Antibacterial and mildewproof rubber-plastic shoe material and preparation method thereof

An antibacterial and antifungal, rubber and plastic technology, applied in the field of shoe materials, can solve the problems of moldy shoes, short lasting effect, and indirect antibacterial effect, and achieve the effect of maintaining antibacterial properties, long lasting and good antibacterial effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

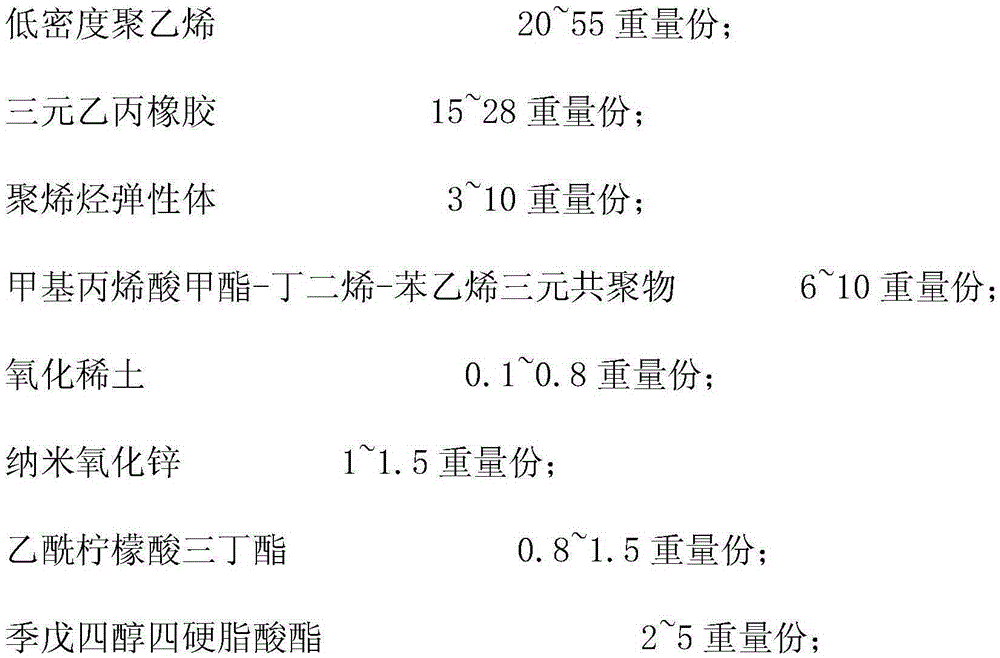

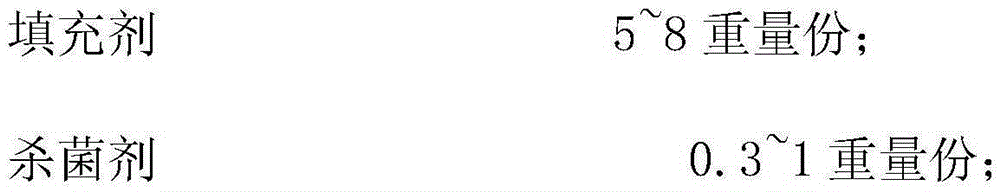

[0028] The antibacterial and mildew-resistant rubber and plastic shoe material comprises the following components by weight: 20 parts of low-density polyethylene; 15 parts of EPDM; 3 parts of polyolefin elastomer; methyl methacrylate-butadiene-styrene 6 parts of terpolymer; 0.1 part of rare earth oxide; 1 part of nano-zinc oxide; 0.8 part of acetyl tributyl citrate; 2 parts of pentaerythritol tetrastearate; 5-8 parts of calcium carbonate;

[0029] The fungicide is a microcapsule structure with a particle size range of 10-100 μm, a thickness ratio of the wall material to the core layer of 1:15-1:22, and the core layer is surface-treated with a borate coupling agent in a mass ratio of 3: 1 silver-loaded phosphate and zinc-loaded phosphate composite powder, and the wall material is polyester film.

Embodiment 2

[0031] The antibacterial and mildew-proof rubber and plastic shoe material comprises the following components by weight: 30 parts of low-density polyethylene; 25 parts of EPDM rubber; 7 parts of polyolefin elastomer; methyl methacrylate-butadiene-styrene 8 parts of terpolymer; 0.5 parts of rare earth oxide; 1.2 parts of nano zinc oxide; 1 part of acetyl tributyl citrate; 3 parts of pentaerythritol tetrastearate; 7 parts of calcium carbonate; 0.6 parts of fungicide.

[0032] The fungicide is a microcapsule structure with a particle size range of 10-100 μm, a thickness ratio of the wall material to the core layer of 1:15-1:22, and the core layer is surface-treated with a borate coupling agent in a mass ratio of 3: 1 silver-loaded phosphate and zinc-loaded phosphate composite powder, and the wall material is polyester film.

Embodiment 3

[0034] The antibacterial and mildew-proof rubber and plastic shoe material comprises the following components by weight: 55 parts of low-density polyethylene; 28 parts of EPDM rubber; 10 parts of polyolefin elastomer; methyl methacrylate-butadiene-styrene 10 parts of terpolymer; 0.8 parts of rare earth oxide; 1.5 parts of nano zinc oxide; 1.5 parts of acetyl tributyl citrate; 5 parts of pentaerythritol tetrastearate; 8 parts of filler; 1 part of fungicide.

[0035] The fungicide is a microcapsule structure with a particle size range of 10-100 μm, a thickness ratio of the wall material to the core layer of 1:15-1:22, and the core layer is surface-treated with a borate coupling agent in a mass ratio of 3: 1 silver-loaded phosphate and zinc-loaded phosphate composite powder, and the wall material is polyester film.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com