Conductive line and wiring structure thereof

A technology of conductive wires and wires, which is applied in the direction of conductive connections, parts of conductive cores, conductors, etc., can solve the problems of difficult thinning of twisted wires and increased costs, and achieve effective utilization, good bendability, and realization of lightweight effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

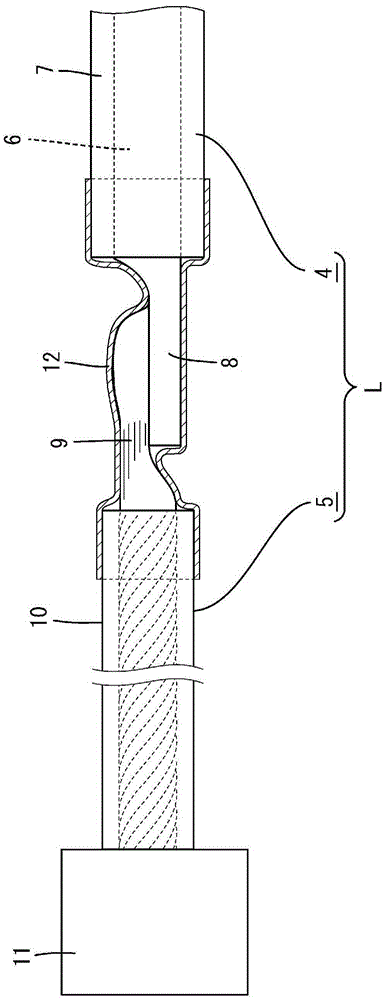

Embodiment 1

[0032] The conductive wire L of this embodiment is suitable for a hybrid vehicle. The battery 1 mounted on the rear side of the vehicle and the inverter 2 installed in the engine room are connected by a wire harness WH. In the case of this example, if Figure 4 As shown, the wire harness WH is composed of three conductive wires L.

[0033] The wire harness WH is collectively inserted into the shield pipe 3 arranged under the floor of the vehicle. More specifically, the rear end side of the shield pipe 3 is introduced into the rear suspension side of the vehicle compartment, and a metal braid 13 to be described later is interposed between the shield pipe 3 and the battery 1 . The middle of the shield pipe 3 extends substantially horizontally under the floor of the vehicle along the front-rear direction. Its front end is bent upward and introduced into the engine room, and extends toward the inverter 2 .

[0034] The shielding tube 3 is made of aluminum or an aluminum alloy,...

Embodiment 2

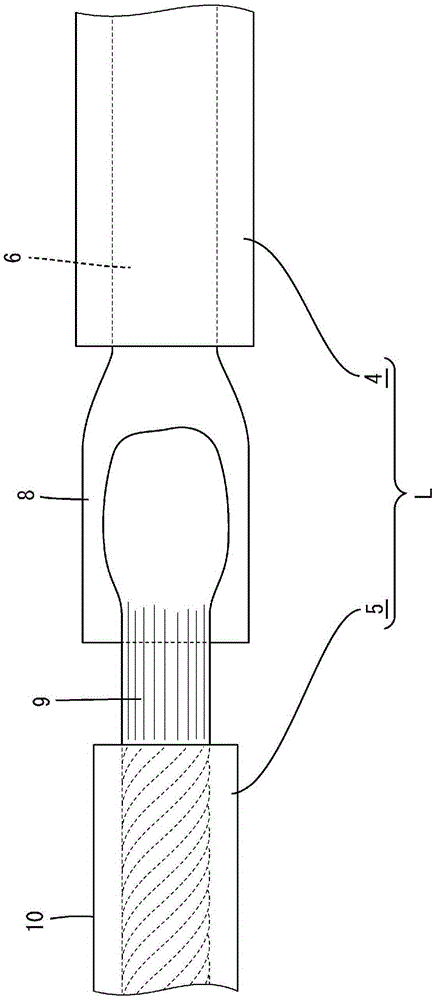

[0048] Figure 5 Example 2 of the present invention is shown. In Embodiment 1, the mode in which the conductor 6 exposed at the front end of the single-core wire 4 and the wire 9 exposed at the rear end of the twisted wire 5 are bonded and connected by ultrasonic welding is shown, but in Embodiment 2 connection by riveting. That is, the portion of the conductor 6 exposed from the single-core electric wire 4 is crushed and spread sufficiently in the width direction to form a pair of crimped portions 6A. The wire rod 9 portion of the twisted electric wire 5 is placed on the crushed portion 8 formed in this way, and both sides in the width direction are bent inward together and caulked. In this way it is also possible to connect single-core wires 4 and stranded wires 5 .

[0049] The other structures are the same as those in Embodiment 1, and can also exert the same effects.

Embodiment 3

[0051] Image 6 Example 3 of the present invention is shown. In Example 2, the cross section of the conductor 6 was formed square and the wire 9 was riveted, but in Example 3 the cross section was formed circular and the wire 9 was riveted.

[0052] The other structures are the same as in Embodiments 1 and 2, and can also exert the same effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com