Wearable type flexible temperature-difference power generation structure with stretchable wire

A thermoelectric power generation and wearable technology, which is applied in the direction of generators/motors, electrical components, thermoelectric device parts, etc., can solve problems such as failure of thermoelectric power generation units, poor mechanical properties, fracture deformation, etc., to increase temperature difference and reduce Structural thickness and mass, effects of avoiding failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

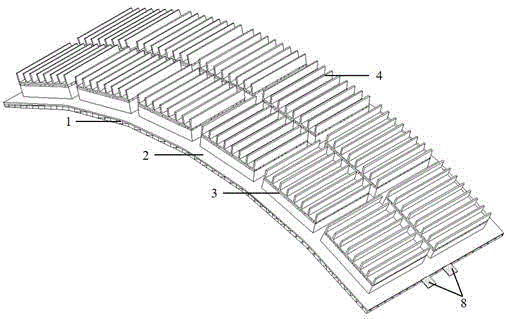

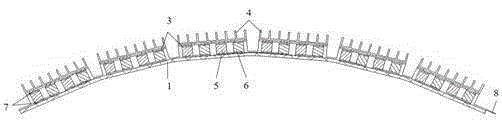

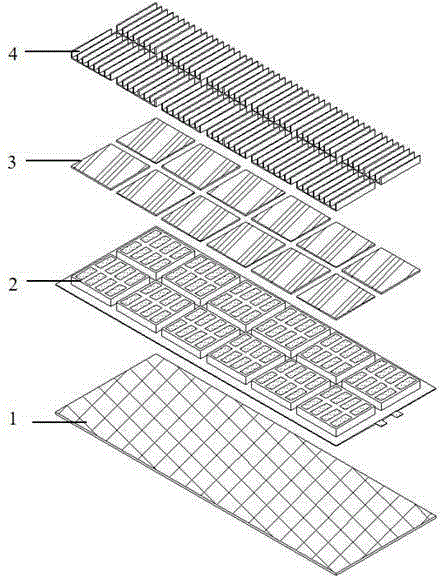

[0020] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0021] Basic principle of the present invention is:

[0022] According to the Seebeck effect, the temperature difference across the P-type thermoelectric arm and the N-type thermoelectric arm produces a voltage difference. Since the voltage generated by a single thermocouple is very low, the P-type and N-type thermoelectric arms can be formed into a thermoelectric array by adopting the method of "parallel connection of thermal circuits and series connection of circuits", thereby increasing the output voltage value.

[0023] Bismuth telluride materials have the highest thermoelectric figure of merit at room temperature, and the use of bismuth telluride and its alloys can increase the power generation of thermoelectric power generation devices. However, due to the poor mechanical properties of bismuth telluride materials, stress can easily lead to fractu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com