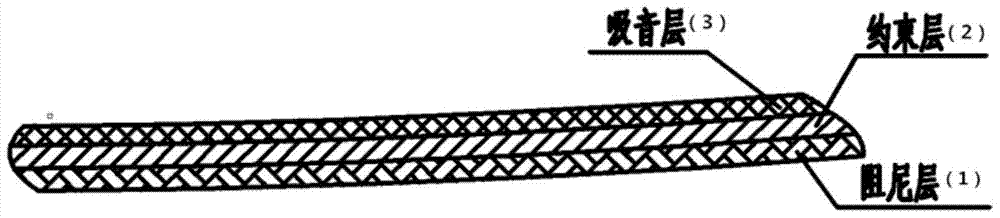

A kind of constrained damping noise reduction plate and its preparation method

A technology of constrained damping and noise reduction boards, applied in chemical instruments and methods, lamination, layered products, etc., can solve the problems of pore distribution affecting wheel imbalance, smaller bonding area, and high processing costs, and achieve good results Weather resistance, large bonding area, and good balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Embodiment 1: Preparation of the noise reduction board of the present invention

[0035] 1. Raw materials:

[0036] Steel plate (constrained layer), with an area of 800mm*800mm and a thickness of 2mm;

[0037] Polyurethane foam material (damping layer), with an area of 800mm*800mm and a thickness of 1.2mm;

[0038] Acrylate foam material (sound-absorbing layer), area 800mm*800mm, thickness 5mm, opening, pore diameter 0.5μm, porosity 30%; Adhesive: acrylate adhesive.

[0039] 2. Preparation method:

[0040] (1) Clean the surface of the steel plate to make the surface of the steel plate dry without cleaning agent residue;

[0041] (2) Evenly brush the acrylate adhesive on the surface of the steel plate, paste the polyurethane foam material on the surface of the steel plate, turn over the steel plate after curing, brush the acrylate adhesive on the surface of the steel plate on the other side, and paste the acrylate foam material Paste on the surface of the steel...

Embodiment 2

[0043] Embodiment 2: Preparation of the noise reduction board of the present invention

[0044] 1. Raw materials:

[0045] Copper plate (constrained layer), with an area of 800mm*800mm and a thickness of 3mm;

[0046] Rubber foam material (damping layer), with an area of 800mm*800mm and a thickness of 3mm;

[0047] Foam metal material (sound-absorbing layer), area 800mm*800mm, thickness 10mm, opening, pore diameter 100μm, porosity 50%;

[0048] Adhesive: Acrylic adhesive.

[0049] 2. Preparation method:

[0050] (1) Clean the surface of the steel plate to make the surface of the steel plate dry without cleaning agent residue;

[0051] (2) Evenly brush the acrylate adhesive on the surface of the steel plate, paste the polyurethane foam material on the surface of the steel plate, turn over the steel plate after curing, brush the acrylate adhesive on the surface of the steel plate on the other side, and paste the acrylate foam material Paste on the surface of the steel p...

