Springs for preloading rolling bearings and structural components with springs and rolling bearings

A technology of structural components and preloaded bearings, applied in the spring field of preloaded rolling bearings, which can solve the problems that the deformation characteristics of elastic springs are not linear and cannot be monitored

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

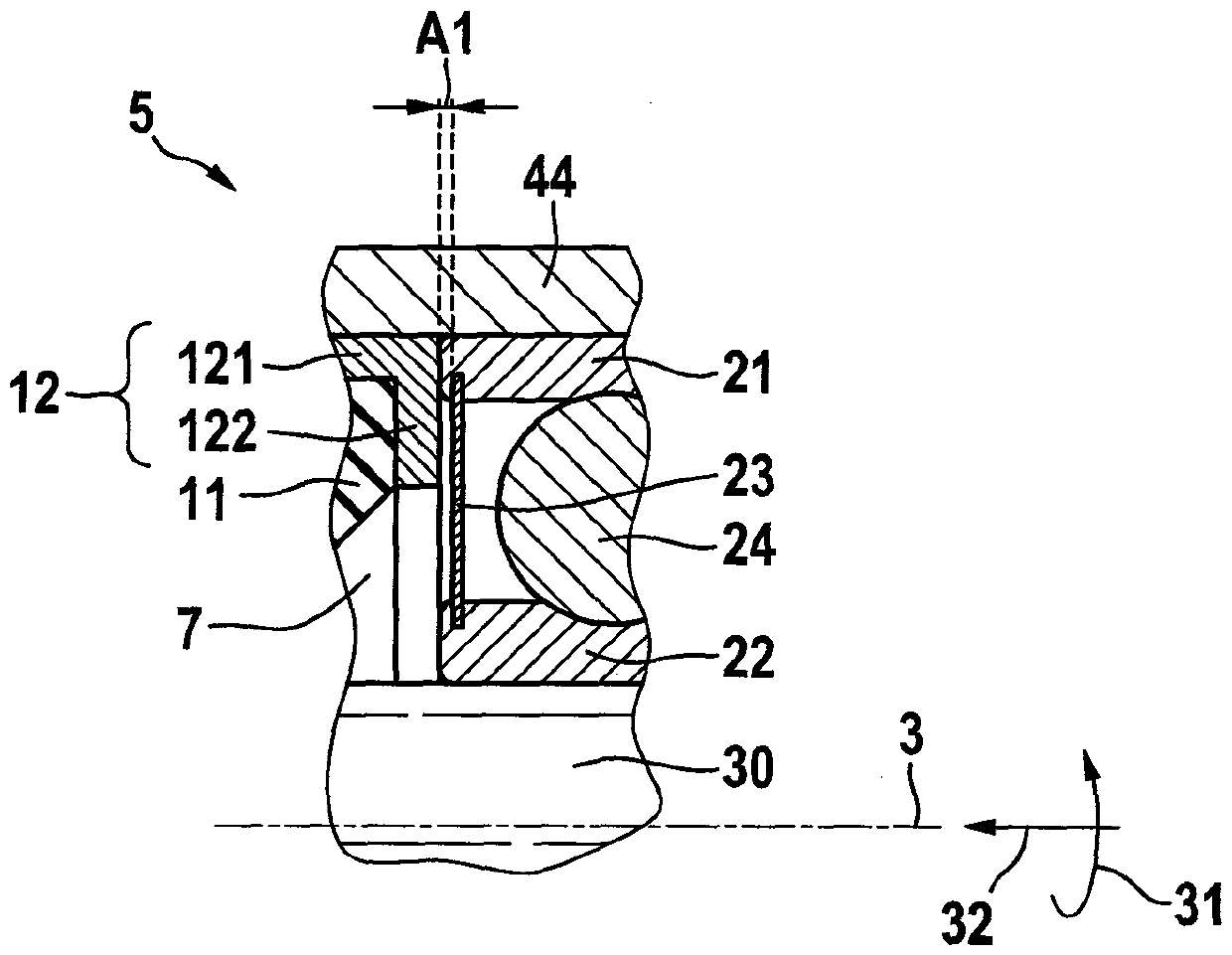

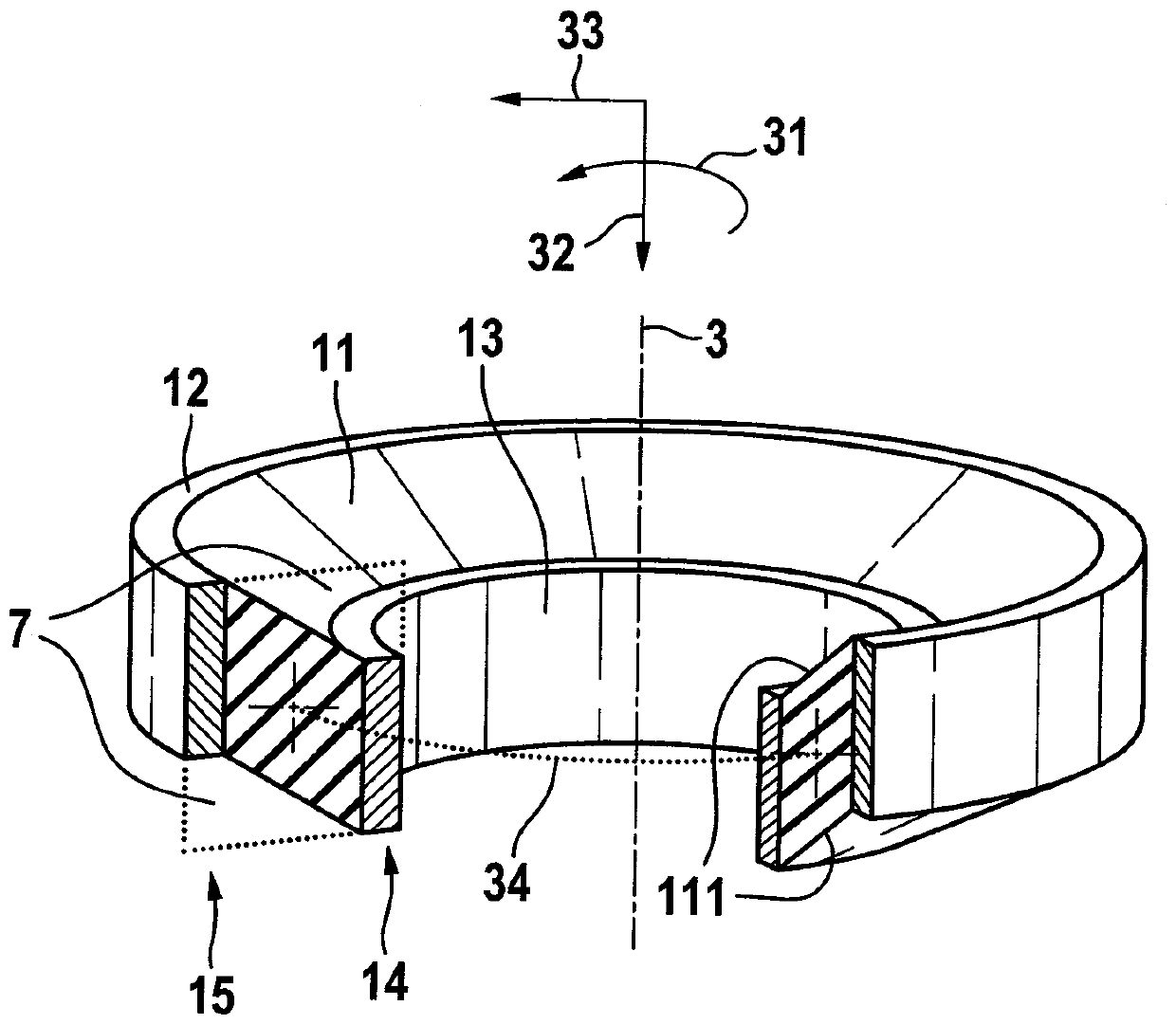

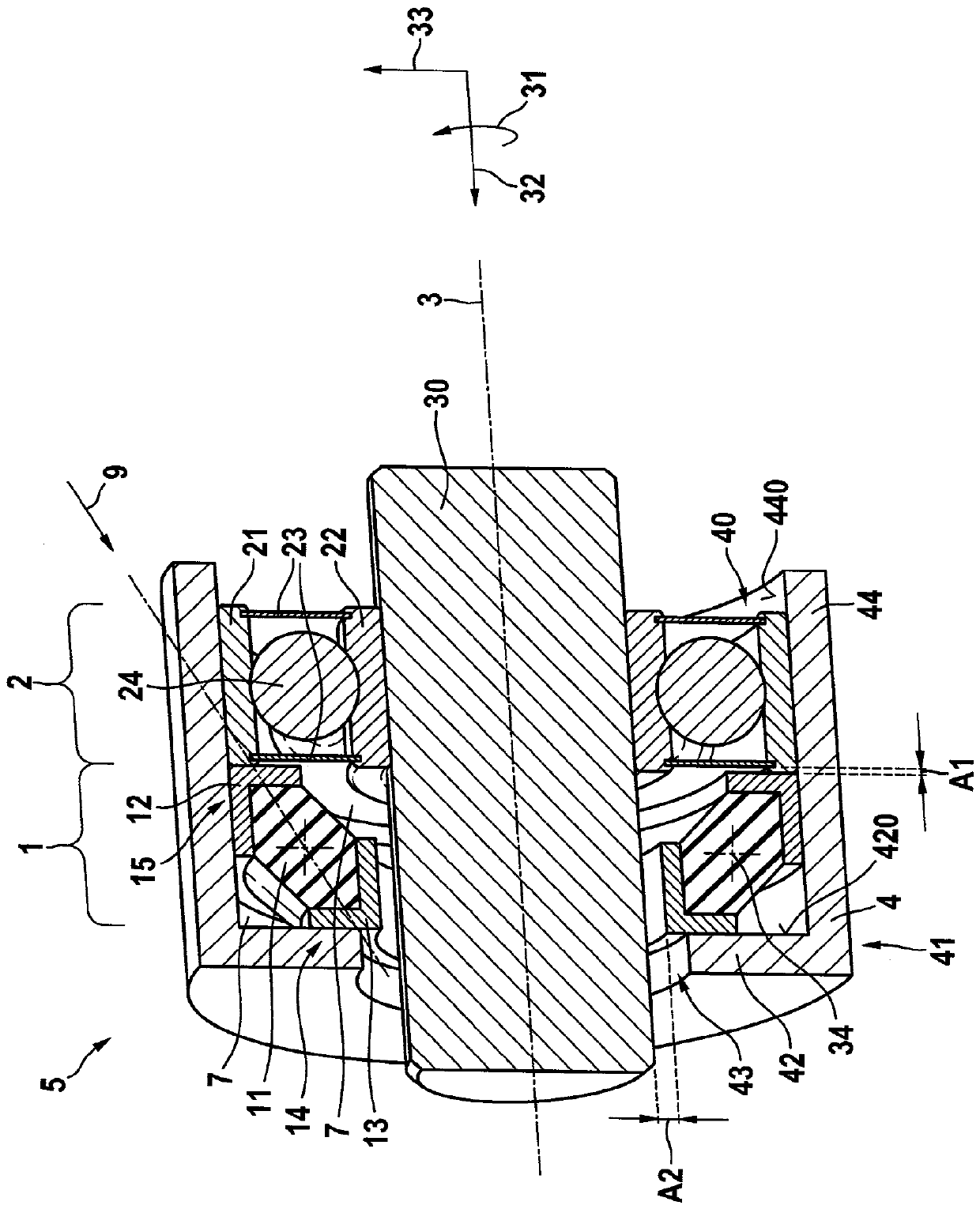

[0033] The structural component 5 has a shaft 30 which is arranged concentrically around the axis 3 and extends in a longitudinal direction 32 . Roller bearing 2 is arranged on shaft 30 concentrically to axis 3 . The rolling bearing 2 shown here has balls as rolling bodies 24 . The terms rolling body and ball are used synonymously below. However, the invention also extends to rolling bearings 2 having other, for example cylindrical or conical rolling bodies 24 .

[0034] The balls 24 are arranged between an inner ring 22 arranged in a rotationally fixed manner on the shaft 30 and an outer ring 21 arranged in a rotationally fixed manner on the housing part 4 . In order to prevent the balls 24 from becoming dirty and falling out, bearing caps 23 are provided on both sides of the balls 24 , which extend transversely (perpendicularly) to the shaft 30 and between the inner and outer rings 21 , 22 . The bearing caps 23 arranged on both sides of the sphere 24 are arranged inwardly...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com