A kind of production method of fish head paste rich in polyunsaturated fatty acid

The technology of an unsaturated fatty acid and a production method is applied in the production field of fish head paste rich in polyunsaturated fatty acids, and can solve the problems of high unsaturated fat content in fish belly meat, easy oxidative loss of unsaturated fatty acids, and high cost of high-pressure heat treatment, Achieve the effect of low cost, mechanized processing and efficient utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

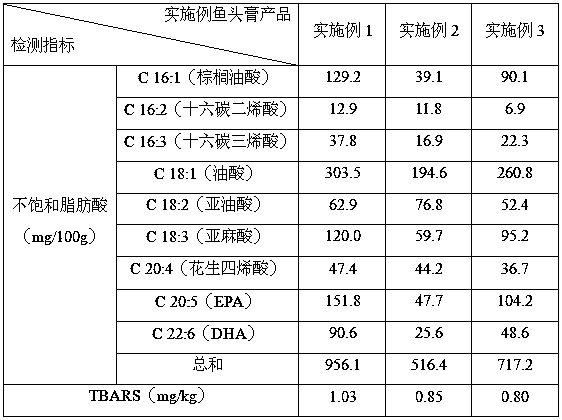

Examples

Embodiment 1

[0037] The preparation method of the deodorizing agent used in this example: add 200mL water to 10g active dry yeast powder, activate at room temperature for 2 hours, then add 20g Vc, replenish water to 2200g, cool to 5°C, and set aside.

[0038] (1) Wash and chop 1000g of fresh silver carp head with gills removed, add 2000g of the deodorizing agent, homogenize with a homogenizer, add 0.2mol / L acetic acid dropwise, adjust the pH value to 2.0, and stir for 40min. Suction filtration, collect filtrate, obtain 2450g boneless silver carp head slurry;

[0039] (2) Wash 150 g of silver carp belly meat, add 160 g of the deodorizing agent, homogenize with a homogenizer, and filter to obtain 300 g of silver carp belly meat slurry;

[0040] (3) Mix 2450g of boneless silver carp head slurry obtained in step (1) with 300g of silver carp belly meat slurry obtained in step (2), add 3.0g of gum arabic and 3.0g of monoglyceride, and then dropwise add 0.2mol / L of Sodium carbonate, adjust the p...

Embodiment 2

[0044] The preparation method of the deodorizing agent used in this example: add 1000mL of water to 200g of fresh ginger, homogenate with a homogenizer, boil, filter to obtain ginger juice, cool to room temperature, add water to 4500g, add 20g of acetic acid bacteria Bacteria powder, cooled to 10°C, set aside.

[0045] (1) Wash and chop 1000g fresh head of bighead carp with gills removed, add 4000g of the deodorizing agent, homogenate with a homogenizer, add 0.2mol / L acetic acid dropwise, adjust the pH value to 2.3, and stir for 50min. Suction filtration, collect filtrate, obtain 4500g boneless bighead carp head slurry;

[0046] (2) Wash 250 g of bighead carp belly meat, add 500 g of the deodorizing agent, homogenize with a homogenizer, and filter to obtain 740 g of bighead carp belly meat slurry;

[0047] (3) Mix 4,500g of boneless bighead carp head paste obtained in step (1) with 740g of bighead carp belly pulp obtained in step (2), add 5.0g of gelatin and 5.0g of sucrose e...

Embodiment 3

[0051] The preparation method of the deodorizing agent used in this example: add 200mL of water to 20g of active dry yeast powder, activate at room temperature for 2 hours, then add 50g of Vc, replenish water to 3000g, cool to 15°C, and set aside.

[0052] (1) Wash and chop 1000g of fresh silver carp head with gills removed, add 2500g of the deodorizing agent, homogenize with a homogenizer, add 0.2mol / L lactic acid dropwise, adjust the pH value to 2.5, and stir for 20min. Suction filtration, collect filtrate, obtain 3000 g boneless silver carp head slurry;

[0053] (2) Add 4.5 g of gelatin and 4.5 g of monoglyceride to the 3,000 g boneless silver carp head slurry obtained in step (1), then add 0.2 mol / L of sodium carbonate dropwise, adjust the pH to 4.0, and homogenize with a homogenizer slurry, to get 3000g mixed silver carp head meat slurry;

[0054] (3) Add 100g shredded ginger, 200g tempeh and 200g salt to 3000g silver carp head meat slurry obtained in step (2), mix well,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com