Embodiment 3

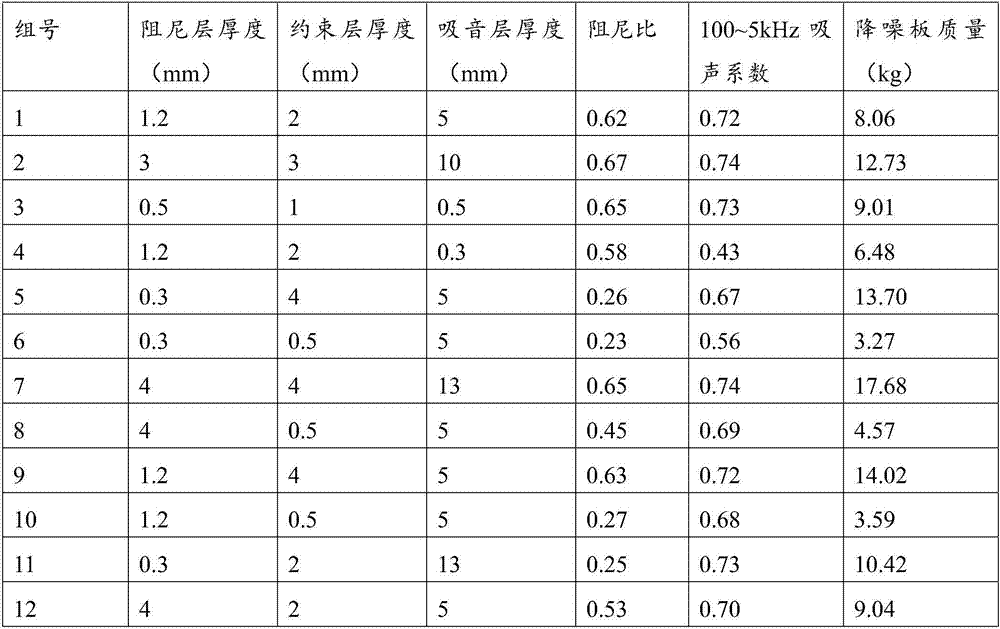

[0053] Embodiment 3: Performance test of the constrained damping type noise reduction panel of the present invention

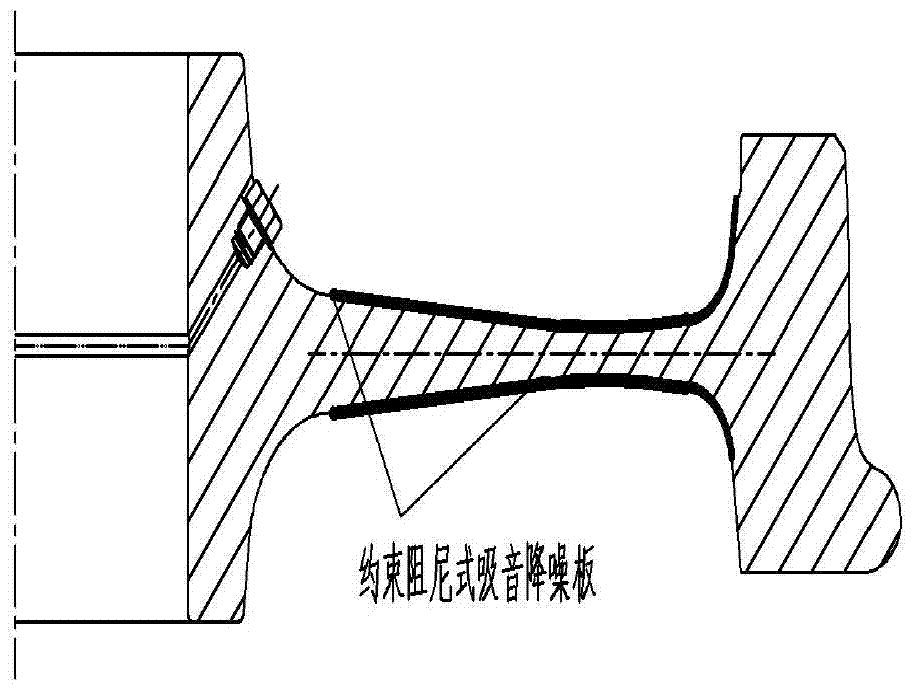

[0054] The constrained damping noise reduction plate prepared above was installed on the surface of the wheel web, and the damping ratio and sound absorption coefficient of the whole (the wheel with the noise reduction plate) were tested.

[0055] (1) The impact of the constrained layer of the present invention, the damping layer and the thickness of the sound-absorbing layer on the damping ratio and the sound absorption coefficient is shown in Table 1;

[0056] Table 1: Influence of thickness of constrained layer, damping layer and sound-absorbing layer on damping ratio and sound absorption coefficient according to the present invention:

[0057]

[0058]

[0059] Aiming at the performance of the constrained damping type noise reduction board, the invention comprehensively considers the damping ratio, the sound absorption coefficient and the quality o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com