Quantitative distribution device capable of accurately distributing materials and food processor thereof

A food processing machine and quantitative distribution technology, which is applied in beverage preparation devices, household appliances, applications, etc., can solve the problems of complex structure, powder outlet bonding, cost increase, etc., and achieve the effect of accurate material quantification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

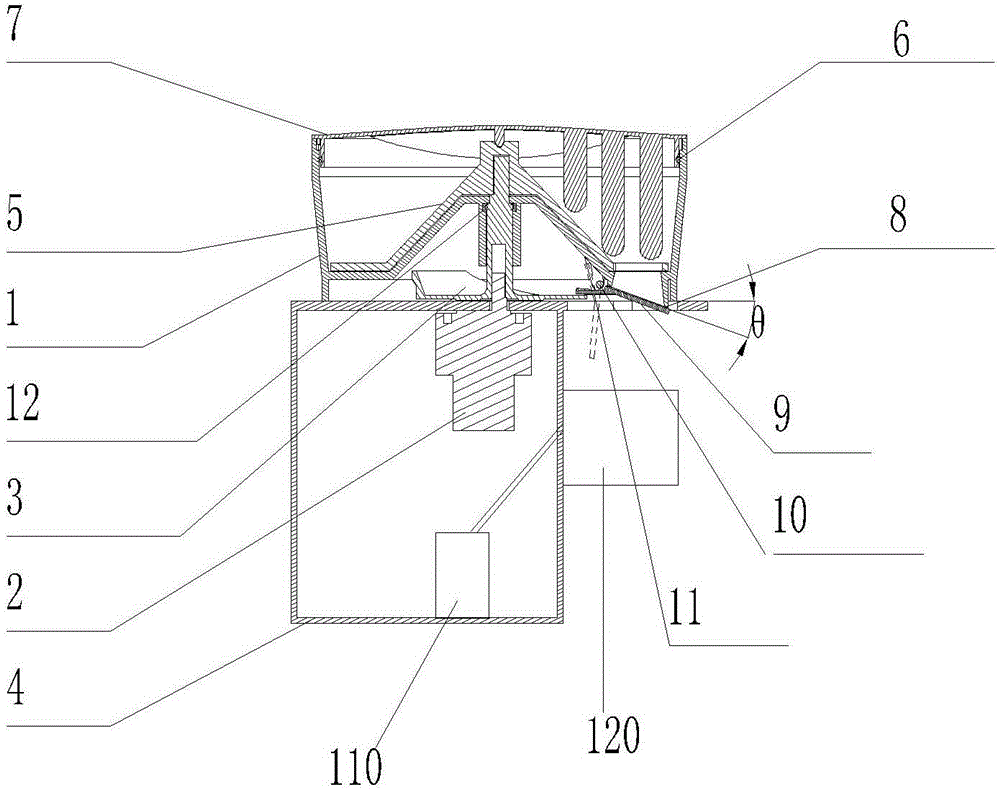

[0038] Such as figure 1 As shown, a quantitative distribution device for accurately distributing materials, the quantitative distribution device includes a silo 1, a motor 2, the motor 2 is installed below the silo 1, the quantitative distribution device also includes a quantitative powder outlet channel 41 and a The rotating disk 5 in the silo 1 and driven by the motor 2, the bottom of the silo 1 is provided with an opening 46, the opening 46 is connected with the quantitative powder outlet channel 41, and the opening 46 is the quantitative powder outlet channel 41 on the port.

[0039] Such as figure 2As shown, the edge of the lower port of the quantitative powder outlet channel 41 is provided with a sealing groove 44, and the sealing groove 44 is provided with a lower sealing ring 8. An upper sealing ring 6 is provided on the end surface, and the upper sealing ring 6 is assembled into the upper cover 7, and the upper cover 7 and the silo 1 are fixed in it by fastening, a...

Embodiment 2

[0048] This embodiment is an improvement made on the basis of Embodiment 1, specifically as Figure 4 , Figure 5 As shown, the width of the lower powder opening 51 is not less than the equivalent diameter of the upper port of the quantitative powder outlet channel 41, and the lower powder opening 51 extends along the circumferential direction of the rotating disk and is arranged in a fan ring shape. The central angle corresponding to the ring is δ, where 60°≤δ180°, only one powder lowering port 51 can be set, not It is beneficial to improve the powder output efficiency, and this scheme δ=110°.

[0049] The rotational speed of the rotating disk 5 is A, where 30r / min≤A≤150r / min. r / min refers to how many revolutions per minute, A is 45r / min in this embodiment. The advantage of this setting is: by limiting the rotational speed A of the rotating disc 5, the powder lowering port 51 can improve the powder falling efficiency under the premise of ensuring the quantitative powder du...

Embodiment 3

[0057] The third embodiment is an improvement made on the first or / and second embodiment. The lower port of the quantitative powder outlet channel 41 is an inclined opening, and the baffle 9 is arranged at the inclined opening. The inclination angle of the inclination port is θ, and the baffle plate 9 is also inclined accordingly, where 0°<θ≤45°. In this embodiment, θ is 20°. The advantage of this setting is: when θ is greater than 45 degrees, the inner wall of the quantitative disposal channel is too long, which will cause the material to easily adhere to the inner wall, and thus be affected by moisture and deteriorate. In addition, the space for the material to fall is extended, and the sealing effect is higher. , and the tightness is also reduced accordingly.

[0058] Such as Figure 7 As shown, the rotating disc 5 includes a conical body 54 and an annular plate 55 located at the edge of the conical body 54, the powder lowering port 51 is arranged on the annular plate 55,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com