Determining method for surface roughness of grinding of microcrystallite glass ceramic

A technology of glass-ceramics and surface roughness, which is applied in the field of engineering ceramics processing and can solve problems such as complex surface forming mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0145] A method for determining the surface roughness of glass-ceramic grinding, comprising the following steps:

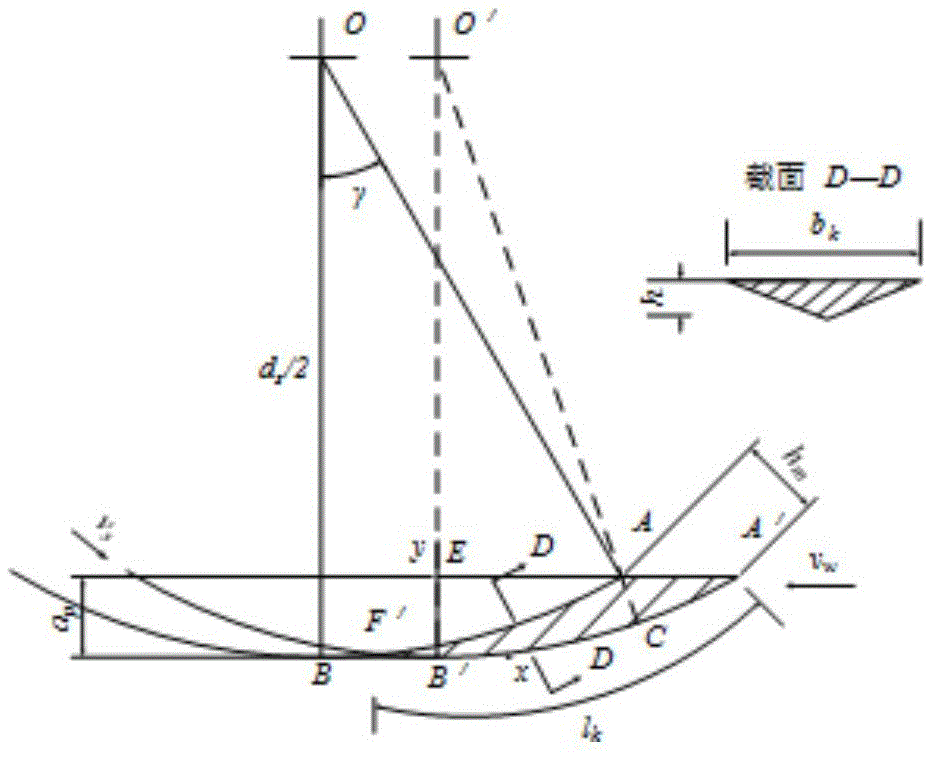

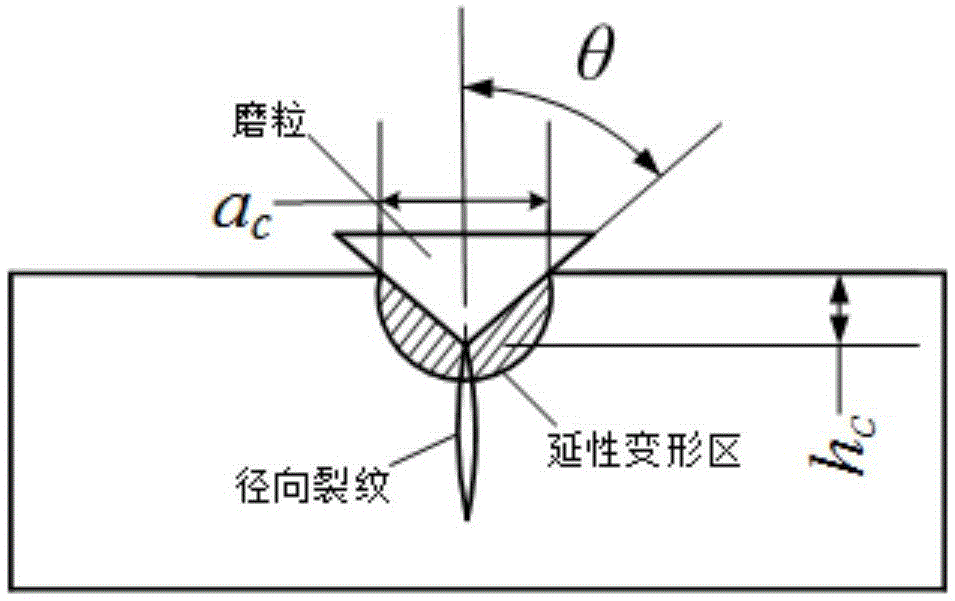

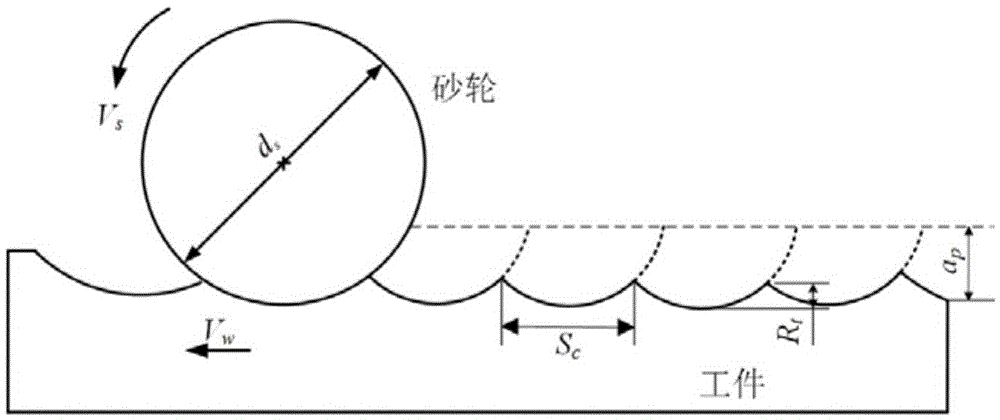

[0146] (1) According to the grinding processing conditions, the maximum undeformed chip thickness h can be obtained by the following formula max :

[0147] h m a x = ( 3 N d tan θ ) ( v w v s ) ( a p d s ) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com