A rotary turbulent flow mixer

A turbulent mixing and rotary technology, which is applied in mixers, shaking/oscillating/vibrating mixers, dissolution, etc., can solve the problems of low mixing efficiency and difficulty in uniform dispersion, so as to improve the dispersion effect, facilitate maintenance, and reduce manufacturing costs. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Specific embodiments of the present invention will be described below with reference to the accompanying drawings.

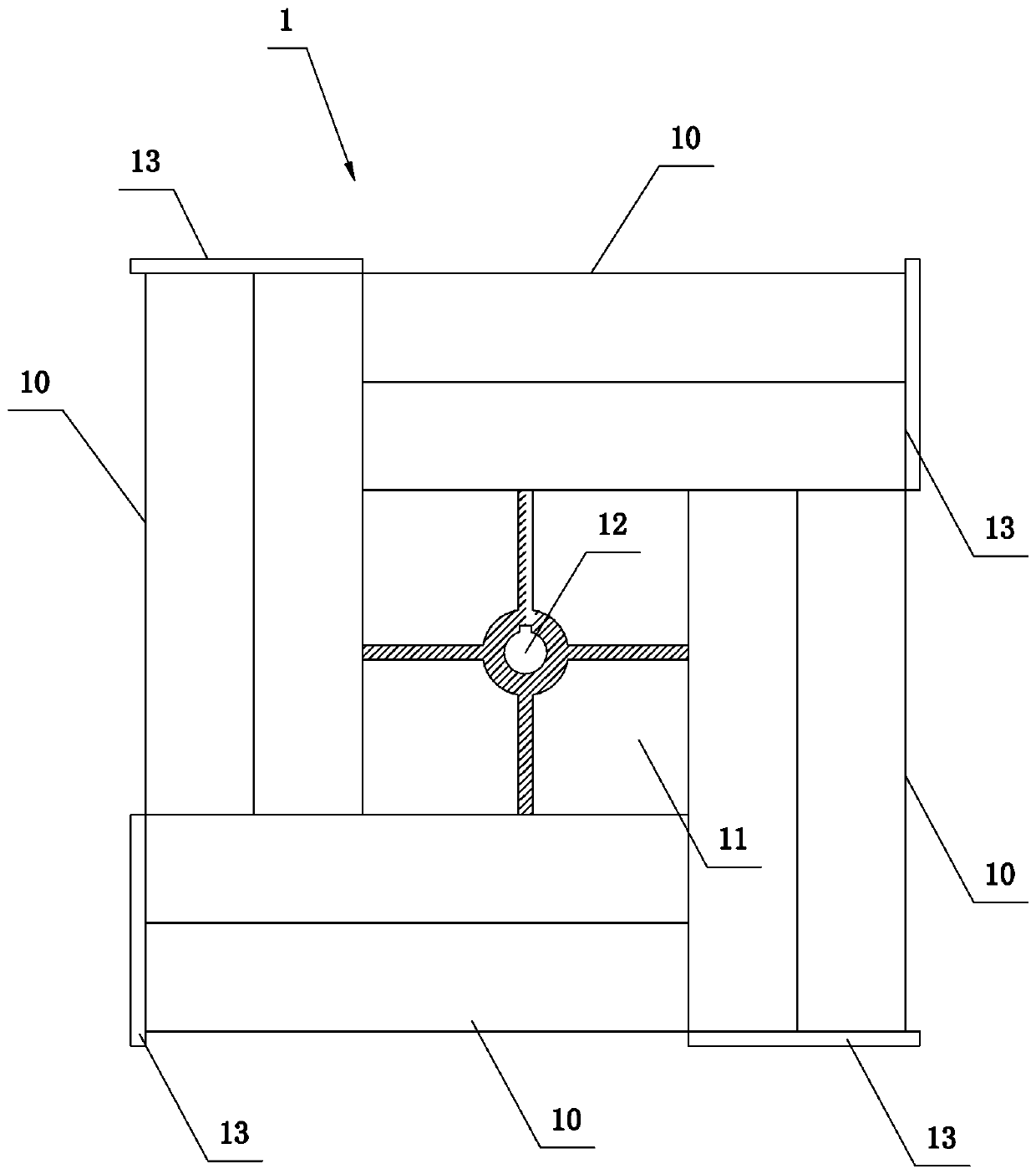

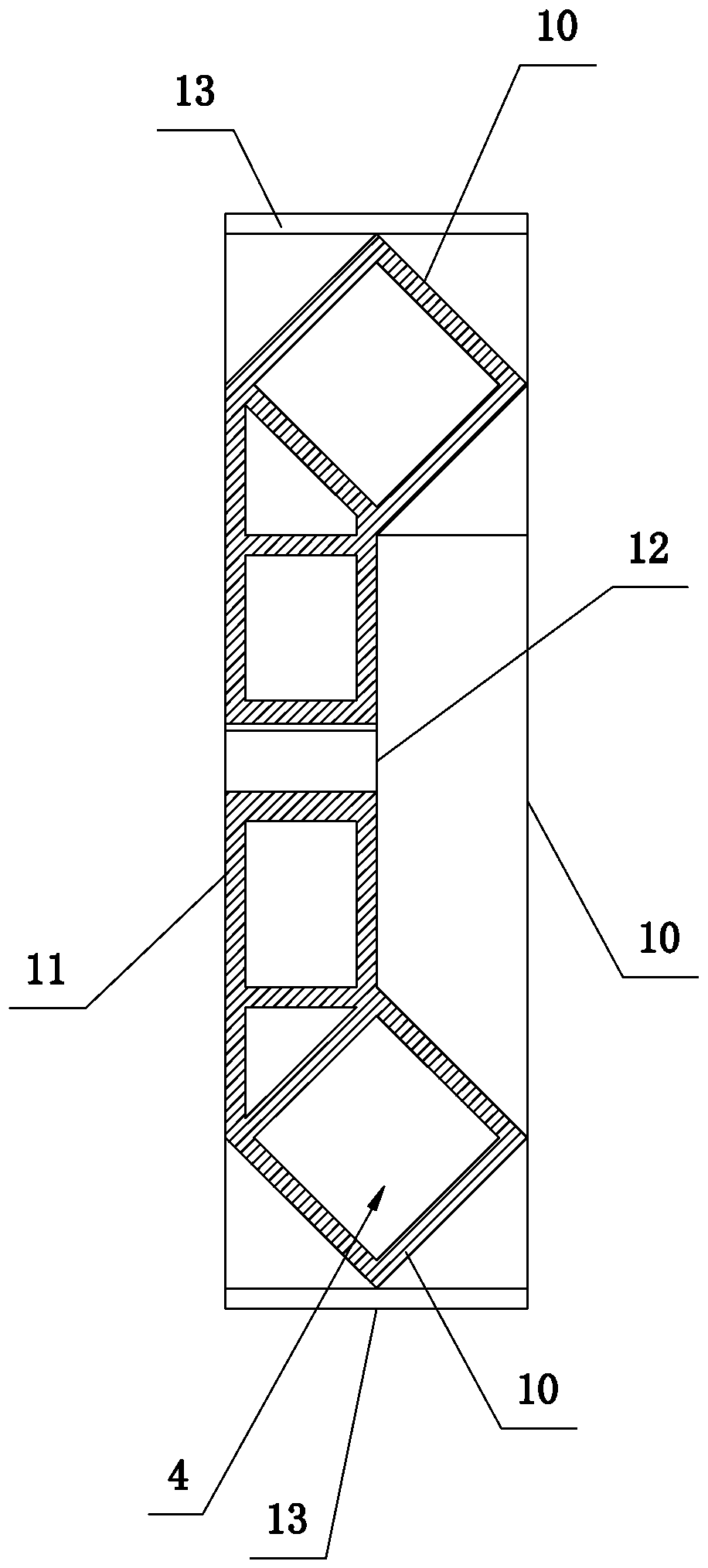

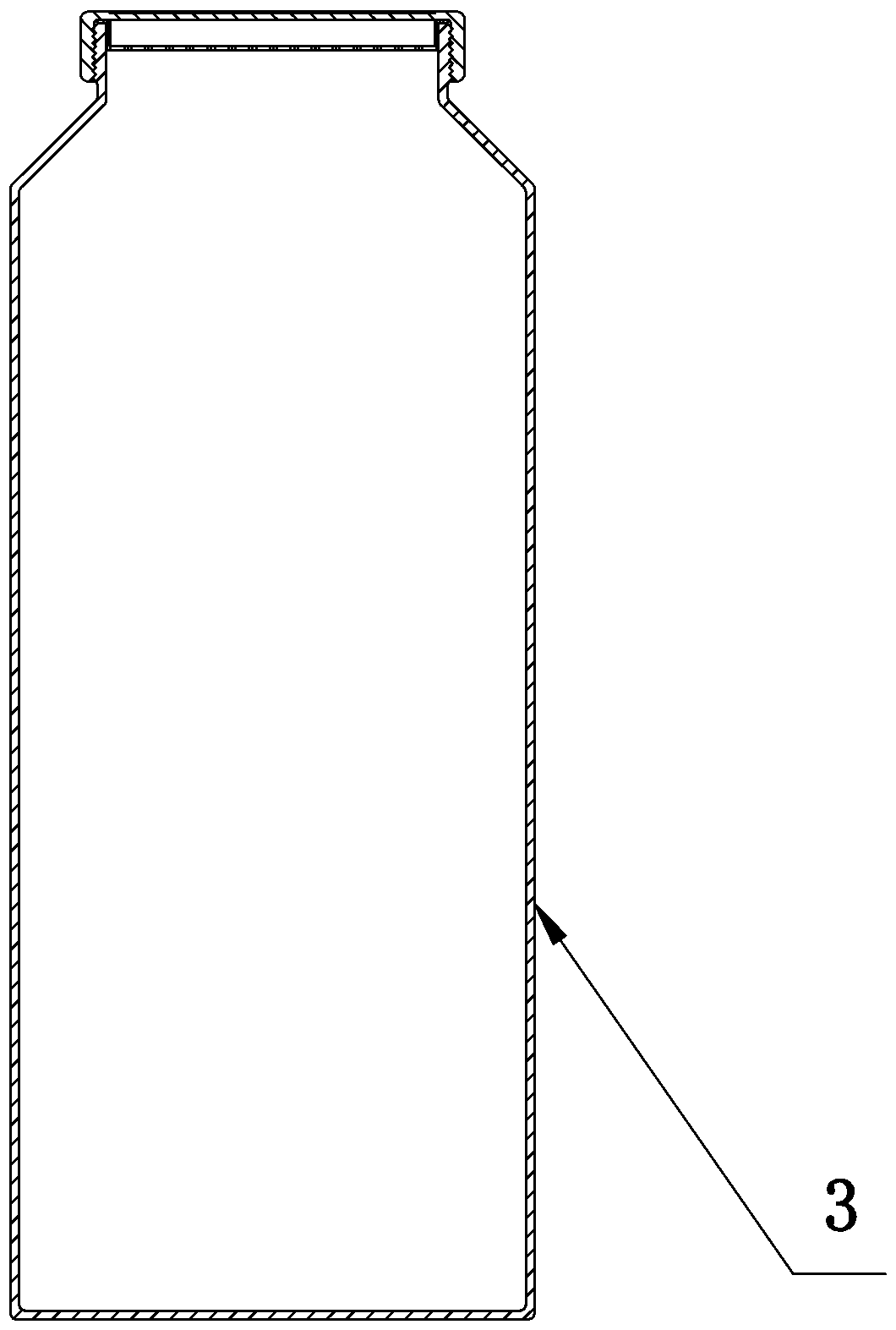

[0026] refer to figure 1 , figure 2 , image 3 with Figure 4 . A rotary turbulent flow mixer, comprising a driving device, a mounting support 1 driven by the driving device to rotate around a horizontal axis, and a plurality of mixing barrels 3 with a built-in mixture 2, the mounting support 1 A plurality of assembly grooves 4 for installing the mixing bucket 3 are arranged at the outer rotation circumference position thereof. By setting the mixing tank 3 so that it can rotate up and down around the horizontal axis, during the rotation process, the self-gravity of the mixture 2 in it is fully utilized, so that the upward movement forms a powerful impact on the downward movement of the mixture 2, which is beneficial to the mixing. The dispersion of 2 can not only ensure that the mixture 2 is dispersed in each position in the mixing tank 3, and the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com