μ is the friction coefficient between the belt surface and the pulley, is the wrapping angle of the i-th drum;

[0018] Tension s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com